2 KODAK VISION3 500T Color Negative Film 5219 / 7219 / SO-219 • H-1-5219t

DARKROOM RECOMMENDATIONS

Do not use a safelight. Handle unprocessed film in total

darkness.

EXPOSURE TABLE - TUNGSTEN LIGHT

At 24 frames per second (fps), 170-degree shutter

opening:

Use this table for average subjects that contain a

combination of light, medium, and dark colors. When a

subject includes only pastels, use at least 1/2 stop less

exposure; dark colors require 1/2 stop more exposure.

Lighting Contrast -

The recommended ratio of key-light-plus-fill-light to fill

light is 2:1 or 3:1. However, you may use 4:1 or greater when

a particular look is desired.

RECIPROCITY CHARACTERISTICS

You do not need to make any filter corrections or exposure

adjustments for exposure times from 1/1000 of a second

to 1 second. In the 10-second range, increase exposure 1

stop and use a KODAK Color Compensating Filter CC 10R.

PROCESSING

Process in Process ECN-2.

Most commercial motion-picture laboratories provide a

processing service for these films. See KODAK Publication

No. H-24.07, Processing KODAK Color Negative Motion

Picture Films, Module 7 available online at http://

www.kodak.com/US/plugins/acrobat/en/motion/

support/processing/h247/h2407.pdf, for more

information on the solution formulas and the procedure for

machine processing these films. There are also

pre-packaged kits available for preparing the processing

solutions. For more information on the KODAK ECN-2 Kit

Chemicals, check Kodak's Motion Picture Films for

Professional Use price catalog.

IDENTIFICATION

After processing, the product code numbers 5219 (35

mm), 7219 (16 mm), or SO-219 (16, 35, and 65 mm;

