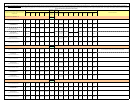

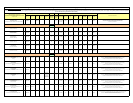

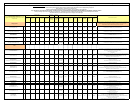

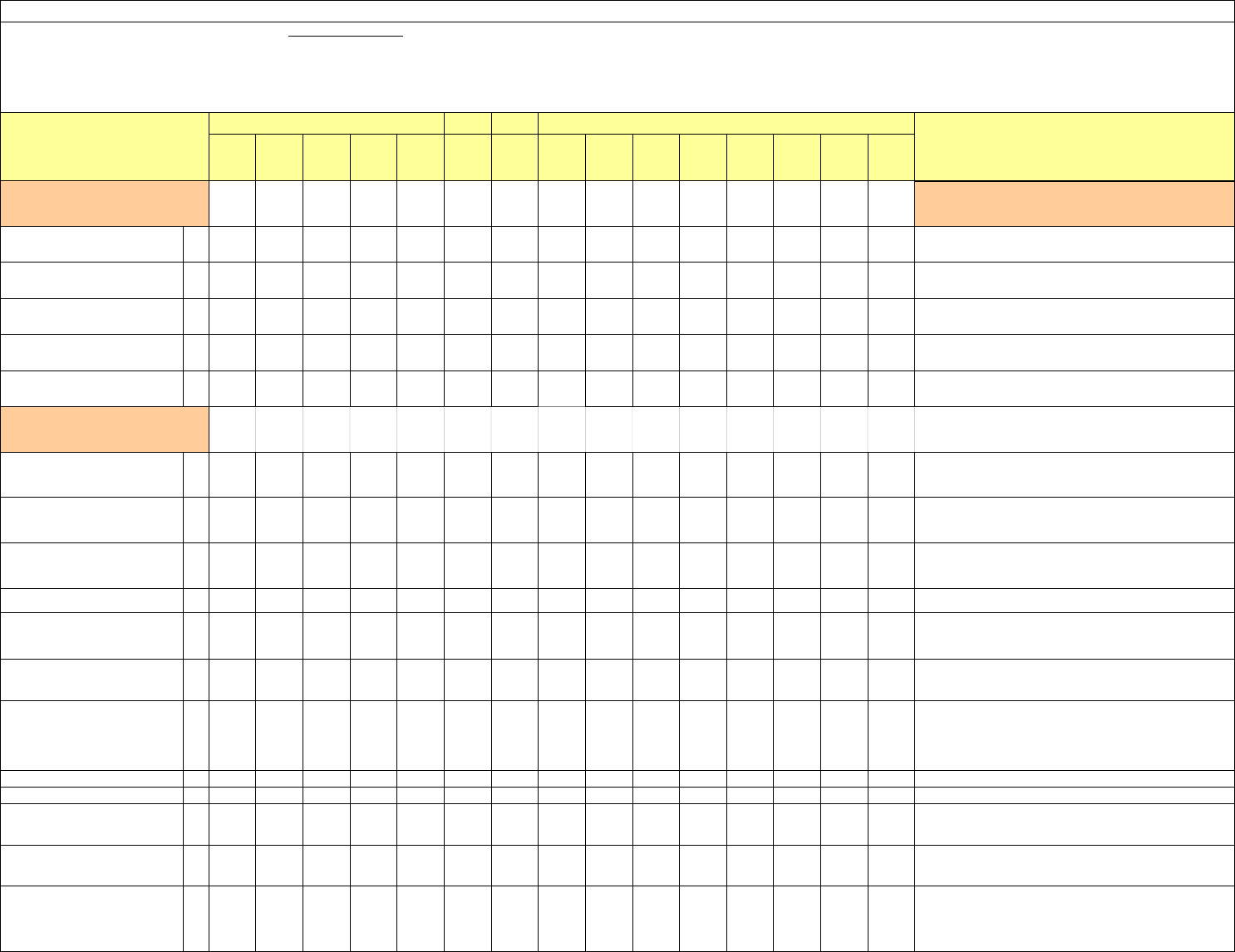

Basis Weight

(lb)

Grammage

Weight (gsm)

Xerox iGen4 90/110 Digital Production Press, Xerox iGen4 220 Perfecting Press, and iGen4 Xerox Automated Packaging Solution configuration North America Custom Media List February, 2011

The Xerox CUSTOM Media List contains custom media that has been tested on the Xerox iGen4 90/110 Digital Production Press for image quality and performance.

