MHD56012 - Edition 8 7

3. HOOK LATCHES. Check operation of hook latches. Replace

if broken or missing.

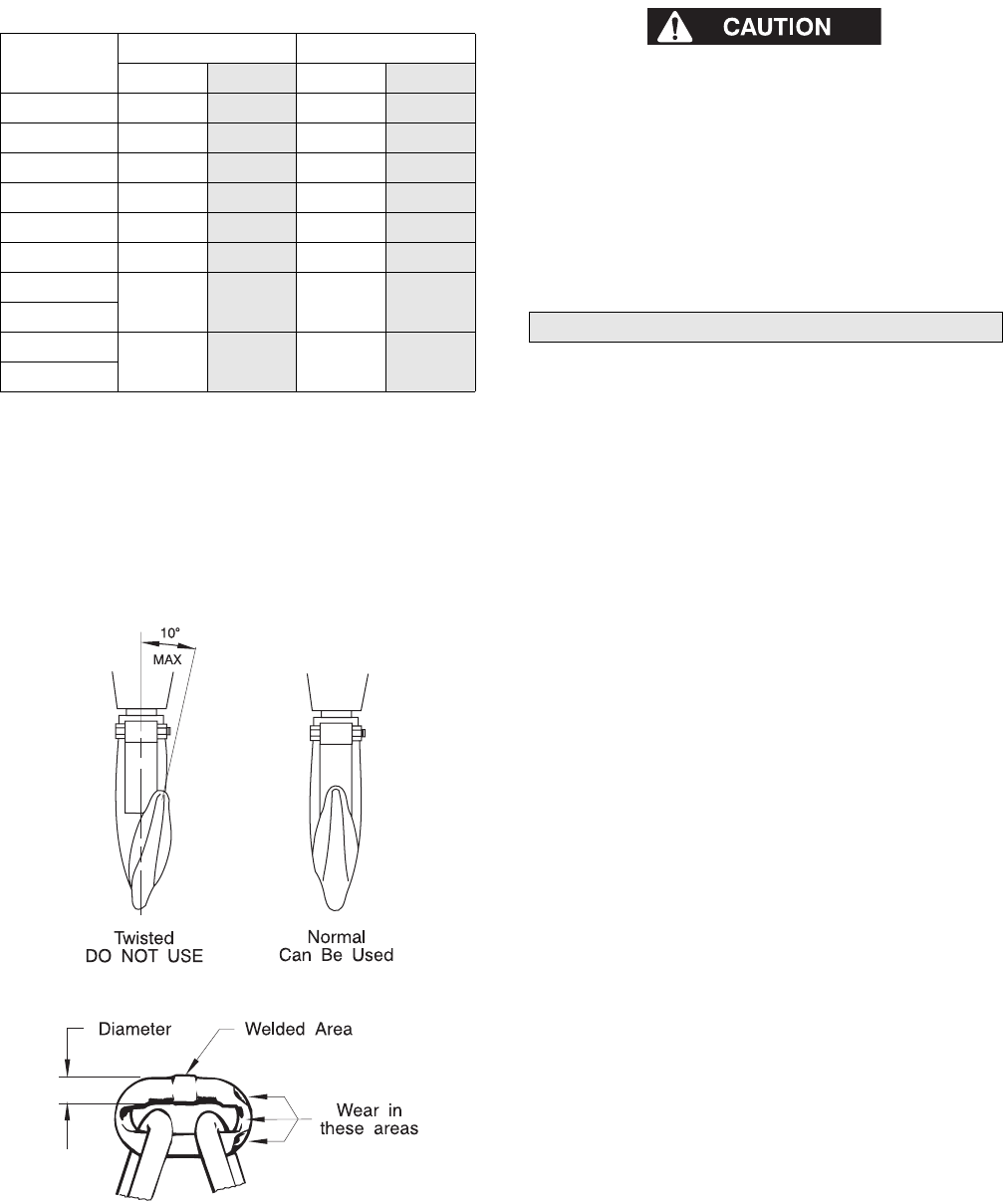

4. CHAIN. Refer to Dwg. MHP0102 on page 7. Examine each

link for bending, cracks in weld areas or shoulders, transverse

nicks and gouges, weld splatter, corrosion pits, striation

(minute parallel lines) and chain wear, including bearing

surfaces between chain links. Replace a chain that fails any of

the inspections. Check lubrication and lubricate if necessary.