edgeprint shows 0219) emulsion, roll, and strip number

identification, KEYKODE Numbers, and manufacturer/film

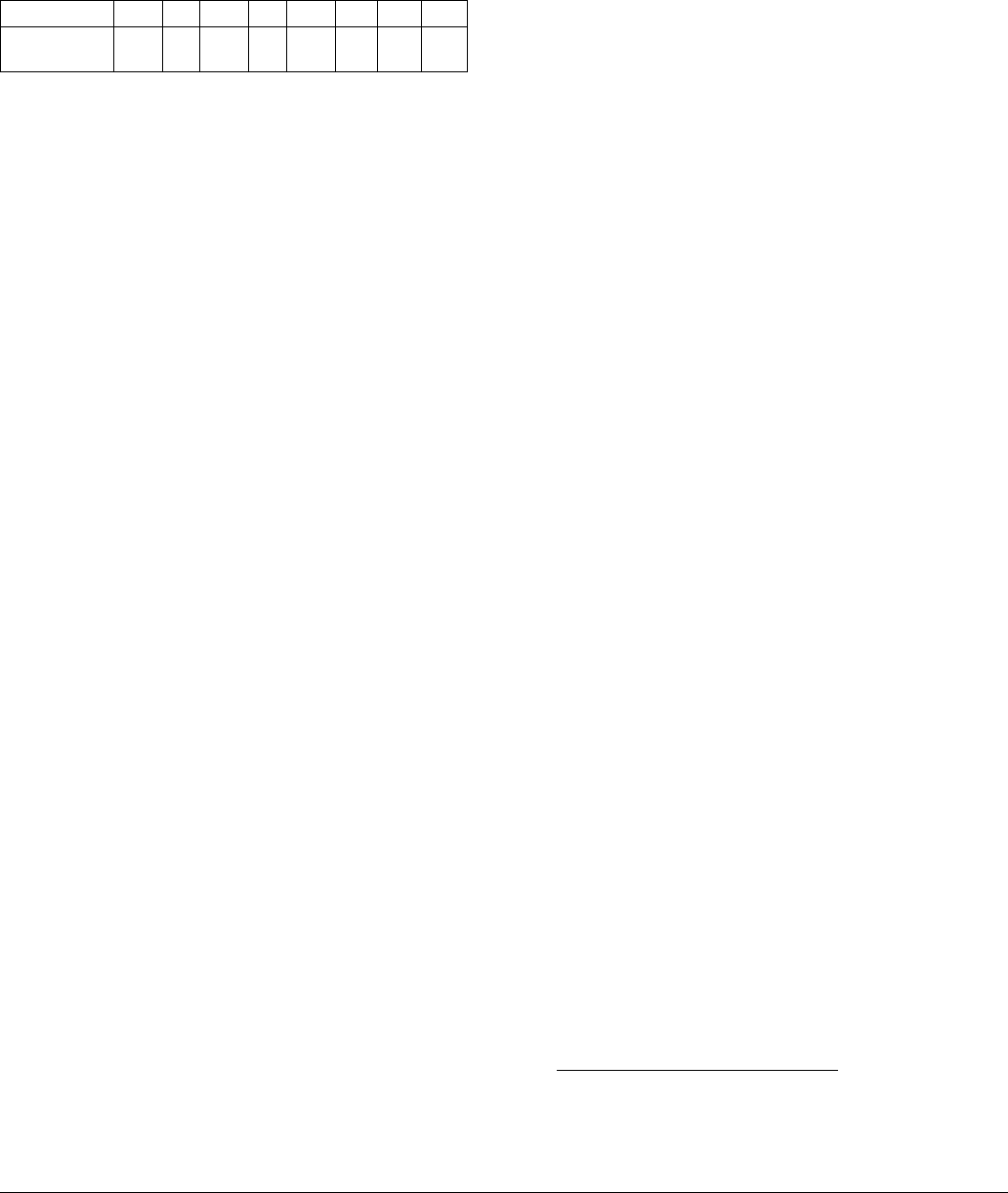

Lens Aperture f/1.4 f/2 f/2.8 f/4 f/5.6 f/8 f/11 f/16

Footcandles

Required

510204080160320640

identification code (EJ) are visible along the length of the

film.

LABORATORY AIM DENSITIES (LAD)

To maintain optimum quality and consistency in the final

prints, the laboratory must carefully control the color

timing, printing, and duplicating procedures. To aid in color

timing and curve placement, negative originals should be

timed relative to Laboratory Aim Density (LAD) Control

Film supplied by Eastman Kodak Company.

2

The LAD

Control Film provides both objective sensitometric control

and subjective verification of the duplicating procedures

used by the laboratory.

In the LAD Control Method,

3

the electronic color

analyzer used for color timing is set-up with the LAD

Control Film to produce a gray video display of the LAD

patch, corresponding to 1.0 neutral density (gray) on the

print. The negative printing original is then scene-to-scene

timed. There are specific LAD values for each type of print

or duplicating film that the original can be printed on. For

print films, the LAD patch is printed to a neutral gray of 1.0

visual density. For duplicating films, the specified aims are

at the center of the usable straight-line portion of the

sensitometric curve of the film.

Due to normal variations in exposure and processing of

color negative films, particular scenes may not print

exactly at the same printer lights as the LAD Control Film.

The LAD Control Film is intended as a set-up tool for

electronic color analyzers and printers. It is NOT a

reference that every scene must match. Normal

film-to-film and scene-to-scene exposure variability is

accommodated by the color timing (grading) process, on

an electronic color analyzer set up with the LAD Control

Film. Normally exposed and processed color negatives will

typically print well within the range of an additive printer

setup with the LAD Control Film, although SIGNIFICANT

or UNEXPECTED departures from this center point

balance may indicate an exposure/filtration problem with

the cinematography or with the process control. Some

specialized films and/or specialized negative processing

techniques (push-processing, pull-processing,

"skip-bleach" processing, etc.) may require more extreme

adjustment from the LAD printing condition to attain

desired results.

More information is contained in KODAK Publication

H-61, Laboratory Aim Density, available online at

http://www.kodak.com/US/en/motion/support/

lad.jhtml.

FILM-TO-TAPE TRANSFERS

When you transfer the film directly to tape, you can set up

the telecine using KODAK Telecine Analysis Film (TAF)

2. Direct any inquiries to one of the regional sales offices.

3. Use of the LAD Control Method is described in the paper, "A Simplified

Motion-Picture Laboratory Control Method for Improved Color

Duplication," by John P. Pytlak and Alfred W. Fleischer in the October 1976

SMPTE Journal.