16 of 22 Revision Nov 2008

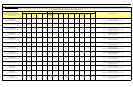

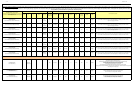

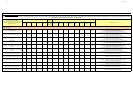

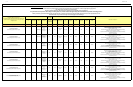

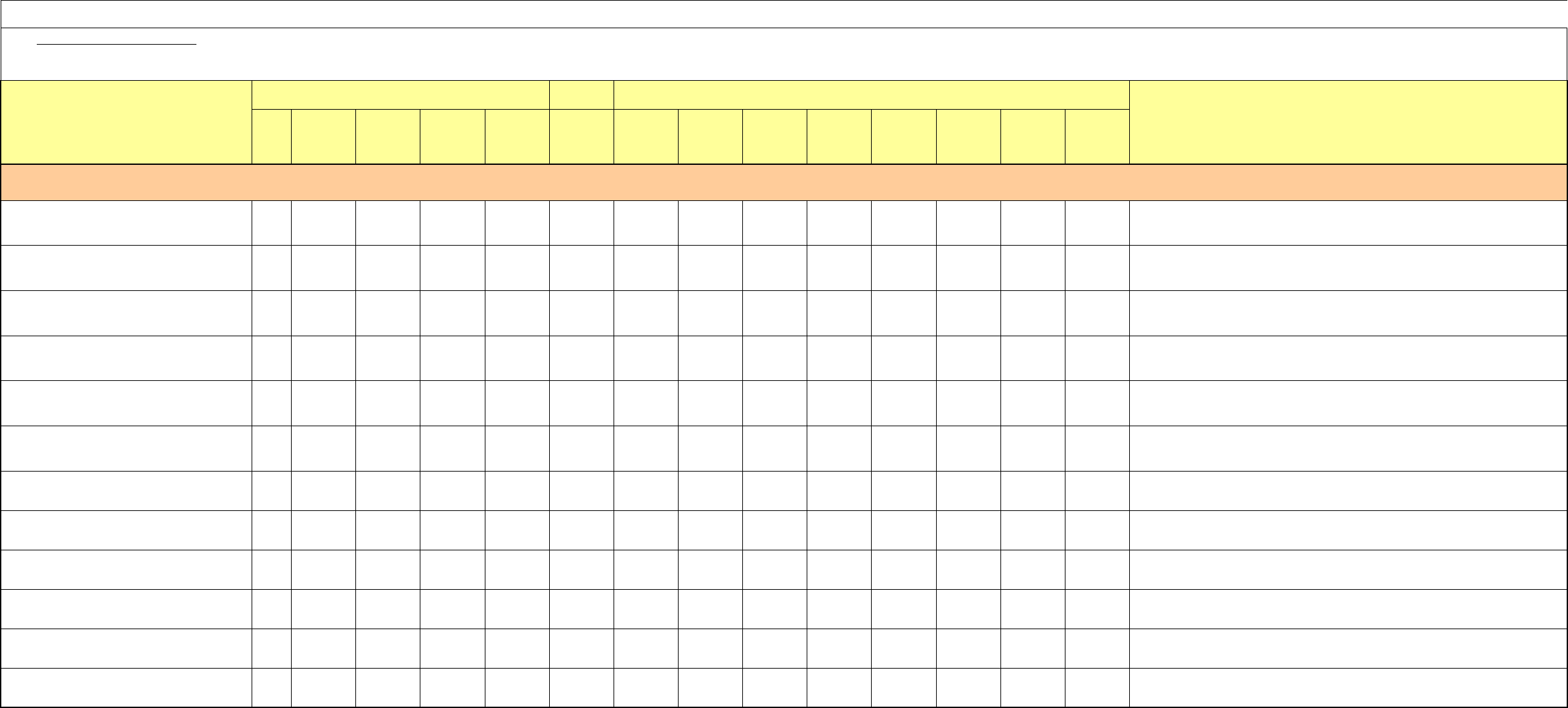

Grammage

Weight (gsm)

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen3 90/100/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally optimized, designed

and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media. Xerox paper and specialty media are tested

and qualified by Xerox laboratories to guarantee consistent quality.

iGen3 Digital Production Press Guaranteed Media List - Europe - April 2010

Best Practices for Operation

Weight of the

paper in grams

per square meter

Sides Coated Coating Type Type Sequence Color

Thickness

(microns)

Cleanup FinishOther Size

Stock Library Name (Full Media Name)

It is imperative to utilize the bolded, abbreviated stock name for

easy migration to future enhancements to the stock library and

media management tools.

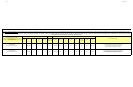

Standard cut sizes

Drilled

A4 A3 SRA3

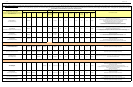

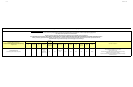

Specialties- Carbonless

XeroxCarb2SWP

(Xerox Carbonless, 2 part, Straight PreCollated, White and Pink)

003R99107 80 Uncoated N/A Ordered 2 White 110 Yes Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended.

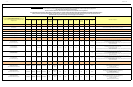

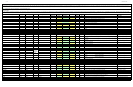

XeroxCarb2SWY

(Xerox Carbonless, 2 part, Straight PreCollated, White and Yellow)

003R99105 80 Uncoated N/A Ordered 2 White 110 Yes Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended.

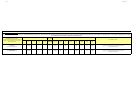

XeroxCarb3RPYW

(Xerox Carbonless, 3 part, Reverse PreCollated, Pink, Yelllow and

White)

003R99109 80 Uncoated N/A Ordered 3 White 110 No Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended.

XeroxCarb3SWYP

(Xerox Carbonless, 3 Part, Straight PreCollated, White, Yellow and

Pink)

003R99108 80 Uncoated N/A Ordered 3 White 110 No Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended.

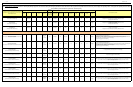

XeroxCarb4RGPYW

(Xerox Carbonless, 4 part, Reverse PreCollated, Green, Pink, Yellow

and White)

003R99112 80 Uncoated N/A Ordered 4 White 110 No Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended.

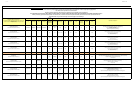

XeroxCarb4SWYPB

(Xerox Carbonless, 4 part, Straight PreCollated, White, Yellow,Pink

and Blue)

003R99111 80 Uncoated N/A Ordered 4 White 110 No Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended.

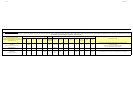

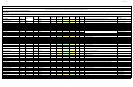

XeroxCarbCBSingleW

(Xerox Carbonless, Coated Back, Singles, White)

003R99069 80 Uncoated N/A Plain White 110 No Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

XeroxCarbCFBSingleW

(Xerox Carbonless, Coated Front and Back, Singles, White)

003R99070 80 Uncoated N/A Plain White 110 No Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

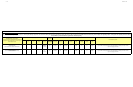

XeroxCarbCFBSingleY

(Xerox Carbonless, Coated Front and Back, Singles , Yellow)

003R99071 80 Uncoated N/A Plain Yellow 112 No Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

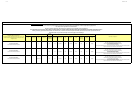

XeroxCarbCFSingleP

(Xerox Carbonless, Coated Front, Single, Pink)

003R99077 80 Uncoated N/A Plain Pink 107 No Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

XeroxCarbCFSingleW

(Xerox Carbonless, Coated Front, Singles, White)

003R99075 80 Uncoated N/A Plain White 110 No Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

XeroxCarbCFsingleY

(Xerox Carbonless, Coated Front, Singles, Yellow)

003R99076 80 Uncoated N/A Plain Yellow 112 No Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.