Custom media on this list are digitally optimized, designed and manufactured for performance in Xerox digital printing equipment.

Best Practices for Operation are outlined below.

Customers should validate the Best Practices for Operation are acceptable for their application.

*Any alterations to the product's basic design, including sheet size, must be tested and approved by the Xerox Media & Compatibles Technology Center.*

When purchasing a particular media product for the first time, customers are advised to purchase small quantities to insure that expectations are met.

CUSTOM media may be ordered through the Xerox Supply Account Manager.

Stock Library Name (Full Media Name)

It is imperative to utilize the bolded, abbreviated stock name for easy

migration to future enhancements to the stock library and media

management tools.

Base Size Tested

Best Practices for Operation

8.5 x 11 8.5 x 14 17 x 11 18 x 12 Other Size

Weight of 500

sheets of the

paper specific

to grade type

Weight of the

paper in grams

per square

meter

Sides Coated Coating Type Cleanup FinishType Sequence Color

Thickness

(microns)

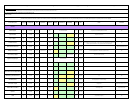

For best performance it is recommended that these media be stored and run at a relative humidity between 50-

55% and temperature between 68 - 73 F.

A

ssure packaging board has adequately acclimated to the conditions in which it is to be printed.

Requires setup to the Xerox Automated Packaging Solution Configuration.

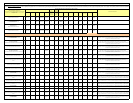

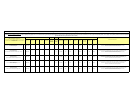

XeroxFoldingBoard14pt

(Xerox Folding Board 14 pt)

X X 14.33 x 22.5 256

C1S (Coated

One Side)

High-gloss Plain 0 White 356 Yes Smooth

Recommend Simplex only.

This media may react adversely in dry environmental conditions.

XeroxDCtd1Side15pt

(Xerox Digital Coated C1S Board 15 pt.)

14.33 x 22.5 270

C1S (Coated

One Side)

Gloss Plain 0 White 379 Yes Smooth

Recommend Simplex only.

This media may react adversely in dry environmental conditions.

XeroxLasoBoard18pt

(Xerox LasoBoard 18 pt.)

X 14.33 x 22.5 335

C1S (Coated

One Side)

Gloss Plain 0 White 462 Yes Smooth

Recommend Simplex only.

This media may react adversely in dry environmental conditions.

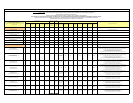

XeroxFoldingBoard18pt

(Xerox Folding Board 18 pt.)

X X 350

C1S (Coated

One Side)

High-gloss Plain 0 White 462 Yes Smooth

Recommend Simplex only.

This media may react adversely in dry environmental conditions.

XeroxCCNB18pt

(Xerox Clay Coated News Back 18 pt.)

X 350

C1S (Coated

One Side)

Gloss Plain 0 White 472 Yes Smooth

Recommend Simplex only.

This media may react adversely in dry environmental conditions.

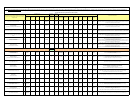

XeroxProColorPBTran17

(Xerox Production Color Paper Backed Transparency 11 x 17)

X 180

C1S (Coated

One Side)

Gloss Transparency 0 Clear 187 No Smooth

This media may have a mottled appearance due to poor paper formation (image density and gloss).

Simplex only recommended

Static build up may affect media runnability and/or stacking.

Output to top tray only. 80 sheets.

Do not invert.

XeroxDuraPaper 12pt

(Xerox DuraPaper 12 pt)

X 220 Uncoated N/A Plain 0 White 305 No Regular

If image permanence adjustment is required, refer to ADJ 1-Pressure Roll Contact Arc Adjustment procedure in

the latest Customer Maintenance Manual.

