10

3. Do not heat a part with a flame to free it for removal unless

the part being heated is already worn or damaged beyond

repair and no additional damage will occur to other parts.

In general, the hoist is designed to permit easy disassembly

and assembly. The use of heat or excessive force should

not be required.

4. Keep the work area as clean as practical, to prevent dirt and

other foreign matter from getting into bearings or other

moving parts.

5. When grasping a part in a vise, always use leather-covered

or copper-covered vise jaws to protect the surface of the

part and help prevent distortion. This is particularly true of

threaded members, machined surfaces and housings.

6. Do not remove any part which is press fit in or on a

subassembly unless the removal of that part is necessary for

repairs or replacement.

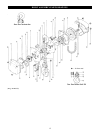

Disassembly

Brake Disc Replacement

1. Unscrew U-nuts (36). Remove wheel cover (35).

2. Remove hand chain (46) from hand wheel (31).

3. Remove cotter pin (34), unscrew pinion nut (33) and

remove washer (32).

4. Remove hand wheel (31) by holding the load chain (43)

and rotating hand wheel (31) counterclockwise until it can

be lifted off pinion shaft (13).

5. Remove brake cover (30) and brake disc A (27).

6. Remove ratchet gear (29) and brake disc B (28).

Cleaning, Inspection and Repair

Use the following procedures to clean and inspect the

components of the hoist.

Cleaning

Clean all hoist component parts in an acid free solvent (except

for the brake disc). The use of a stiff bristle brush will facilitate

the removal of accumulated dirt and sediments on the gears and

frames. Dry each part using low pressure, filtered compressed air.

Inspection

All disassembled parts should be inspected to determine their

fitness for continued use. Pay particular attention to the

following:

1. Inspect all gears for worn, cracked, or broken teeth.

2. Inspect shafts for ridges caused by wear. If ridges caused

by wear are apparent on shafts, replace the shaft.

3. Inspect all threaded items and replace those having

damaged threads.

4. Measure the thickness of the brake discs. If brake discs do

not have uniform thickness or are less than 5/64 in. (2 mm)

thick replace brake discs.

Repair

Actual repairs are limited to the removal of small burrs and

other minor surface imperfections from gears and shafts. Use a

fine stone or emery cloth for this work.

1. Worn or damaged parts must be replaced. Refer to the

applicable parts listing for specific replacement parts

information.

2. Inspect all remaining parts for evidence of damage.

Replace or repair any part which is in questionable

condition. The cost of the part is often minor in comparison

with the cost of redoing the job.

3. Smooth out all nicks, burrs, or galled spots on shafts,

bores, pins, and bushings.

4. Examine all gear teeth carefully, and remove nicks and

burrs.

5. Polish the edges of all shaft shoulders to remove small

nicks which may have been caused during handling.

6. Remove all nicks and burrs caused by lockwashers.

Assembly

CAUTION

• The brake will not operate properly if there is too much oil

on the brake discs (27 and 28). Excessive oil or grease on

brake components could cause the load to slip.

1. Dip replacement brake discs (27 and 28) in ISO VG32

hydraulic oil or SAE 10 oil for two seconds. Wipe off

excess oil.

2. Place brake disc B (28) over hub (26). Brake disc B (28)

has a smaller outside diameter than brake disc A (27).

3. Install ratchet gear (29) on hub (26) so recessed face fits

over brake disc B. Teeth of ratchet gear (29) must engage

pawl (24). Ratchet gear (29) should not rotate

counterclockwise and should “click” when rotating

clockwise.

4. Place brake disc A (27) on ratchet gear (29).

5. Place brake cover (30) over stay bolts on side plate 1

assembly (1).

6. With brake surface of handwheel (31) towards the brake

disc A (27), place handwheel (31) on pinion shaft (13).

Rotate handwheel (31) clockwise until clicking occurs.

Hold load chain (43) if necessary.

7. Place washer (32) over pinion (13). Install pinion nut (33)

and cotter pin (34). Refer to “Brake Adjustment.”

8. Install hand chain (42) on handwheel (31). Make sure hand

chain (42) is seated properly.

9. Place wheel cover (35) over stay bolts. Install U-nuts (36).

Gears (14)

1/2, 1 and 2 ton units do not use gears with a circle.

On 1-1/2, 3 and 5 ton units, each hoist body must have one gear

without a “circle” and one gear with a “circle”. Refer to Dwg.

MHP0044.

(Dwg. MHP0044)

NOTICE

• The 1/2 ton hoist has a center pinion gear with only 5 teeth.