Aspherical Lenses

Ordinary spherical elementshave an

inherent flaw in thatthe point of focus

for the lens center does not match that

of the lens periphery. Spherical

aberrations of large-aperture lenses and

distortion by ultra-wide-angle lenses

cannot be resolved with spherical

elements alone. The Aspherical lens

element was therefore developed. The

curvature of the lens element is calculated

and shaped to achieve the ideal single

point of focus. The result ishigh contrast

with minimal flare even with a large-

aperture lens. Distortion can also be

effectively corrected in ultra-wide-angle

lenses. Canon started to develop

manufacturing technology for Aspherical

elements early on. We eventually

succeeded in establishing a mass-

production grinding and polishing

processwith a polishing precision of

5/10,000 mm. In 1971, Canon marketed

the FD 55mm f/1.2AL lens, the world’s

first large-aperture Asphericallens for

SLRs. Thiswas followed by many other

Canon lensesincorporating Aspherical

elements and they were well received.

Also, Canon developed mass-production

technology for glass-molded aspherical

elements and replicated Aspherical

lenses. The former was produced by an

ultra-high-precision aspherical lens-

molding machine which shaped the glass

directly. For the latter, the Aspherical

surface was formed by ultraviolet-

hardened resin film applied on a spherical

element. Canon hasdeveloped

numerous compact-size lenses, taking

full advantage of Asphericalelements

to attain high image quality.

Ultrasonic Motors (USM)

The Ultrasonic Motor (USM) in Canon

EF lenses isthe world’s first lens-based

motor. Based on a totally new

technology, the motor spins by ultrasonic

oscillation energy. The USM is quiet

and quick. It has made EFlenses almost

noiseless and autofocusing fast,

precise, and practical. The direct-drive

construction is very simple, with no gear

train. This makes it durable and efficient.

It also consumeslittle power. Two types

of USM are used: Ring-type USM and

Micro USM. The former type is found in

large-aperture and super telephoto

lenses, while the latter is used in more

compact lenses. Using the optimum

type of USM in the lensresults in

maximum efficiency and effectiveness.

35

Technology Where It Counts

Canon’s innovations put your images on film quickly, quietly, and

easily with outstanding results.

34

MRing-type USM

Micro USM

Spherical aberration ofspherical lens.

Convergence of parallel lightrays by

an Aspherical lens.

