2 KODAK DOUBLE-X AEROGRAPHIC Film 2405 • AS-75

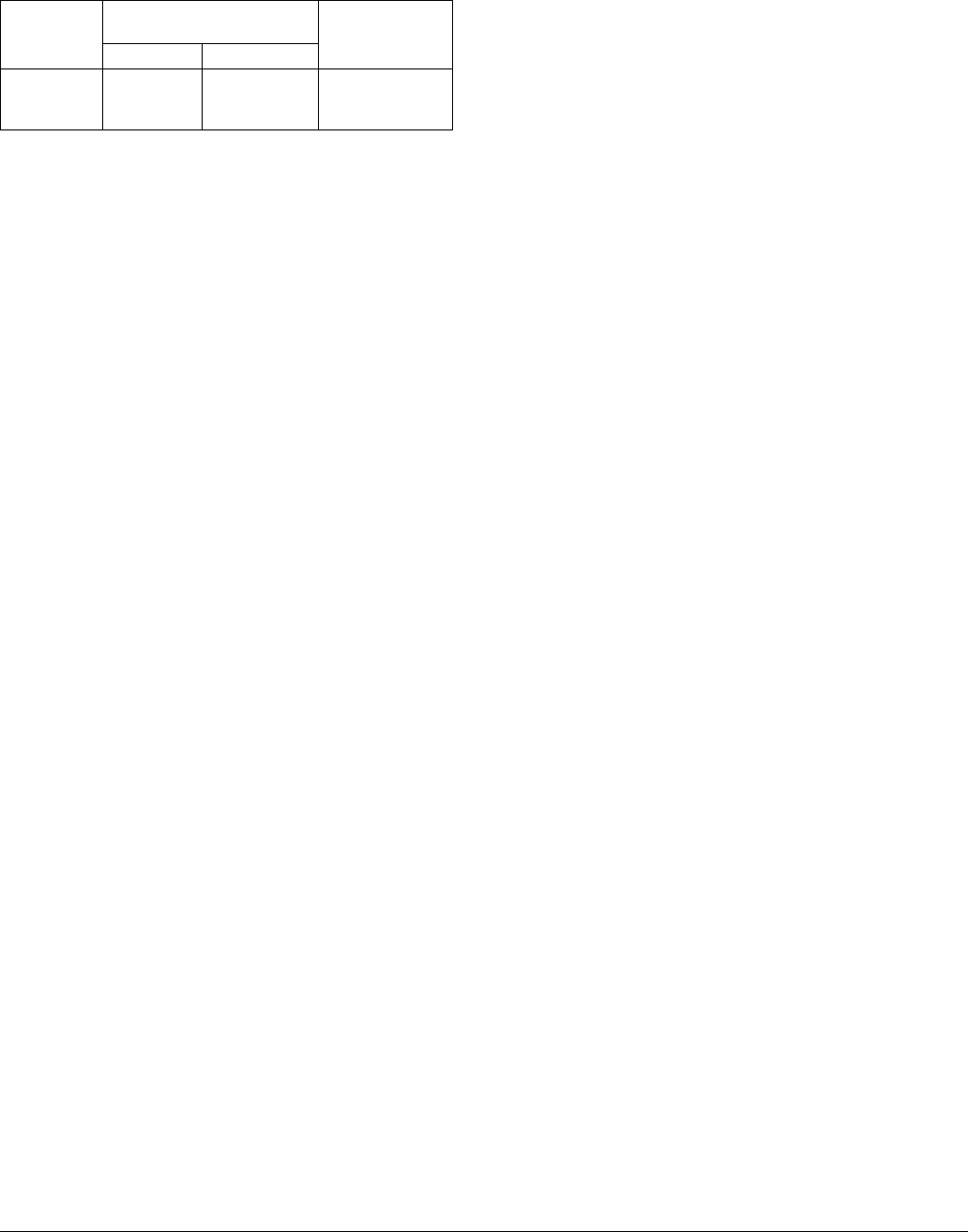

IMAGE STRUCTURE

The following data are based on processing in KODAK

VERSAMAT Film Processors, Model 11, using KODAK

VERSAMAT Chemicals at the conditions noted.

