4 KODAK VISION Premier Color Print Film / 2393

™

• H-1-2393t

Sound-Track Printing

Analog and digital sound-track printer setup and control

procedures for KODAK VISION Premier Color Print

Film / 2393 are similar to Film 2386 / E / 3386 / E, with

little or no change required.

Analog variablearea positivesound tracks ofsilver plus

dye usually restrict the exposure to the top two emulsion

layers by inserting KODAK WRATTEN Gelatin Filters

No. 12 and No. 2B

*

in the light beam. The optimum

variable-area sound-track density for the print is between

1.1 and 1.8 (read at 800 nm). You can achieve excellent

frequency response and a high signal-to-noise ratio in this

density range.

Note: With the same soundtrack negative, the print

density of VISION Premier Color Print Film / 2393 is

about .1 higher than VISION Color Print Film / 2383.

For a variable area positive sound track of silver plus

magenta dye only, printed from a negative sound track,

restrict the exposure to the top two emulsion layers by

inserting KODAK WRATTEN Gelatin Filter No.12 and

KODAK Color Compensating Filter 110 Cyan in the light

beam. The optimum variable-area sound-track density for

the print is between 0.8 and 1.1 (read at 800 nm). This

print density will provide a good compromise between

signal-to-noise ratio and frequency response.

Use cross-modulation test procedures to determine the

density of the sound-track negative required to produce

minimum cross-modulation distortion at the optimum

print density.

Digital sound-on-film soundtracks (e.g., Dolby Digital

and Sony SDDS) are dye only. Consult the system vendor

for performance recommendations.

SPLICING

Use tape splices for this film. Since ESTAR Base is

impervious tomost solvents,cement spliceswill not work.

Keep the knife on the tape splicer sharp and properly

aligned with the splicer platen. As the knife is lowered to

cut the film, slight leftward pressure will help ensure a

tight mesh of the cutting edges to give a clean cut. Taping

both sidesof the filmis recommended tominimize fold-up

or stretching. An ultrasonic weld splicer (Metric splicer)

also may be used.

You can use tape splices to intercut triacetate and

ESTAR Base film. However, because ESTAR Base prints

are 20 micrometres thinner, there may be a slight focus

difference when projecting on a large screen. To assure

compatibility, order the same type of film stock for all

prints used in a production.

* You can omit the No. 2B Filter without affecting the sound quality.

Using this filter is an operational convenience to

conform with printer setup for other products that require it.

STANDARD PRODUCTS AVAILABLE

Note: For availability of non-standard products, contact

your Kodak location.

IMAGE STRUCTURE

This film’s excellent sharpness captures the detail in the

printing negative for projection onto the largest of theatre

screens. Fine-grained emulsions, an ultra-thin layer

structure, intragrain absorbing dyes, and superior halation

protection contribute to its performance.

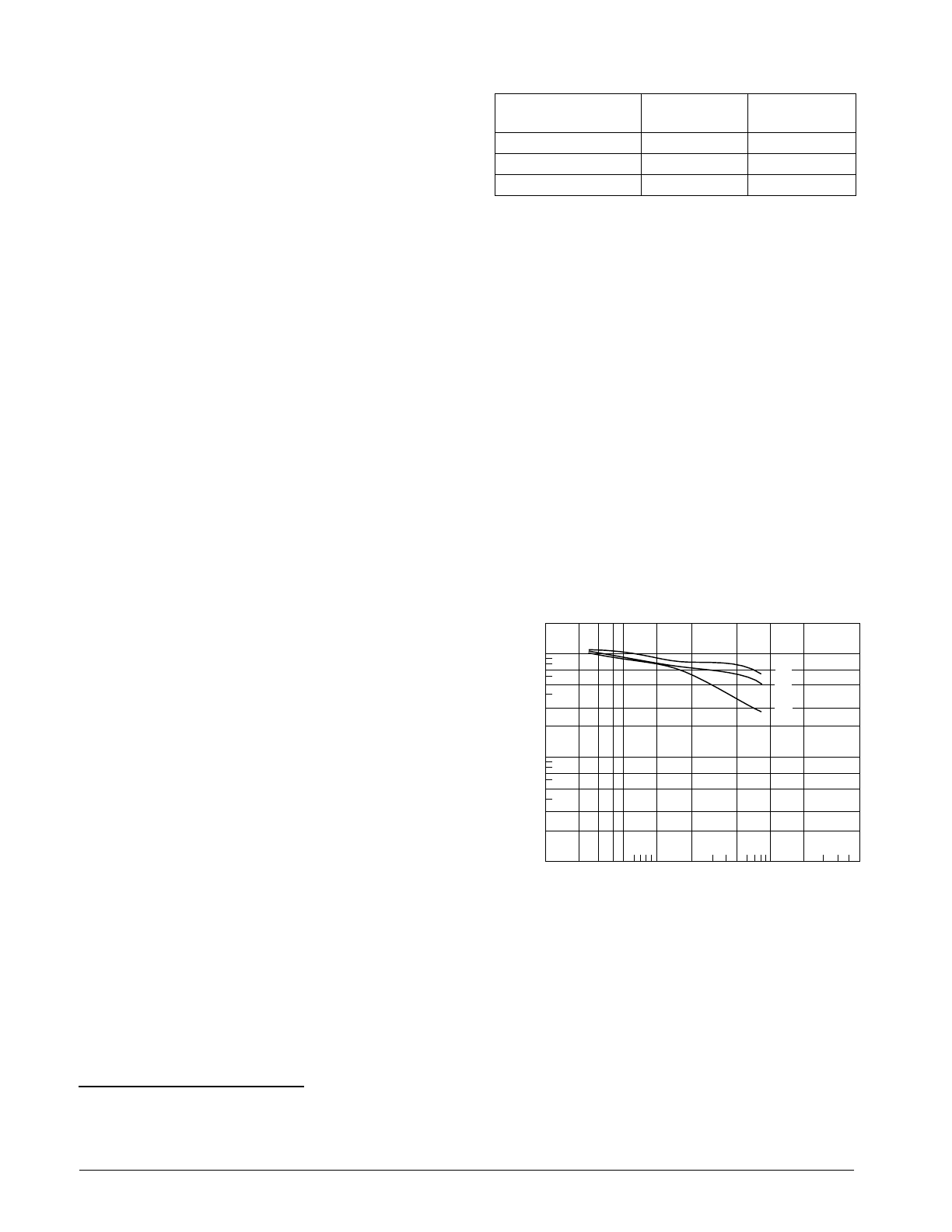

MODULATION-TRANSFER CURVE

This graph shows a measure of the visual sharpness of this

film. Thex-axis, “Spatial Frequency,” refers tothe number

of sine waves per millimetre that can be resolved. The

y-axis, “Response,” corresponds to film sharpness. The

longer and flatter the line, the more sine waves per

millimetre that can be resolved with a high degree of

sharpness — and, the sharper the film.

Modulation-Transfer Curves

Format

Length in Feet

(Metres)

Perforation

Pitch

35 mm SP666 2000 (610) KS-1870

35 mm SP779 4000 (1220) KS-1870

35 mm SP789 6000 (1829) KS-1870

F010_0058AC

1001 2 3 4 5 10 20 50 200 600

SPATIAL FREQUENCY (cycles/mm)

RESPONSE (%)

10

1

2

5

3

7

30

20

100

70

50

200

R

G

B