RECIPROCITY

No filter corrections or exposure

adjustments for exposure times from

1/1000 of a second to 1/10 second. In the

1-second range, increase exposure 2/3

stop and use a KODAK Color

Compensating Filter CC 10R. In the 10-

second range, increase exposure 1 stop

and use a KODAK Color Compensating

Filter CC 10R.

IDENTIFICATION

After processing, the Kodak internal

product code symbol (EH), product code

numbers 5218 (35 mm) or 7218 (16 mm),

emulsion and roll number identification,

and EASTMAN KEYKODE Numbers are

visible along the length of the film.

GRAIN

The perception of graininess of any film

depends on scene content, complexity,

color, and density. In KODAK VISION2

500T Color Negative Film 5218 / 7218,

the measured granularity is

exceptionally low.

SHARPNESS

The perceived sharpness of any film

depends on various components of the

motion picture production system.

Camera and projector lenses, film print-

ers,and other factors play a role, but the

specific sharpness of a film can be

measured and charted in the Modulation

Transfer Curve.

COLOR BALANCE

This film is balanced for exposure with

tungsten illumination (3200 K). You can

also expose it with tungsten lamps that

have slightly higher or lower color

temperatures (± 150 K) without

correction filters, since final color

balancing can be done in printing. For

other light sources, use the correction

filters in the table below.

POST-PRODUCTION INFORMATION

When you transfer this film directly to

video, set up the telecine using negative

Telecine Analysis Film (TAF).

BASE

Acetate safety base with rem-jet

backing.

DARKROOM RECOMMENDATIONS

Do not use a safelight. Handle

unprocessed film in total darkness.

PROCESSING

ECN-2

STORAGE

Store unexposed film at 13°C (55°F) or

lower. For storage of unexposed film

longer than 6 months, store at –18°C

(0°F). Process film promptly.

EXPOSURE INDEX

Tungsten (3200 K)—500; Daylight—320

(with KODAK WRATTEN Gelatin Filter

No. 85)

LABORATORY AIM DENSITY

Time negative originals relative to

Laboratory Aim Density (LAD)

Control Film supplied by

Eastman Kodak Company.

SENSITOMETRIC CURVES ➤

"0" on the x-axis represents normal exposure

of an 18-percent gray card in the red, green, and

blue layers of this film. A white card is

2 1/3 stops higher than normal exposure,

and there are at least 2 1/2 stops above that

for capturing specular highlight detail.

A 3-percent black card is 2 2/3 stops below

normal exposure. There are at least 2 1/2

stops of latitude below that for capturing

shadow detail.

DIFFUSE RMS GRANULARITY CURVES ➤

To find the rms granularity value for a given

density, find the density on the left vertical scale

and follow horizontally to the sensitometric curve

and then go vertically (up or down) to the

granularity curve. At that point, follow

horizontally to the Granularity Sigma D scale

on the right. Read the number and multiply

by 1000 for the rms value.

SPECTRAL-SENSITIVITY CURVES ➤

These curves depict the sensitivity of this film to

the spectrum of light. They are useful for

determining, modifying, and optimizing exposure

for blue- and green-screen

special-effects work.

SPECTRAL DYE-DENSITY CURVES ➤

These curves depict the spectral absorptions of

the dyes formed when the film is processed. They

are useful for adjusting or optimizing any device

that scans or prints the film.

NOTE: Cyan, Magenta, and Yellow Dye

Curves are peak-normalized.

Spectral Sensitivity Curve Key

Spectral Dye Density Curve Key

Sensitivity of the yellow dye

forming layer

Sensitivity of the magenta dye

forming layer

Sensitivity of the cyan dye

forming layer

Midscale Neutral

Cyan Dye

Magenta Dye

Yellow Dye

Minimum Density

LOG EXPOSURE (lux-seconds)

3.0

2.0

1.0

DENSITY

0.0

CAMERA STOPS

-10 -8 -6 -4 -2 0 2 4 6

-4 -2 -1-3.2 -0.2

RESPONSE (%)

SPATIAL FREQUENCY (c/mm)

1

1

10

100

1000

10 100 1000

3.0

.004

RELATIVE LOG H (lux-seconds)

1.00.0

0.0

DENSITY

1.0

3.0

.001

.010

.002

.030

.100

GRANULARITY SIGMA D

0.2

0.6

1.4

1.8

2.2

2.6

4.02.0

4.0

3.0

2.0

1.0

*

0.0

LOG SENSITIVITY

2

WAVELENGTH (nm)

to produce specified density

*Sensitivity = reciprocal of exposure (erg/cm ) required

250 300 350 400 450 500 550 600 650 750700

1.8

1.4

1.0

0.6

0.2

700 750 800400 450 500 550

-2.0

300 350

WAVELENGTH (nm)

600 650

DIFFUSE SPECTRAL DENSITY

Tungsten (3000 K) WRATTEN Gelatin No. 82B 320

Tungsten (3200 K) None 500

Tungsten Photoflood (3400 K) None 500

Daylight (5500 K) WRATTEN Gelatin No. 85 320

White-Flame Arcs WRATTEN Gelatin No. 85B 200

Yellow-Flame Arcs Color Compensating 20Y 320

OPTIMA 32 None 500

VITALITE WRATTEN Gelatin No. 85 320

Fluorescent, Cool White† WRATTEN Gelatin No. 85 +10M 200

Fluorescent, Deluxe Cool White† WRATTEN Gelatin No. 85C +10R 320

Metal Halide H.M.I. WRATTEN Gelatin No. 85 320

*These are approximate corrections only. Make final corrections during printing.