*

Granularity values read at a net diffuse density of 1.0 with a

48-micrometre aperture.

Process conditions to achieve above values:

885 Chemicals:15 fpm, 85°F (29.5°C), process gamma 1.10

641 Chemicals: 5 fpm, 85°F (29.5°C), process gamma 1.30

Type A Chemicals: 10 fpm, 90°F (32°C), process gamma

1.65

STORAGE

For consistent results, all aerial films should be stored under

fairly constant conditions. Kodak aerial films are “usually”

packaged in equilibrium with 40 to 50 percent relative

humidity. High temperatures or high humidity may produce

undesirable changes in the film.

Unexposed Film

Store unexposed film in a refrigerator at 55°F (13°C) or

lower, or freezer at 0 to -10°F (-18 to -23°C), in the original

sealed container. If the film is stored in a refrigerator, remove

it about 2 hours before opening; if stored in a freezer, remove

it about 8 hours before opening. A sufficient warm-up time

is necessary to prevent moisture condensation on cold film --

otherwise, moisture spotting, ferrotyping, or sticking may

occur.

Exposed Film

Keep exposed film cool and dry. Process the film as soon as

possible after exposure to avoid undesirable changes in the

latent image. If it is necessary to hold exposed but

unprocessed film for several days (such as over a weekend),

it should be resealed and refrigerated at 40°F (4°C) or lower.

Before unsealing and processing exposed film that has been

held in cold storage, follow the warm-up procedures

described for unexposed film described above.

Developer

Resolving Power

(line pairs/mm)

rms Granularity

*

TOC 1.6:1 TOC 1000:1

885

641

Type A

50

40

38

125

125

94

26

26

42

Processed Film

For best keeping, store processed film in a dark, dust-free

area at 50 to 70°F (10 to 21°C) and 30 to 50 percent relative

humidity. Preferably, store negatives on the spool or in

individual KODAK PROFESSIONAL Sleeves. High relative

humidity promotes the growth of mold and causes

ferrotyping. Very low relative humidity causes excessive curl

and brittleness. Avoid storage temperatures over 80°F

(27°C).

PROCESSING

KODAK DOUBLE-X AEROGRAPHIC Film 2305 can be

processed in KODAK VERSAMAT Film Processor, Models

11 and 1140, with KODAK VERSAMAT 885 Chemicals,

KODAK VERSAMAT 641 Chemicals, or KODAK

VERSAMAT Chemicals, Type A.

Mechanized processing in roller-transport processors

offers the advantages of uniform treatment of all portions of

the roll, freedom from banding, and absence of significant

density variations from ends of the roll to the center. Refer to

the operator’s manual for the processor set-up information,

but in all cases, the fixer replenisher should be introduced

into tank No. 5 of the processor with a countercurrent flow

to tank No. 3, where it overflows to a collection or recovery

system.

General instructions for setting the machine dryer

temperature are included in these pages. However, the

temperature of the dryer may require some further

adjustment, depending upon the ambient temperature

conditions in the processing area. Usually it is best to set the

temperature approximately 3°F (2°C) above that required to

dry unexposed, processed film.

Chemicals

The following KODAK VERSAMAT Chemicals may be

used in both the Model 11 and Model 1140 VERSAMAT

Processors.

KODAK VERSAMAT 885 Developer Starter

KODAK VERSAMAT 885 Developer Replenisher

KODAK VERSAMAT 885 Fixer and Replenisher

KODAK VERSAMAT 641 Developer Starter

KODAK VERSAMAT 641 Developer Replenisher

KODAK VERSAMAT 641 Fixer and Replenisher

KODAK VERSAMAT Developer Starter, Type A

KODAK VERSAMAT Developer Replenisher, Type A

KODAK VERSAMAT Fixer and Replenisher, Type A

Notice: Observe precautionary information on product labels and on

the Material Safety Data Sheets.