2 EASTMAN Fine Grain Release Positive Film 5302™ / 7302™ • H-1-5302

PROCESSING

Use the following process recommendations as starting

points for a typical continuous-immersion processor using

formulas presented in KODAK Publication No. H-24.15,

Manual for Processing EASTMAN Motion Picture Films,

Module 15. The processing times may require modification

for a particular machine.

Notice: Observe precautionary information on product

labels and on Material Safety Data Sheets.

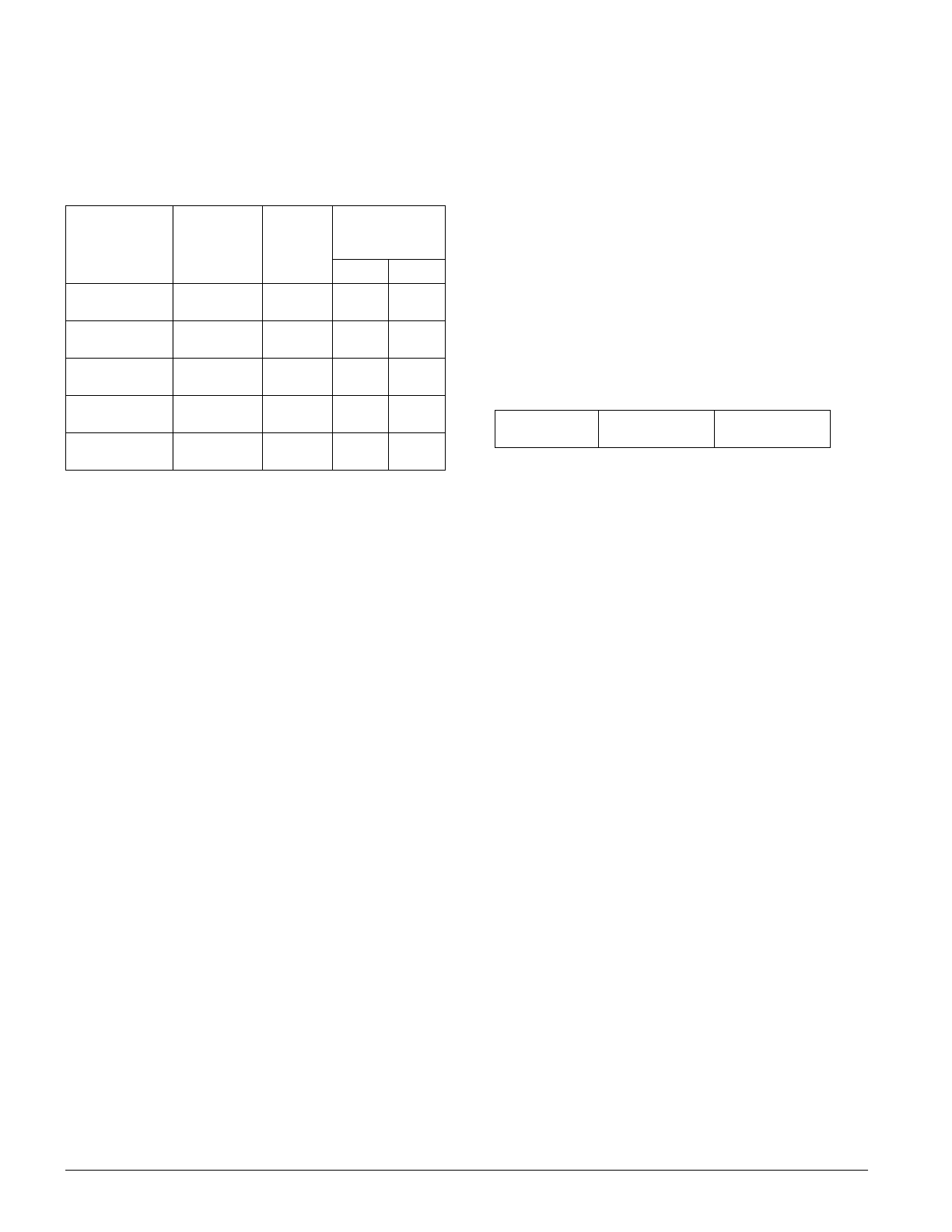

Processing

Step

Temperature

˚C (˚F)

Time

(min:sec)

Replenishment

Rate

(mL per 100 ft)

35 mm 16 mm

KODAK

Developer D-97*

* Agitation in the developer and in the fixing bath should be by

recirculation through submerged spray jets that impinge on the film

strands.

21 ± 0.3

(70 ± 0.5)

†

† Develop to the recommended control gamma of 2.4 to 2.6 Status M

Densitometry (Blue).

650

(D-97R)

325

(D-97R)

Stop Rinse‡

‡ Fixer-laden water overflow from the first wash tank (pH approximately

6.0).

21 ± 1

(70 ± 2)

0:50 12,000 6,000

KODAK

Fixing Bath F-5*

21 ± 1

(70± 2)

6:00 600 300

Wash

(countercurrent)

21 ± 1

(70 ± 2)

10:00 12,000 6,000

Dry

35

(95)

§

§ Drying depends on many factors such as air temperature, relative

humidity (RH), volume, rate and distribution of the air flow, final

squeegeeing, etc. In a conventional convectional-type drying cabinet

with air at about 35˚F (95˚C) and 40- to 50-percent RH, drying will take

15 to 20 minutes. In an impingement-typedrying cabinet, however, with

a highertemperature andlower RH,drying timeis greatlyreduced. WIth

either type of dryer, the film should be dry without tackiness

1

⁄

2

to

2

⁄

3

of

the way through. Upon cooling to room temperature after leaving the

dryer,the filmshould beatequilibrium withthe roomair atapproximately

50-percent RH.

——

LUBRICATION

All films destined for projection require some lubrication to

prevent problems during early projection life. Edge waxing

with a paraffin wax solvent solution provides a simple,

inexpensive, and adequate lubrication for 35 and 70 mm

projection prints. For 8 and 16 mm prints, an overall

lubricant may be required.

IMAGE STRUCTURE

The modulation-transfer curves, the diffuse rms granularity,

and the resolving power data were generated from samples

of 5302 Film exposed with tungsten light and processed as

recommended in KODAK Developer D-97 at 21˚C (70˚F) to

the recommended control gamma. For more information on

image-structure characteristics, see KODAK Publication

No. H-1, KODAK Motion Picture Film.

Diffuse RMS Granularity* 8

* Read at a net diffuse visual density of 1.0, using a 48-

micrometre aperture.

Resolving

Power†

† Determined according toa method similar tothe one described

in ISO 6328-1982,

Photography—Photographic Materials—

Determination of ISO Resolving Power.

TOC 1.6:1

TOC 1000:1

63 lines/mm

125 lines/mm