2 KODAK AEROCOLOR III Negative Film 2444 • AS-116

Typical Camera Exposure

A typical exposure for this film, in an aerial camera with a

2X antivignetting filter, is approximately 1⁄750 second at

f⁄5.6. This exposure is based on a solar altitude of 40 degrees,

a clear day, and an aircraft altitude of 5000 feet.

Reciprocity Characteristics

No filter correction or exposure adjustment is required for

exposure times from 1⁄10,000 second to 1⁄10 second.

IMAGE STRUCTURE

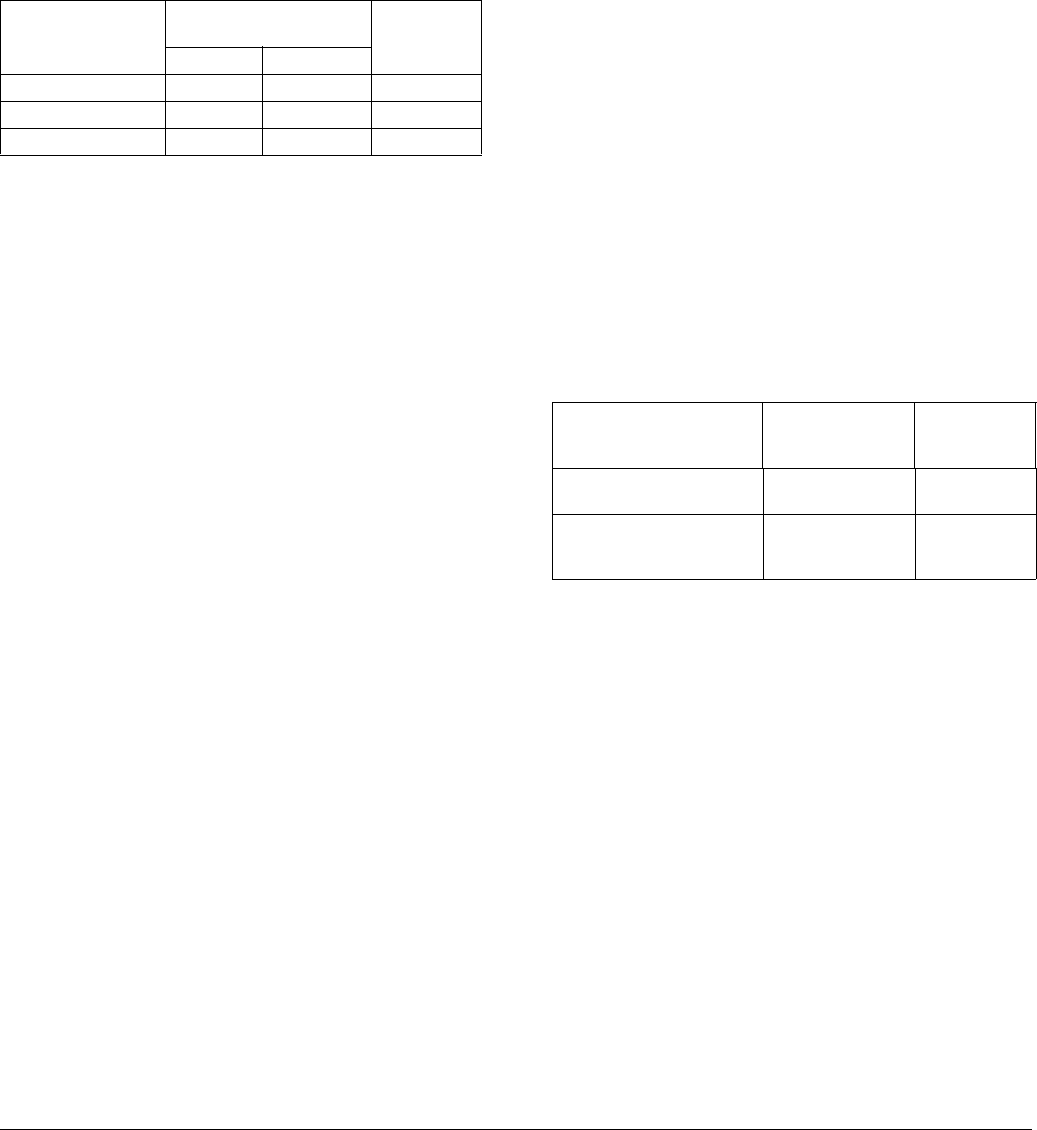

*

Granularity values read at a net green diffuse density of 1.0 with a

48-micrometre aperture.

