INON D-180 Manual

Version 1. October 4, 2003

Copyright 2002, 2003 by INON America, Inc. All rights reserved.

8

First, inspect the O-ring as it is seated in the groove. If any of the following are evident, there is a

high chance that the strobe will flood if placed in water. Be very careful about checking these

points:

If hair, sand, lint or other debris is attached to the O-ring

Remove O-ring and wipe-off the debris.

If the O-ring is cut or cracked

The O-ring must be removed and replaced with a new O-ring.

If the O-ring is twisted

The O-ring must be removed and reinstalled uniformly with no twists

or other irregularities.

If there is hair, sand, lint or other debris on the O-ring contact surfaces

Wipe of any debris.

If there is a scratch, blemish or other imperfection on the O-ring contact surfaces

The strobe must be inspected by an authorized technician, and repaired if possible.

Contact Inon or you local Inon distributor for advice.

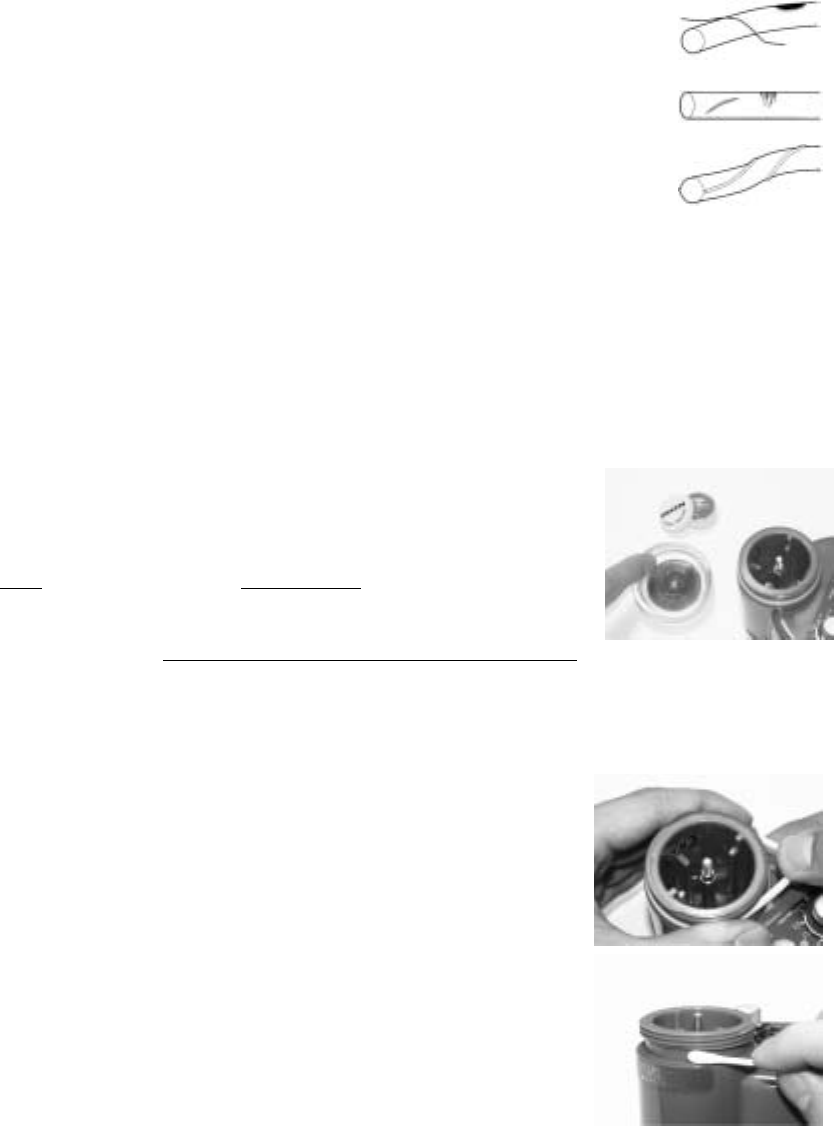

O-ring Maintenance Method

Grease: Inon O-rings are compounded with a special type of oil that

is not compatible with all grease types. Periodically re-grease the

O-rings only using the supplied Inon Grease. Do not use any other

grease, which may cause the O-rings to swell or deform, causing poor

seal and water leakage. Use of non-Inon grease will void warranty.

Field Maintenance: For periodic maintenance in the field it is not necessary to always

remove the O-ring and inspect the O-ring groove for each dive. If there is not any sand or

other debris visible it is ok to lightly grease the O-ring while it is seated in the O-ring groove.

For other maintenance follow the instructions below.

Removing O-ring

If you need to remove the O-ring for replacement, inspection, or to

check the O-ring groove etc., lightly squeeze the O-ring from the sides

(see figure) so it bulges out from one side. Grasp the extended part

and gently pull to remove. Never use sharp or metal objects to

remove O-rings as they may damage the O-ring itself or the O-ring

groove contact surface. If squeezing the O-ring from both sides does

not work, try gently using the edge of a credit card or similar object,

to pry the O-ring up a little so you can grasp it. Then clean any

residual grease or debris from the O-ring groove and contact surface, and check the condition