2 EASTMAN Color Internegative II Film 5272

™

/ 7272

™

• H-1-5272

LABORATORY AIM DENSITY (LAD)

CONTROL METHOD

To maintain optimum quality and consistency in the final

prints, the laboratory must carefully control the color

timing, printing, and duplicating procedures. Laboratory

Aim Density (LAD) Control Film provides a simple,

effective, and easily implemented control method for the

production of master positives and duplicate negatives

from negative originals.

All film in the printing original should be color timed

relative to LAD Control Film supplied by Eastman Kodak

Company. The reversal LAD control film specified may

be made on EASTMAN EKTACHROME Film 7240

flashed and processed to Status M densities of Red 1.10,

Green 1.10, and Blue 1.10. The LAD Control Film is

printed at the center of the printer range, usually

TAPE 25-25-25. Printer setup (speed, bulb voltage,

TRIM, filtration, etc.) is determined by printing the large

gray patch in the LAD Control Film to the specified

Laboratory Aim Density values on the duplicating film,

chosen to be at the center of the usable straight-line portion

of the duplicating film’s characteristic curves. The Status

M Laboratory Aim Density values for EASTMAN Color

Internegative II Film are as follows:

For making prints, the processed internegative may then

be timed relative to a negative LAD Control Film using

densitometry or an electronic color analyzer. On-aim

internegatives and duplicate negatives will normally time

near TAPE 29-29-29 compared to the negative LAD

Control Film printed at TAPE 25-25-25. The LAD on the

print film is a neutral gray of 1.0 visual density. The LAD

Control Method

*

assumes that the film and process

sensitometry are within specification.