Static build up may affect media runnability and/or stacking.

Auto Duplex side to side registration may not be within 1.5mm due to composition of the media.

TAB Blade may need to be cleaned during run.

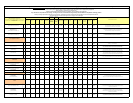

XeroxVinWinDecalFC

(Xerox Vinyl Window Decal Frosty Clear Stock #344)

X X X 220

C1S (Coated

One Side)

Gloss Custom 0 White 258 No Smooth

Simplex only recommended

Static build up may affect media runnability and/or stacking.

XeroxVinWinDecalW

(Xerox Vinyl Window Decal White Stock #309)

X X X 220

C1S (Coated

One Side)

Gloss Custom 0 White 258 No Smooth

Simplex only recommended

Static build up may affect media runnability and/or stacking.

XeroxDuraPaper 14pt

(Xerox DuraPaper 14 pt)

X 247 Uncoated N/A Plain 0 White 356 No Regular

If image permanence adjustment is required, refer to ADJ 1-Pressure Roll Contact Arc Adjustment procedure in

the latest Customer Maintenance Manual.

Static build up may affect media runnability and/or stacking.

Auto Duplex side to side registration may not be within 1.5mm due to composition of the media.

TAB Blade may need to be cleaned during run.

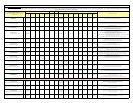

XeroxPolyPaper 8mil

(Xerox Polyester Paper 8 mil)

X X 14.33 x 20.5 258

C2S (Coated

Two Sides)

Gloss Plain 0 White 195 No Smooth

Static build up may affect media runnability and/or stacking.

Some side to side color difference may be seen if auto duplexing.

Some skew may be seen if auto duplexing.

XeroxVinWinClingFC

(Xerox Vinyl Window Cling Frosty Clear Stock #405)

X 260

C1S (Coated

One Side)

Gloss Custom 0 White 429 No Smooth

Simplex only recommended

Static build up may affect media runnability and/or stacking.

XeroxVinWinClingW

(Xerox Vinyl Window Cling White Stock #318)

X 260

C1S (Coated

One Side)

Gloss Custom 0 White 429 No Smooth

Simplex only recommended

Static build up may affect media runnability and/or stacking.

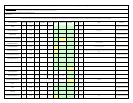

XeroxDuraKote

(Xerox DuraKote 10 pt)

X 300

C2S (Coated

Two Sides)

Gloss Plain 0 White 249 Yes Smooth Static build up may affect media runnability and/or stacking.

XeroxPolyPaper 11mil

(Xerox Polyester Paper 11 mil)

X 14.33 x 20.5 350

C2S (Coated

Two Sides)

Gloss Plain 0 White 270 No Smooth

Static build up may affect media runnability and/or stacking.

Some side to side color difference may be seen if auto duplexing.

Some skew may be seen if auto duplexing.

Feed from a lower tray.

High static may impact inline finishing.

XeroxPolyPaper 14mil

(Xerox Polyester Paper 14 mil)

X 14.33 x 20.5 350

C2S (Coated

Two Sides)

Gloss Plain 0 White 350 No Smooth

Static build up may affect media runnability and/or stacking.

Some side to side color difference may be seen if auto duplexing.

Some skew may be seen if auto duplexing.

Feed from a lower tray.

High static may impact inline finishing.

XeroxUltraMagnet

(Xerox Ultra Magnet)

X 350

C1S (Coated

One Side)

Gloss Plain 0 White 439 No Smooth

Simplex only recommended

Static build up may affect media runnability and/or stacking.

Feed from a lower tray only.

To enable running toggle NVM 12509 (Lower Tray Multifeed Detected FLTByp).

To enable running Service must set NVM 6876 (LE Late tat TAR sensor Jam Offset) to maximum value.

Output to top tray or bypass tray, if enabled.

Skew up to 10mm may be seen.

For best image quality do not image within 40 mm of lead or trail edges of the media.

Packaging Board

Other