Refer to “Load Chain” in “LUBRICATION” section.

(Dwg. MHP0111)

(Dwg. MHP0102)

• The full extent of chain wear cannot be determined by visual

inspection. At any indication of chain wear inspect chain and

load sheave in accordance with instructions in “Periodic

Inspection.”

• A worn load chain may cause damage to load sheave. Inspect

load sheave and replace if damaged or worn.

5. LOAD CHAIN REEVING. Refer to Dwg. MHP0042 on

page 9. Make sure welds on standing links are away from

load sheave. Reinstall chain if necessary. Make sure chain is

not capsized, twisted or kinked. Adjust as required.

Periodic Inspection

According to ASME B30.16, frequency of periodic inspection

depends on the severity of usage:

NORMAL HEAVY SEVERE

yearly semiannually quarterly

Disassembly may be required for HEAVY or SEVERE usage.

Keep accumulative records of periodic inspections to provide a

basis for continuing evaluation. Inspect all items in “Frequent

Inspection.” Also inspect the following:

1. FASTENERS. Check rivets, capscrews, nuts, cotter pins and

other fasteners on hooks, hoist body and chain bucket, if

used. Replace if missing and tighten or secure if loose.

2. ALL COMPONENTS. Inspect for wear, damage, distortion,

deformation and cleanliness. If external evidence indicates

the need, disassemble. Check gears, shafts, bearings, sheaves,

chain guides, springs and covers. Replace worn or damaged

parts. Clean, lubricate and reassemble.

3. HOOKS. Inspect hooks for cracks. Use magnetic particle or

dye penetrant to check for cracks. Inspect hook retaining

parts. Tighten, repair or replace if necessary. Refer to the

latest edition of ASME B30.10 (Hooks) for additional hook

inspection information.

4. CHAIN SHEAVES. Check for excessive wear or damage.

Replace if necessary.

5. BRAKES. Ensure proper operation. Brake must hold hoist

rated capacity. If load test indicates the need, disassemble.

Brake discs must be free of excess oil, any grease, unglazed,

uniform in thickness and at least 5/64 in. (2 mm) thick. Check

all other brake surfaces for wear, deformation or foreign

deposits. Inspect pawl brake. Teeth of ratchet gear should be

undamaged, and should stop gear rotation in the

counterclockwise direction. Check pawl spring for damage.

Clean and replace components as necessary.

6. SUPPORTING STRUCTURE. If a permanent structure is

used, inspect for continued ability to support load.

7. LABELS AND TAGS. Check for presence and legibility.

Replace if necessary.

8. END ANCHOR. Ensure end anchor on chain hoist is

engaged and unbent. Repair if damaged, replace if missing.

Refer to “Attaching End of Load Chain” in

“MAINTENANCE” section.

9. LOAD CHAIN. Measure chain for stretching by measuring

across five link sections all along chain. Refer to Dwg.

MHP0041on page 8 and Table 2. When any five links in the

working length reach or exceed discard length shown in

Table 2, replace entire chain. Always use a genuine

Ingersoll-Rand replacement chain.

Table 1: Hook Throat Dimension

Model No.

Throat Width Discard Width

in.

mm in. mm

VL2-005 1.22

31 1.4 35.6

VL2-010 1.33

34 1.54 39.1

VL2-015 1.5

38 1.72 43.7

VL2-020 1.61

41 1.86 47.2

VL2-030 1.85

47 2.12 54

VL2-050 2.01

51 2.31 58.6

VL2-080

2.8 71 3.21 81.6

VL2-100

VL2-150

3.54

90 4.07 103.5

VL2-200