STORAGE

For consistent results, all aerial films should be stored under

fairly constant conditions. Kodak aerial films are “usually”

packaged in equilibrium with 40 to 50 percent relative

humidity. High temperatures or high humidity may produce

undesirable changes in the film. Color films are more

seriously affected by adverse storage conditions than are

black-and-white films. These adverse conditions affect the

three emulsion layers to different degrees, thus causing

changes in the color balance, as well as possible changes in

overall film speed and contrast.

Unexposed Film

While this film has exceptionally good rawstock keeping

characteristics at room temperature, it is recommended that

film that will not be exposed within two weeks be stored in a

refrigerator at 55°F (13°C) or lower, or freezer at 0 to -10°F

(-18 to -23°C), in the original sealed container. If the film is

stored in a refrigerator, remove it about 2 hours before

opening; if stored in a freezer, remove it about 8 hours before

opening. A sufficient warm-up time is necessary to prevent

moisture condensation on cold film—otherwise, moisture

spotting, ferrotyping, or sticking may occur.

Exposed Film

Although this film has excellent latent-keeping properties, it

remains prudent to keep exposed film cool and dry whenever

practical. Process the film as soon as possible after exposure

to avoid undesirable changes in the latent image. If it is

necessary to hold exposed but unprocessed film for more

than a week, it should be resealed and refrigerated at 40°F

(4°C) or lower. Before unsealing and processing exposed

film that has been held in cold storage, follow the warm-up

procedures described above for unexposed film.

Process

Resolving Power

(line pairs/mm)

rms

Granularity

*

TOC 1.6:1 TOC 1000:1

AN-6, 3:00 dev time 80 100 16

C-41, 4:15 dev time 80 125 15

C-41, 3:15 dev time 80 125 10

Processed Film

For best keeping, store processed film in a dark, dust-free

area at 50 to 70°F (10 to 21°C) and 30 to 50 percent relative

humidity. Preferably, store negatives on the spool or in

individual KODAK Sleeves. High relative humidity

promotes the growth of mold and causes ferrotyping. Very

low relative humidity causes excessive curl and brittleness.

Avoid storage temperatures over 80°F (27°C).

Caution! Do not freeze processed AEROCOLOR III

Color Negative Film 2444. Freezing processed film can

cause coupler alterations.

PROCESSING

The primary recommendation for processing 2444 Film is in

Process AN-6 using mechanized processors. Mechanized

processing in roller-transport processors offers the

advantages of uniform treatment of all portions of the roll,

freedom from banding, and absence of significant density

variations from ends of the roll to the center.

Note: Contrast may be easily tailored over a range of

approximately 0.65 to 0.95 gamma to suit various

acquisition and personal preferences. The following tables

for Process AN-6 pertain to the highest contrast option; a

table at the end of this section lists both AN-6 and C-41

developer time/temperature options to achieve a variety of

desired contrasts.

Process AN-6 Cycle Times

In each case, the film is fed emulsion side down into the

processor.

This publication provides general information regarding

the KODAK Aerial Color Processor, Model 1611, and the

KODAK EKTACHROME RT Processor, Model 1811.

Refer to the operating manuals for additional set-up

information.

Note: For a list of firms equipped to offer machine

processing of 2444 Film, send an e-mail to

aerial@kodak.com or write to Eastman Kodak Company,

Aerial Imaging, Rochester, New York 14653-7128.

Processor

Transport Speed

(feet per minute)

Dry-to-Dry

Processing

Time

KODAK Aerial Color

Processor, Model 1611

4.2 11.8 minutes

KODAK EKTACHROME

RT Processor, Model

1811 (with Quick-Change)

4.2 11.6 minutes