11

• Conductivity is less than 20 µS/cm.

• Electronic component failure.

• 4-20 mA is not scaled same as Loop

device.

• Loop device is not scaled same as

Magmeter.

• Range Jumper not placed correctly.

• Defective Magmeter

• Magmeter installed too close to

upstream obstruction.

• Magmeter electrodes are coated with

solids.

• Magmeter electrodes exposed to air

bubbles/pockets.

• Electrical noise is interfering with the

measurement.

• New sensor, metal surface not

properly conditioned.

• Output is not 0 when fl ow is stopped.

• Frequency or Current

output is erratic.

• Output is 22.1 mA.

• Electrode not adequately conditioned.

• Pipe is empty, Magmeter is not in fl uid.

• Electrical noise is interfering with the

measurement.

• Defective Magmeter

Symptom

Possible Cause Possible Solution

• Frequency output is inoperative

• Loop output is inperative.

• Move the Magmeter upstream at least

10 pipe diameters from obstruction.

• Clean the electrodes with soft cloth.

Do not use abrasives.

• Eliminate air bubbles in the pipe.

• Remove the Magmeter and reinstall

with the fl ow direction arrow on the

sensor body pointed DOWNSTREAM.

• Modify grounding as required

to protect the Magmeter from

interference.

• Soak sensor overnight in fl uid.

10.2 Troubleshooting

• Soak sensor overnight in fl uid.

• Confi gure pipe so electrodes are

always in fl uid.

• Modify grounding as required

to protect the Magmeter from

interference.

• Set low fl ow cutoff higher.

• Return to factory for service.

• Respan Loop device to match

Magmeter.

• Set Range Jumper correctly.

• Return to factory for service.

• FMG-3000 is wrong model.

• Blue jumper not in correct position.

• Wiring is not correct.

• Frequency input to other

manufacturer's fl ow instrument does

not have pull-up resistor.

• Frequency model is FMG-3001 and

FMG-3101 series.

• Place blue jumper correctly. (Sec. 5

pg. 9)

• Check wiring, make corrections.

• Install 10kΩ resistor. Sec 8.1, pg. 6)

• Unsuitable application for Magmeter.

• Return to factory for service.

• 4-20 mA output is incorrect.

10. Maintenance

The FMG-3000 series Magmeter requires very little maintenance. There are no user-serviceable components in the Magmeter.

• If the fl uid contains deposits and solids that may coat the electrodes, a regular cleaning schedule is recommended.

• Do not use abrasive materials on the metal electrodes. Clean with soft cloth and mild detergent only.

• Use a cotton swab and mild detergent to remove deposits on the metal electrodes at the tip of the sensor.

10.1. Environmental Recommendations:

• When used properly, this product presents no inherent danger to the environment.

• Please follow local ordinance when disposing of this or any product with electronic components.

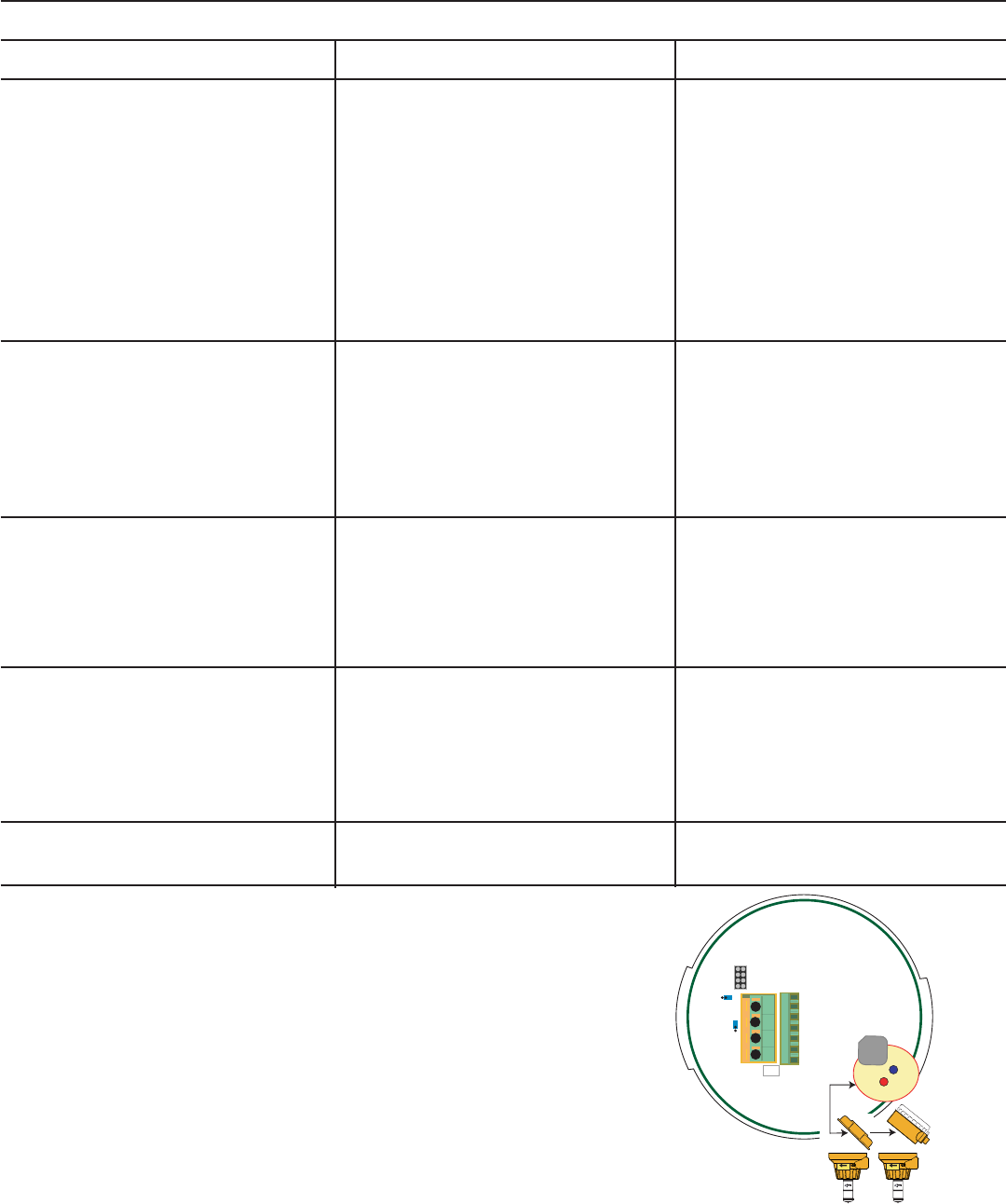

Troubleshooting with the RED and BLUE lights

The FMG-3000 uses two colored LEDs to indicate the status of the instrument.

They are located at the top of the magmeter, inside the clear plastic cap.

No Lights: The power is off or the sensor is not connected

Solid Blue (D7): The power is on but there is no fl ow in the pipe.

Blinking Blue (D7): Normal operation, blink rate is proportional to the fl ow rate.

Alternating Red-Blue: Empty pipe indication (electrodes are not wet.)

Blinking Red (D6): System errors (Electrical noise interference)

Solid Red (D6): Instrument error (defective electronics component)

1

2

3

4

JP2

D7

D6

Flow Flow