D-483

Processor Setup Specifications

Concentrate developer - Kodak COM Professional Developer and Replenisher DRC

(Typical continuous-strand deep-tank processor)

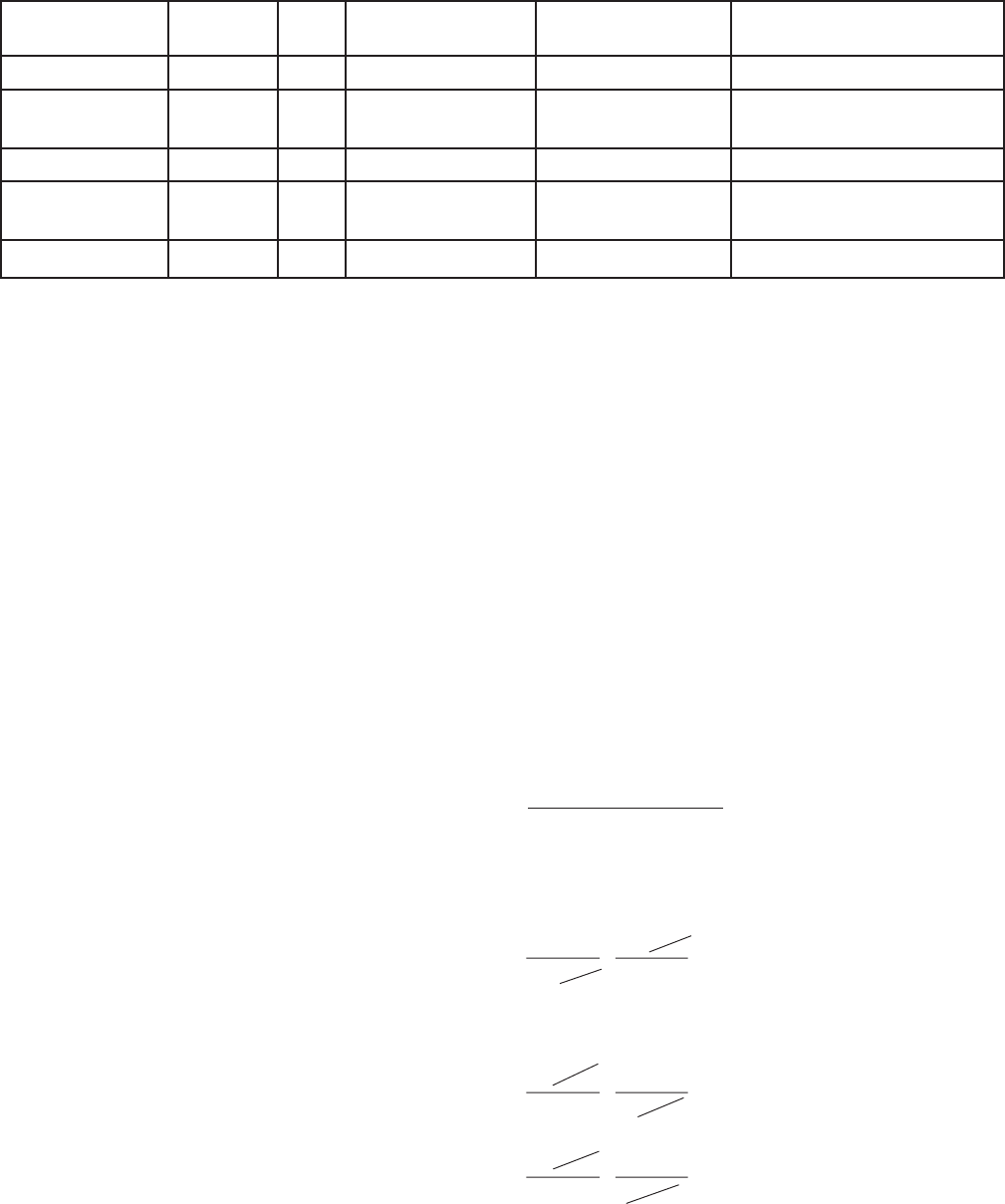

Processing Solutions Time Temperature Working Strength Replenishment (ml/ft.)

Step (Dilutions) (sec.) Specific Gravity 16 mm 35 mm 105 mm

Developer DRC

1

1:3 35 9495°F (3435°C) 1.080 to 1.090 1 - 3 3 - 5 7.5 - 10*

Rinse - 17.5 9095°F (3235°C) - Flow rate per processor

manufacturer recommendation

Fixer

2

1:5 35 9095°F (3235°C) 1.040 to 1.063 0.65 1.35 4

Wash - 35 9095°F (3235°C) - Flow rate per processor

manufacturer recommendation

Dry - - 160°F max. (71°C) - - - -

*Actual replenishment rate is determined by consideration of the rate that achieves a stable D-max with average quantity of

film processed.

1

Kodak COM Professional Developer and Replenisher DRC

2

Kodak Microfilm Fixer and Replenisher

Development Time and Transport Speed

Development/transport times should be set by

timing film speed (splice point) top of rack, roller-

to-roller while running in the processor. Transport

speeds are based on actual dwell times and

photographic aims, and are determined by timing

film speed, top of rack, entrance roller to exit

roller while running in the processor.

Replenishment Rates

Once development time and transport rates

are set to acquire desired photographic aims,

replenishment rate settings are determined by

multiplying the transport speed by the required

replenishment rates for the appropriate film width

being used. Replenishment may be reduced if

significant quantities of leader are used. For

instance, with Kodak COM Professional

Developer and Replenisher DRC, practical

experience indicates rates as low as 7.5 mL/ft

of 105 mm film are adequate in deep tank

processors. The use of control charts such

as Kodak Publication A-1631 is recommended

for monitoring control.

Transport Replenishment/ Replenishment

speed x ft of film = rate

(ft/min) (mL/Lft) (mL/min*)

*1 mL/min = 1 cc/min

These are starting-point recommendations

for deep-tank processors. Shallow-tank and

medium-tank processors, or variable operating

conditions in all processors, may require

replenishment rate adjustments to maintain

process activity levels.

Example

Processor: Allen F-10R

Type of film: 105 mm COM DR

Dwell: 32 seconds

Developer Film Path: 6.5 feet

See table above for:

Replenishment (Dev): 7.5

Replenishment (Fix): 4

Calculated transport speed:

6.5 feet x 60 sec

32 sec min

= 12 ft / min

12 feet x 7.5 mL

min feet

= 90 mL / min*

(developer replenishment)

Replenishment results:

12 feet x 4 mL

min feet

= 48 mL / min*

(fixer replenishment)