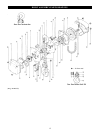

9

4. Run the new chain to its anchor point. On smaller units, use

the hand chain (42) to move the load chain. On larger units,

load chain (43) installation can be speeded up by

unscrewing U-nuts (36), removing gear cover (17), support

plate (16) and taking out 2nd gear set (14). With the 2nd

gear set (14) removed, the load chain (43) can be pulled by

hand through the hoist body and hook blocks. Reinstall 2nd

gear set, support plate (16), gear cover (17) and U-nuts

(36).

5. Remove “C” link and old chain.

6. On 1/2 to 2 ton hoists, anchor load chain (47) to bottom

hook block. On 3 and 5 ton units, anchor load chain to top

hook frame. To connect, install chain bolt (39) and U-nut

(40).

For information on connecting unloaded end of load chain refer

to “Attaching End of Load Chain” section.

7. Check for the following:

a. The load chain did not become twisted, when reeving

the load chain (43) between the idler sheave on the

bottom hook assembly and the hoist load sheave.

Refer to Dwg. MHP0020.

b. Make sure load chain (43) is reeved between load

sheave (6) and chain guides (7).

(Dwg. MHP0020)

(Dwg. MHP0043)

Attaching End of Load Chain

Refer to Dwg. MHP0410

1. Push end pin (20) “in”, towards end spring (19) and

remove end anchor A (21).

2. Slide end link of load chain (43) on end anchor A (21)

shaft.

3. Insert end anchor A (21) shaft into end anchor B (22) guide

hole.

4. Reinstall end anchor A (21) on end pin (20). Depress and

align end pin (20) in side plate 1 (1) hole. When released

end pin (20) should spring into position and slide into hole

in side plate 1 (1).

Ensure load chain (43) is not twisted, kinked or “capsized.”

Refer to Dwg. MHP0043.

20

21

22

19

(Dwg. MHP0410)

Brake Adjustment

1. Unscrew nuts (36) and remove wheel cover (35) so that

handwheel (31) is exposed.

2. Remove cotter pin (34) and tighten pinion nut (33)

(Clockwise). Hold load chain (47), if necessary, to keep

pinion shaft (13) from rotating.

3. Back off pinion nut (33) approximately 1/8th of a turn

(Counterclockwise) and reinsert cotter pin (34).

4. Remove all slack from the chain.

5. Pull on the hand chain to lift the load approximately 2 feet

(0.5 m) off the floor.

General Disassembly

The following instructions provide the necessary information to

disassemble, inspect, repair, and assemble the hoist. Parts

drawings of the hoist assembly are provided in the Parts Section.

If a hoist is being completely disassembled for any reason,

follow the order of the topics as they are presented.

It is recommended that all maintenance work on the hoist be

performed on a bench.

In the process of disassembling the hoist, observe the following:

1. Never disassemble the hoist any further than is necessary to

accomplish the needed repair. A good part can be damaged

during the course of disassembly.

2. Never use excessive force when removing parts. Tapping

gently around the perimeter of a cover or housing with a

soft hammer, for example, is sufficient to break the seal.