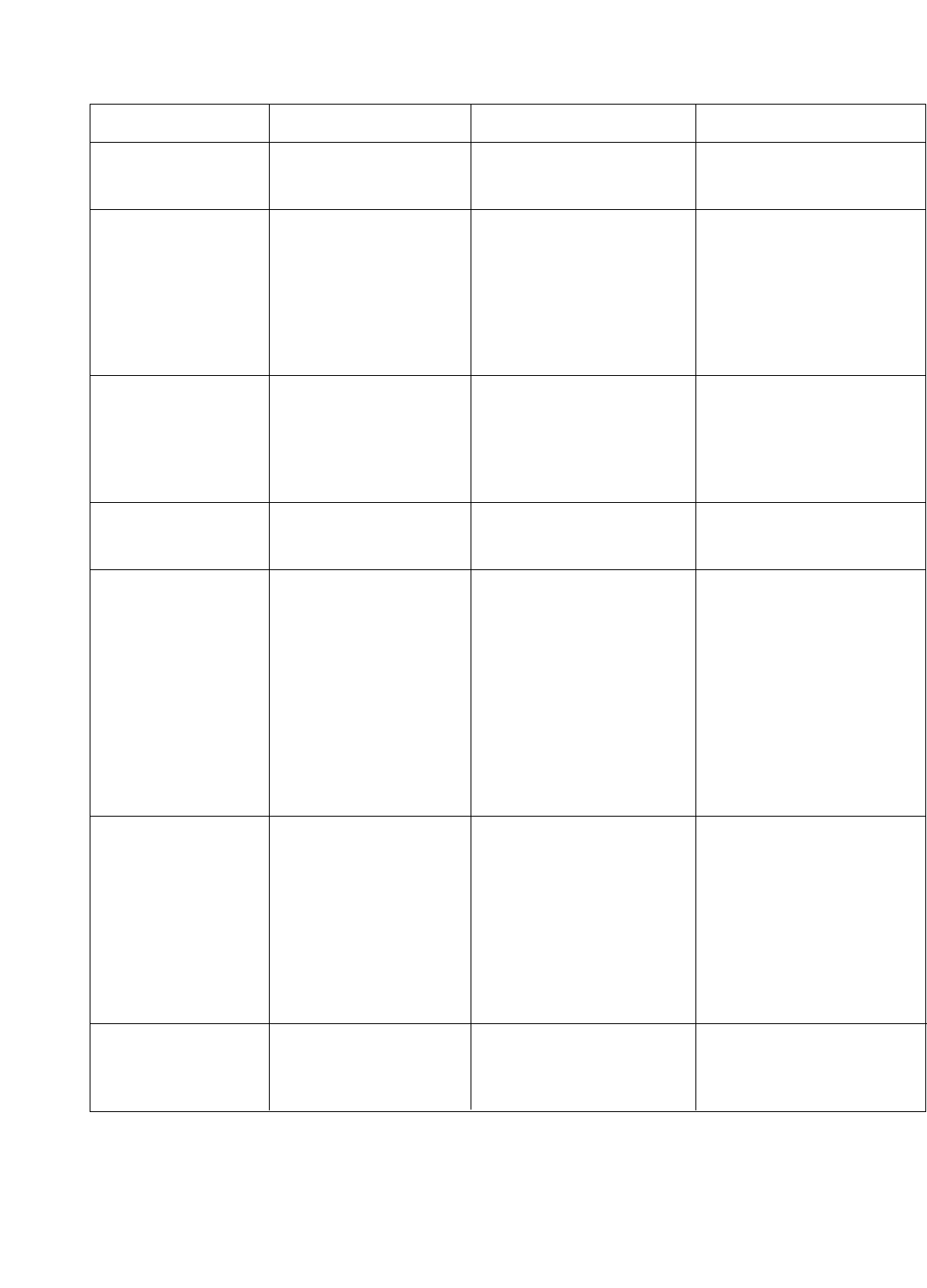

15

Symptom Possible Cause

Field Test

Remedy

E. continued

F. Incorrect

Maximum or

Minimum

Discharge Air

Temperature.

G. Continuous High

Fire (Electronics

OK).

H. Continuous High

Fire (Electronics

Problem).

I. Incorrect High Fire

J. Continuous

Maximum Discharge

Air Temperature.

K. Burned out

Transformer. No

Voltage to Amplifier.

3. Follow procedures outlined

in “Preliminary Circuit

Analysis” in Section IX.

1. Compare sensed

temperature reading at

TS144 with average

discharge air temperature.

2. Follow procedures outlined

in “Preliminary Circuit

Analysis” in Section IX.

1. Remove bottom plate and

inspect valve and seat.

2. Inspect. Plunger should

be smooth and clean and

operate freely in solenoid

sleeve.

1. Measure resistance per

item C3.

1. Read inlet pressure at valve

using manometer with

heater operating at full fire.

Pressure should be at least

equal to the sum of: outlet

pressure setting and

pressure drop of the valve

plus 1.0” W.C.

2. Read outlet pressure using

manometer and compare

with the pressure stated

on the specification plate.

1. Follow procedures outlined

in “Preliminary Circuit

Analysis” in Section IX.

2. Measure resistance per

item E2.

3. Follow procedures outlined

in “Preliminary Circuit

Analysis” in Section IX.

1. Measure resistance per

item B1.

3. If proper action is obtained,

first check item E2.

Recalibrate if necessary.

1. Move TS144 to location

where average temperature

can be sensed.

2. If proper temperatures are

not observed, refer to

Discharge Air Temperature

calibration procedures.

1. Clean, replace valve and/or

seat if necessary.

2. Clean, or if necessary,

replace plunger

1. If readings are incorrect,

replace the TS144 or repair

wiring.

1. Increase inlet pressure if

possible or change to larger

valve. Consult factory

about possibility of using

special spring to reduce

pressure drop on selected

installations.

2. See Valve Adjustments in

Section IX.

1. If amplifier is proven at

fault, install replacement

amplifier.

2. If reading is incorrect,

replace T244,

TS244/TD244 or repair

wiring.

3. If proper action is obtained,

first check item J2.

Recalibrate if necessary.

1. If proper resistances are

not observed, replace

modulator head or repair

wiring.

Control circuits external to Series 44 can cause burner malfunction. Always check manual valve to be

certain gas is on, and check limit controls for normal operation.

3. Incorrect space

temperature calibration.

1. Improper TS144

location.

2. Incorrect discharge

air temperature

calibrations.

1. Foreign material

holding valve open.

2. Plunger jammed.

1. Open circuit in TS144.

1. Inlet pressure too low.

2. Incorrect outlet

pressure adjustment.

1. Faulty amplifier.

2. Open circuit in T244

or TS244/TD244.

3. Incorrect space

temperature calibration.

1. Short in modulator coil

circuit.

TROUBLESHOOTING GUIDE

Series 44 Room Temperature Control continued Reproduced with permission from Maxitrol® Company