6 7

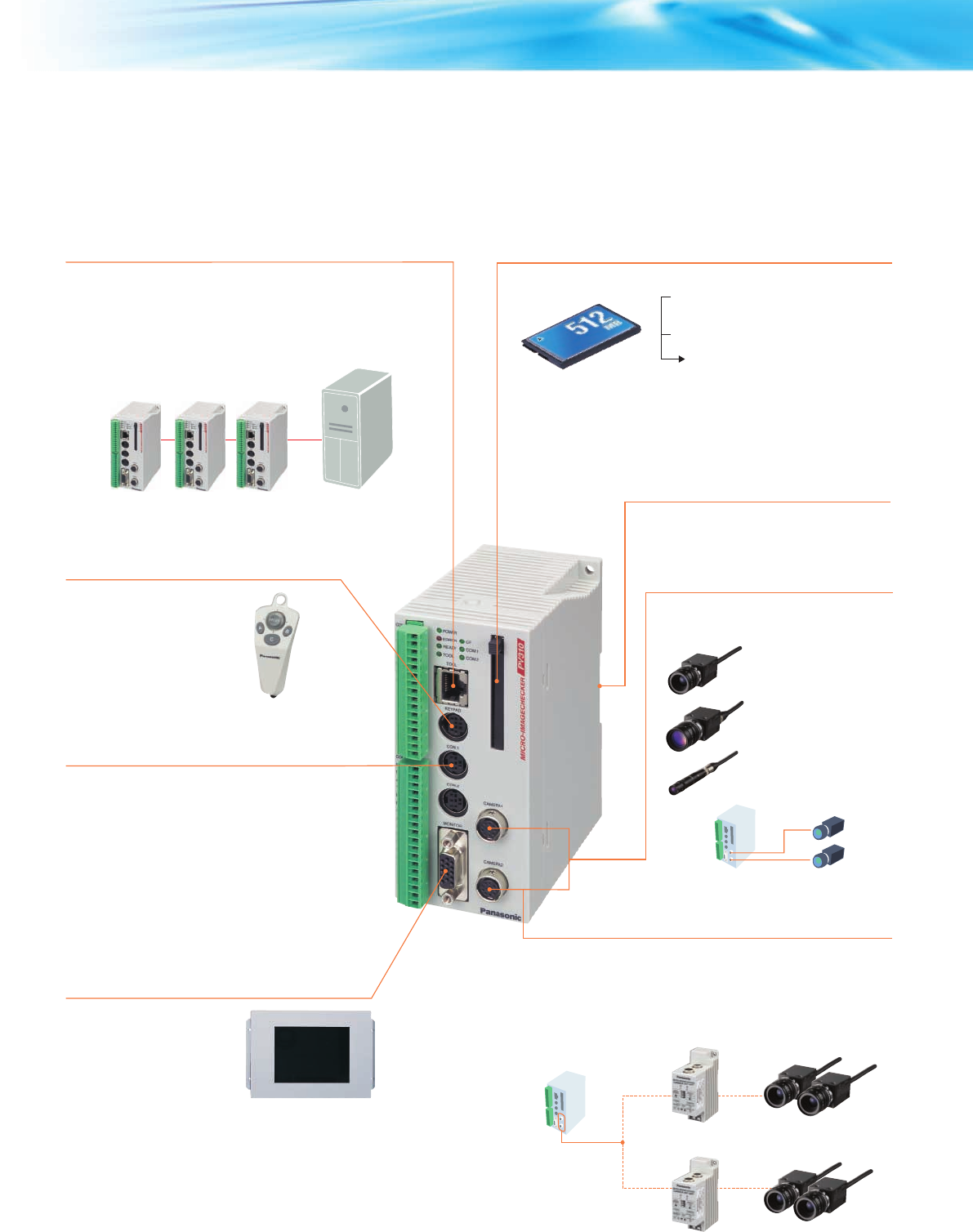

Full Selection of Interfaces

External interfaces are essential for image processing

devices of the future. The PV310 is equipped with a full

selection of interfaces that rival even large-scale devices.

PV310

PV310

Two cameras

Operation Keypad

•

In RUN mode:

•

In the setting mode:

• Backs up setting data and image data

captured by the unit.

The dedicated keypad with an

ergonomic structure provides

excellent operability.

Up to two identical cameras can be

connected. The following camera types

are available.

Functions

The numerical output function has been greatly

simplified so that even a novice can set it easily.