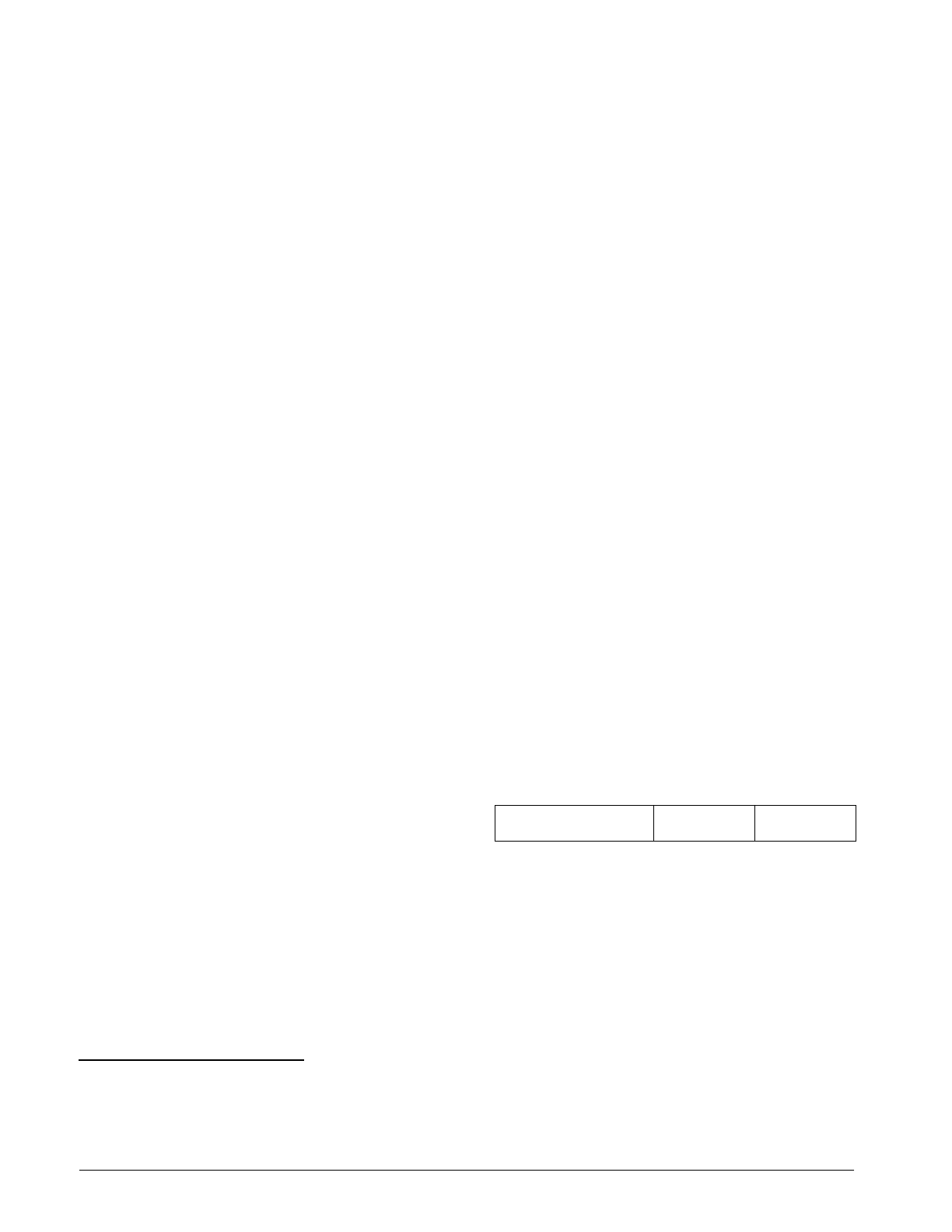

Red Green Blue Tolerance

0.90 1.30 1.70 ± 0.12 density

* The LAD control method is described in the paper “A Simplified

Motion-Picture Laboratory Control Method for Improved Color

Duplication,” by John P. Pytlak and Alfred W. Fleischer in the

October 1976 SMPTE Journal. Also refer to KODAK Publication No.

H-61, LAD—

Laboratory Aim Density

.

PRINTING CONDITIONS

In all printer setups for printing EASTMAN Color

Internegative II Film 5272 / 7272, include a heat absorbing

(infrared) filter such as a KODAK Heat Absorbing Glass,

No. 2043, and a KODAK WRATTEN Gelatin Filter No.

2B to absorb ultraviolet (UV) light. For high light output

with very long bulb life, operate the printer bulb at

approximately 80 percent of rated voltage. Use a

well-regulated constant-current dc power supply.

Print the LAD Control Film at the center of the printer

balance range, usually TAPE 25-25-25 on an additive

printer. Print other scenes in the original as determined by

color timing relative to the reversal LAD Control Film.

Choose the printer speed and filtration to normalize the

additive TRIM settings near the center of their range to

allow for slight variations in film and printer.

On subtractive printers, choose the filter pack and light

control for both the removal and addition of filters for

color correction. You can use EASTMAN Lamphouse

Modification Filters in subtractive printers to more closely

balance the spectral characteristics of subtractive

lamphouses with additive lamphouses so that prints made

on a subtractive printer more closely match those made on

additive printers. On optical printers, set the lens aperture

considering sharpness, depth of focus, and light

transmittance characteristics. Use ground glass or other

diffusers to improve uniformity of illumination. Clean and

align optics for optimum light output and uniformity.

IMAGE STRUCTURE

The modulation-transfer curve, rms granularity, and

resolving-power data were generated from samples of

EASTMAN Color Negative II Film exposed with tungsten

light and processed as recommended in Process ECN-2

chemicals. For more information on image-structure

characteristics, see KODAK Publication No. H-1, KODAK

Professional Motion Picture Films.

Diffuse RMS Granularity

*

Less than 5

* Read at a net diffuse visual density of 1.0, using a 48-micrometre

aperture.

Resolving Power

†

† Determined according to a method similar to the one described in

ISO 6328-1982,

Photography—Photographic Materials—

Determination of ISO Resolving Power.

TOC 1.6:1

TOC 1000:1

80 lines/mm

160 lines/mm