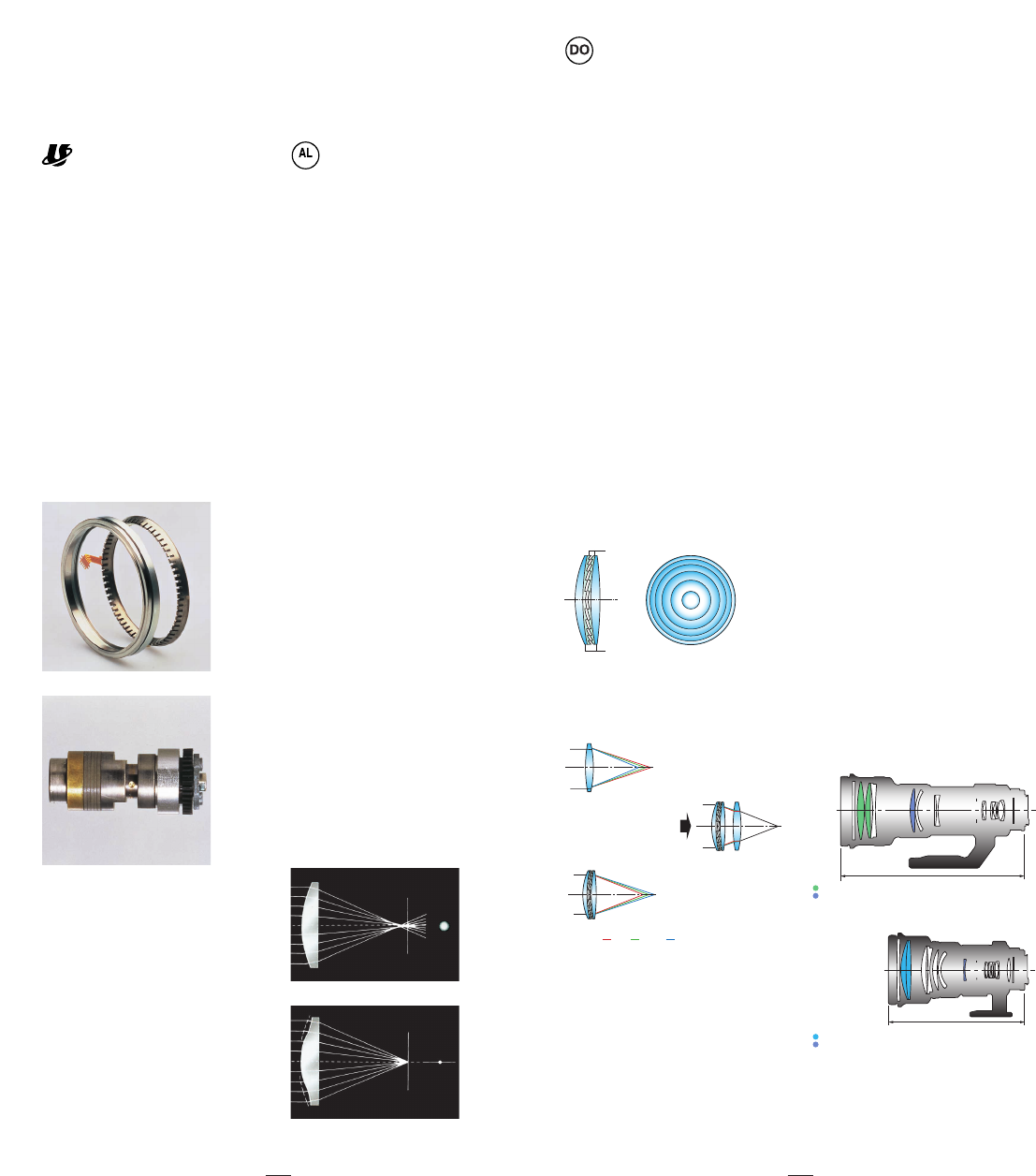

Diffractive Optics

Another world’s first in camera lens

optical design, Canon introduced new

technology in order to build a super

telephoto that complements itslatest

compact film and digital SLR cameras.

Thiscutting-edge technology employs

diffractive optical elementsthat use the

principle of diffraction to change the

direction of the lightwave’s path. This

revolutionary element has Aspherical

characteristics, which help define

superior maximum aperture image

quality, as well as optical qualities

superior to UD-glassto totally correct

color fringing. The Multi-Layer Diffractive

Optical Elements exhibit outstanding

ability to correct chromatic aberrations

(color defects), and are especially effective

in super telephoto lens design where

these specific types of optical defects

are most likelyto happen. You can see

how well the technology works in your

own pictures byexamining the straight

edges of a subjectin your picture. You

will see a crisp, clear edge without

the

telltale, prismatic color fringing that is visible

with imagesshot using inferior optics.

Glasslens elements refract, or bend

lightwaves, as they pass through to

form an image. That’s simply the

naturallyoccurring physicsof light. We

use multiple elements and special glass

to help keep the waves focused like a

pinpoint instead of spreading them into

the rainbow of color seen when light

passes through a glassprism. To

diffract a lightwave means

that the raygoes through a change in

direction before passing through the lens.

The change in direction is caused by a

diffraction grating—very fine parallel

grooves or slits on the surface. Canon

found that using a concentric diffraction

grating that getssmaller toward the

edges—some asfine as tenths of a

micrometer—solved many of one

inherent physical limitations of camera

optics. The design also makesit

possible to obtain the same effect as an

Aspherical lens. And taking the

technology a step beyond, we actually

use two single-layer diffractive optical

elements whose diffraction gratingsare

bonded together face-to-face. Since

longer wavelengths form an image closer

to the lens due to the large diffractive

angle, and shorter wavelengths form an

image farther from the lens due to the

smaller diffractive angle, putting the DO

elements with conventional glassoptics

actually cancels outeach other’s

chromatic aberrations and isexceptionally

effective in correcting this optical defect.

The diffraction that occurs with Canon’s

Multi-Layer Diffractive optical elements

actually corrects the optical system’s

chromatic aberrations and improves the

image formation performance.

The net resultof Canon’sDO technology

is a lens design with reduced size and

weight while offering higher image quality

than a comparable focal length lens that

incorporates conventional glass optical

elements. It means a new generation of

high-performance lenses thatcomplement

the more compactdesigns of our latest

SLR film and digital cameras.

Refractive Optical Element

Chromatic aberration

canceled out

Refractive Optical

Element and Multi-

Layer Diffractive

Optical Element

Combined

Chromatic aberrations

reversed from

that of a

refractive optical element

Image formation in the red, green,

and blue wavelength order

Red

Green Blue

Multi-Layer Diffractive

Optical Element

Image formation in

the blue, green, and

red wavelength order

Chromatic aberrations

Diffractive

grating

Glass

lenses

Cross section Front view

Correction of Chromatic Aberration bythe

Multi-Layer Diffractive OpticalElement

Multi-Layer Diffractive OpticalElement Construction

400mm f/4 Lens Designed with a Refractive

Optical Element Only

400mm f/4 DO IS USM

(Incorporates Multi-Layer Diffractive Optical Element)

UD element

317mm Weight: 3,000g

Fluorite

Multi-layer diffractive optical element

232.7mm Weight: 2,080g

(Including removable

tri

p

od collar)

Fluorite

Lens Downsizing with the Multi-Layer Diffractive

Optical Element

Note: If a very bright spotlightlike a mercury lamp

is photographed with a DO lens, a ring of light may

occasionally appear around the light source, due to

the imaging characteristicsofthe Multi-Layer

Diffractive Optical Element.