†These are starting-point recommendations for trial exposures. When you don’t know the type of fluorescent lamp,

use a KODAK Color Compensating Filter CC40R with an exposure index (EI) of 250.

LIGHT SOURCE KODAK FILTERS ON CAMERA* EXPOSURE INDEX

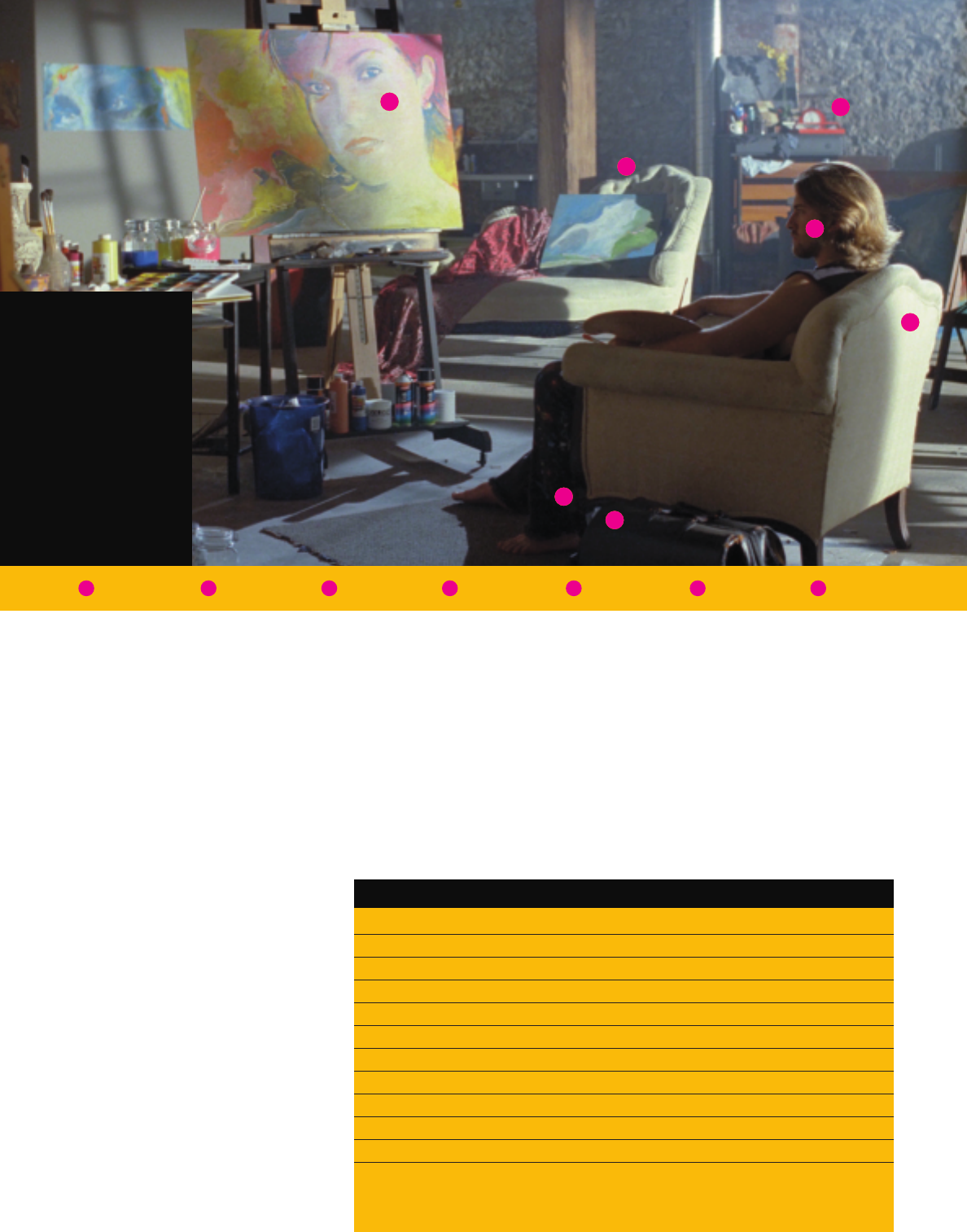

Original Negative

E

XPOSURE DATA

Lens: 32 mm ZEISS Ultra Prime

Lens

Filter: None

Aperture: T 2.8

Incident Light Levels

(Tungsten 2950K):

Key = T 2.8 (20 fc)

Fill = T 1.3 (4 fc)

Backlight = T 5.0 (64 fc)

Stop notations listed on the photo

are reflected-light readings.

Note: There is a small amount of

atmospheric smoke in the scene.

1

-4 Stops -3 Stops -1.3 Stops Normal +1.4 Stops +3.5 Stops +4.2 Stops

4

5 6

7

2

3

6

4

5

3

7

1

2

Note: Sensitometric and Diffuse RMS Granularity curves are produced on different equipment.

A slight variation in curve shape may be noticed.

MODULATION-TRANSFER CURVES➤

This graph shows a measure of the visual

sharpness of this film. The x-axis, “Spatial

Frequency,” refers to the number of sine waves

per millimetre that can be resolved. The y-axis,

“Response,” corresponds to film sharpness. The

longer and flatter the line, the more sine waves

per millimetre that can be resolved with a high

degree of sharpness—and the sharper the film.

61966-Broch 10/6/05 7:51 PM Page 2