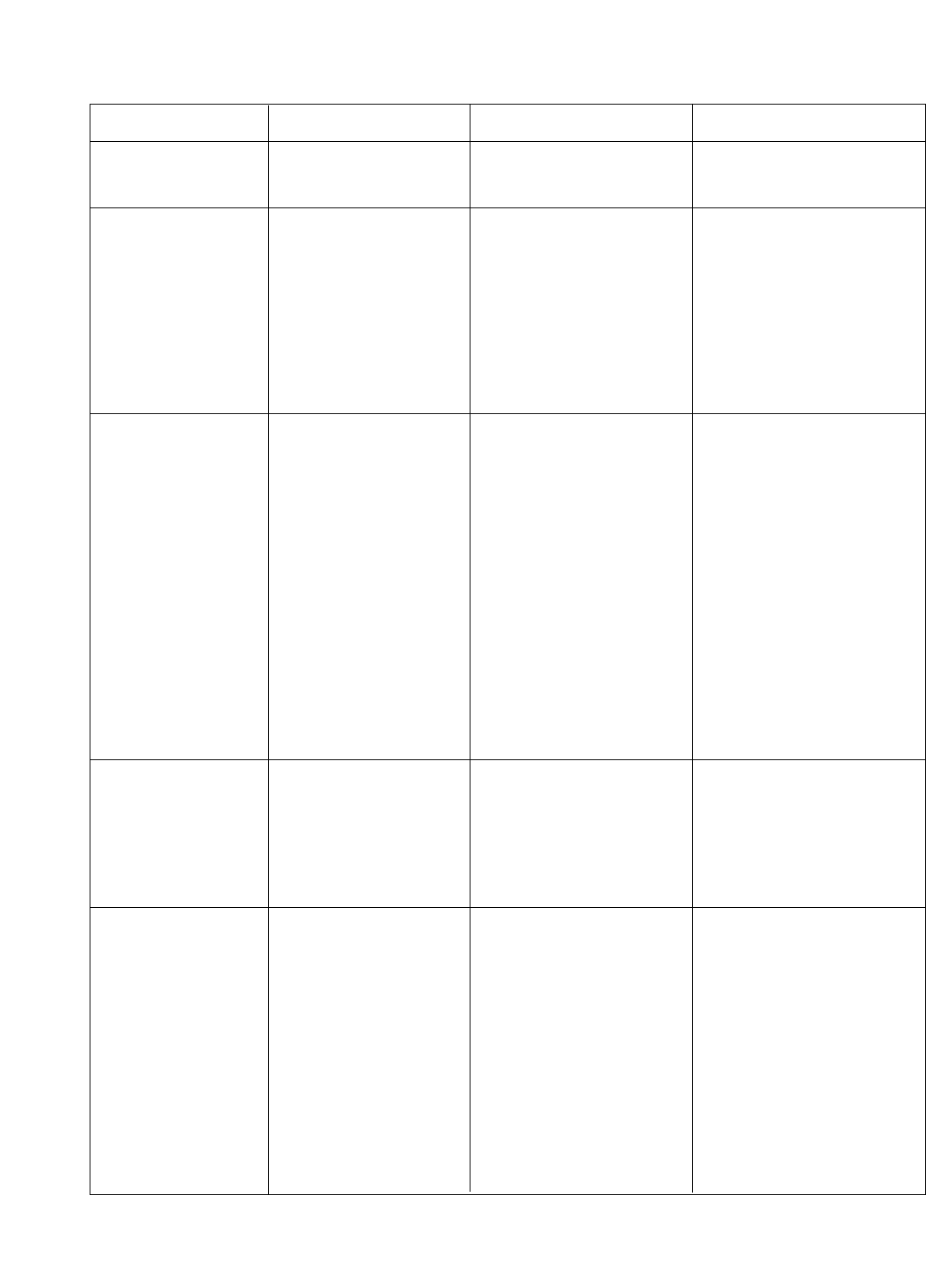

14

Symptom Possible Cause

Field Test

Remedy

1. Valve improperly

installed.

1. Open circuit in

modulator coil.

2. Plunger missing, jammed

or improperly installed.

3. Ruptured main or

balancing diaphragm.

1. No voltage to the

amplifier.

2. Short in modulator coil

circuit.

3. Short in TS144 circuit.

4. Faulty amplifier.

1. Incorrect by-pass metering

valve adjustment.

2. Excessive negative

burner pressure.

1. Faulty amplifier.

2. Short in T244 or

TS244/TD244 circuit.

1. Arrow on side of valve

should point in direction

of gas flow.

1. Remove wires connected

to amplifier terminals 6 &7

and measure resistance.

MR212 (60-80 ohms), M611

(45-55 ohms).

2. Inspect. Plunger should be

installed to operate freely in

solenoid sleeve.

3. Disassemble valve for

inspection of internal parts.

1. Check for 24V AC at

amplifier terminals 8 & 9.

2. Measure resistance per

item 2.

3. Remove wires connected to

amplifier terminals 1, 2 & 3.

Measure resistance across

wires 1 & 3. Meter should

read greater than 2500 ohms.

4. Follow procedures outlined

in “Preliminary Circuit

Analysis” in Section IX.

1. See Valve Adjustments -

Section IX.

2. Close main gas supply and

measure manifold pressure

with blower operating.

Should be less than 1.5”

W.C. negative pressure.

1. Follow procedures outlined

in “Preliminary Circuit

Analysis” in Section IX.

2. Remove wires connected

to amplifier terminals 4 & 5.

Set T244 or TD244 to max-

imum setting. Measure

resistance across wires.

Meter should read 6000

ohms ± 1000 (T244). If

TS244/TD244 are used,

meter should read 4500

ohms ± 1000 (TS244) and

2100 ohms ± 150 (TD244).

1. Install properly.

1. If proper resistance values

are not observed, replace

modulator head or repair

wiring.

2. Clean or replace plunger is

necessary.

3. Replace diaphragm if

ruptured.

1. Provide 24V AC to amplifier.

Refer to item K1.

2. If proper resistance values are

not observed,replace the mod-

ulator head or repair wiring.

3. If readings are incorrect,replace

the TS144 or repair wiring.

4. If power source and

modulator coil check out

(items 5 & 6) but proper

modulating voltages cannot

be obtained, then amplifier

may be assumed at fault.

Install replacement amplifier.

1. Adjust to proper low fire.

2. If greater than 1.5”

negative pressure, check

equipment for clogged

filters and other inlet air

restrictions. For other

solutions, consult factory.

1. If amplifier is proven at fault,

install replacement amplifier.

2. If reading is incorrect, replace

The T244,TS244/TD244 or

repair wiring.

Control circuits external to Series 44 can cause burner malfunction. Always check manual valve to be

certain gas is on, and check limit controls for normal operation.

A. No Gas Flow.

B. Continuous Low

Fire (Electronics

OK).

C. Continuous Low

Fire (Electronics

Problem).

D. Incorrect Low Fire.

E. Continuous

Minimum Discharge

Air Temperature.

TROUBLESHOOTING GUIDE

Series 44 Room Temperature Control Reproduced with permission from Maxitrol® Company