Operation has also become even easier as both

numerical calculations and judgment output can now

be set on the same screen (up to 96 formulas).

Upgraded

Detection of sub-pixel position possible with gray

scale matching. In addition, using the gray scale

differential processing function, shape inspection,

etc. can also be carried out simultaneously. Memory

capacity has been increased 4 times over previous

models, allowing support for an even wider range of

applications.

Based on the position information obtained by the

matching function, the registered object and detected

object are overlapped and compared on a pixel-by-

pixel basis. Any pixels with a difference in brightness

over a certain level are detected. The area value of

such pixels can then be used to make pass/fail

judgments.

Feature Extraction

Features, such as the number of objects, workpieces,

area, central coordinates, angle of the main axis,

projection width or perimeter length can be extracted.

Gray Scale Window

An inspection area can be created in a 256 gray

scale image, with a rectangular, circular or polygonal

shape, over the area where object detection is to take

place. An average value for the brightness data (gray

scale value) for all pixels in that area can be

calculated.

360° Contour Matching

Stable position detection is possible even for objects

that overlap because their contours can be extricated.

The range of settings has been doubled and support

has been added for 4 cameras.

Supported Models:

• Matsushita Electric Works PLCs

• OMRON Corporation - C, CV and CS1 series

• Mitsubishi Electric Corporation - A, Q and FX series

• Rockwell Automation DF1 protocol

• Fuji Electric SX series

Ethernet Connection

• The PV310 can be connected to a LAN using high-speed Ethernet

(100BASE-TX) to meet various application requirements.

• Captured images and measurement data can be transmitted to a PC at

high speed even during operation.

• The inspection status of multiple PV310 units can be monitored from a

single PC.

• With the high-speed connection to a PC, backing up image data is also

easy.

PC

External Memory (CF Card) Support

Note: Backup image data can be used as

regular bitmap files on a PC.

DIN Rail Installation

Connection of up to Two

Identical Cameras

Connection of up to Four Cameras

by a Camera Switching Unit

• Can save captured images.

[Storage capacity:

Approx. 2,000 images (512 MB)]

• Saves inspection results.

Facilitates trend tracking and data

analyses.

Cameras

PV310

Inspection programs for as many

as 64 product types can be set.

Smart Matching

Improved

Differential Function

Numerical Calculation/

Judgment Output

NG

Detects registered

template

Detection Image

Template

Matching

detection

Difference detected =

Previous

The shape of the inspection area can be set to

match particular targets. Mask area settings

can also be combined to allow efficient

inspections to be carried out only on the

necessary parts.

Mask

Rotation/Position Adjustment

Mask

Multiple Adjustment

Highly accurate and reliable inspection is realized by automatically adjusting object orientation

and stop position deviation.

Complicated adjustments are also possible using the multiple adjustment function.

Search area Inspection object

Position

adjustment 1

Position

adjustment 2

Detection Image

Position Adjustment

Rotation Adjustment

Multiple Adjustment

Priority Adjustment

Inspection

area

Mask

PLC Link Function

• The PV310 can communicate easily with external

devices, such as PLCs, using the RS232C port.

• The PV310 can be connected to other companies'

PLCs without requiring additional programming. Of

course it can be connected to our PLCs, too.

VGA Monitor

Judgment results and program

settings are displayed in color for

outstanding visibility.

(Captured images are in black

and white.)

Up to four identical standard or double-speed random cameras can be

connected using a camera switching unit (option: ANPV3700).

* Excluding Ultra-compact camera

This connection is ideal for:

• Control of different inspections by a single controller unit

• Inspection of wide areas, and positioning of workpieces during the LCD

lamination process, etc.

Note: Commercially available VGA monitors may also be connected

(devices supporting horizontal synchronous frequency: 31.466KHz

and vertical synchronous frequency: 59.94KHz only.)

Operation cannot be guaranteed with devices from other manufacturers.

Standard camera

[ANM832 (CE)]

Double-speed random

camera [ANM831]

Ultra-compact camera

[ANPVCA1012]

Camera switching unit

(ANPV3700)

•

Camera Switching Mode

Images taken by either of two cameras

connected to the camera switching unit

are output to the PV310.

* Available for ANM832 (CE) and

ANM831

•

Camera Image Split Mode

(top/bottom split and left/right split)

Half images taken by two cameras are

combined into one, which is then

output to the PV310.

* Available for ANM832 (CE) only