19

D. Belt Tension and Adjustment

Belt tension is adjusted during the initial run-in and test

periods at the factory. However, the belts are run as slack

as possible to prevent excessive damage to the bearings,

yet tight enough to prevent slippage.

It is necessary, therefore, to check belt tension during the

first few months of operation, and to check for proper

tension weekly during the first 60 days, after which

30-day check intervals are sufficient.

CAUTION: Turn off all power to the equipment

before checking belt tensions.

CAUTION: Do not over tighten belts.

CAUTION: Do not attempt to tighten any belt or

belts by changing the pitch of an adjustable pulley.

This will change the air flow and fan speed.

Consult the factory if the fan speed must be

changed.

Suggested Belt Tension Method

1. Check tension frequently during the first 24-48

hours of run-in operation. Ideal tension is the lowest

tension at which the belt will not slip under peak load

conditions. Over tensioning shortens belt and bearing

life.

2. To properly tension a conventional V-belt drive,use the

following procedure:

a. Measure the span length.

b. At the center of the span,apply a force perpendicular

to the span to deflect the belt 1/64 inch for every

inch of span length. For example, for a 40 inch

span, apply a force that will deflect the belt 40/64

or 5/8 of an inch.

c. Compare the force you have applied with the

values given in the table below. If the force is

between the values for normal tension and 1 1/2

times normal tension, the belt tension should be

satisfactory. If the belt tension is not within this

range, it can be adjusted by loosening the motor

mounting bolts and adjusting the position of the

motor along its base.

NOTE: A new drive can be tightened to two times

the minimum value shown to allow for normal

drop in tension during the run-in period.

F. Gaskets

Gaskets are used on doors, inspection covers, some filter

racks, and some outdoor air dampers. Inspect gaskets

periodically and repair or replace as required.

G. Heater

1. At least a yearly inspection is recommended for

heating installations and more frequently for process

applications in year-round operation. Your own

experience is the best guide in determining frequency

of inspection, but as a minimum, the following

procedure should be followed:

a. Shut the system down totally, disconnecting or

locking out power supply so there can be no

accidental start-up during inspection.

b. Inspect the burner carefully, including upstream and

downstream sides of mixing plates as well as burner

body face. Note that complete burner assembly

may have to be removed for proper inspection and

cleaning. Any accumulation of scale or foreign

material on either side of the mixing plates should

be removed with a wire brush. Check visually that

no holes in the mixing plates are blocked. If any

burner ports are plugged, even partially, clear them

with a piece of wire. Consult the factory for

alternate procedures.

If any mixing plates are loose or missing fasteners,

tighten or replace as necessary. Always use zinc

plated or stainless fasteners.

The mixing plates on the burner may display

“hairline” cracks. These cracks are normal and

caused by thermal stresses occurring during com-

bustion. The presence of these “hairline” cracks in

no significant way affects the combustion efficiency

or performance of the heater. Should a large

opening develop, it may cause difficulties in cross

ignition of flame across the face of the burner. If

this does occur, the specific mixing plate or plates

involved must be replaced.

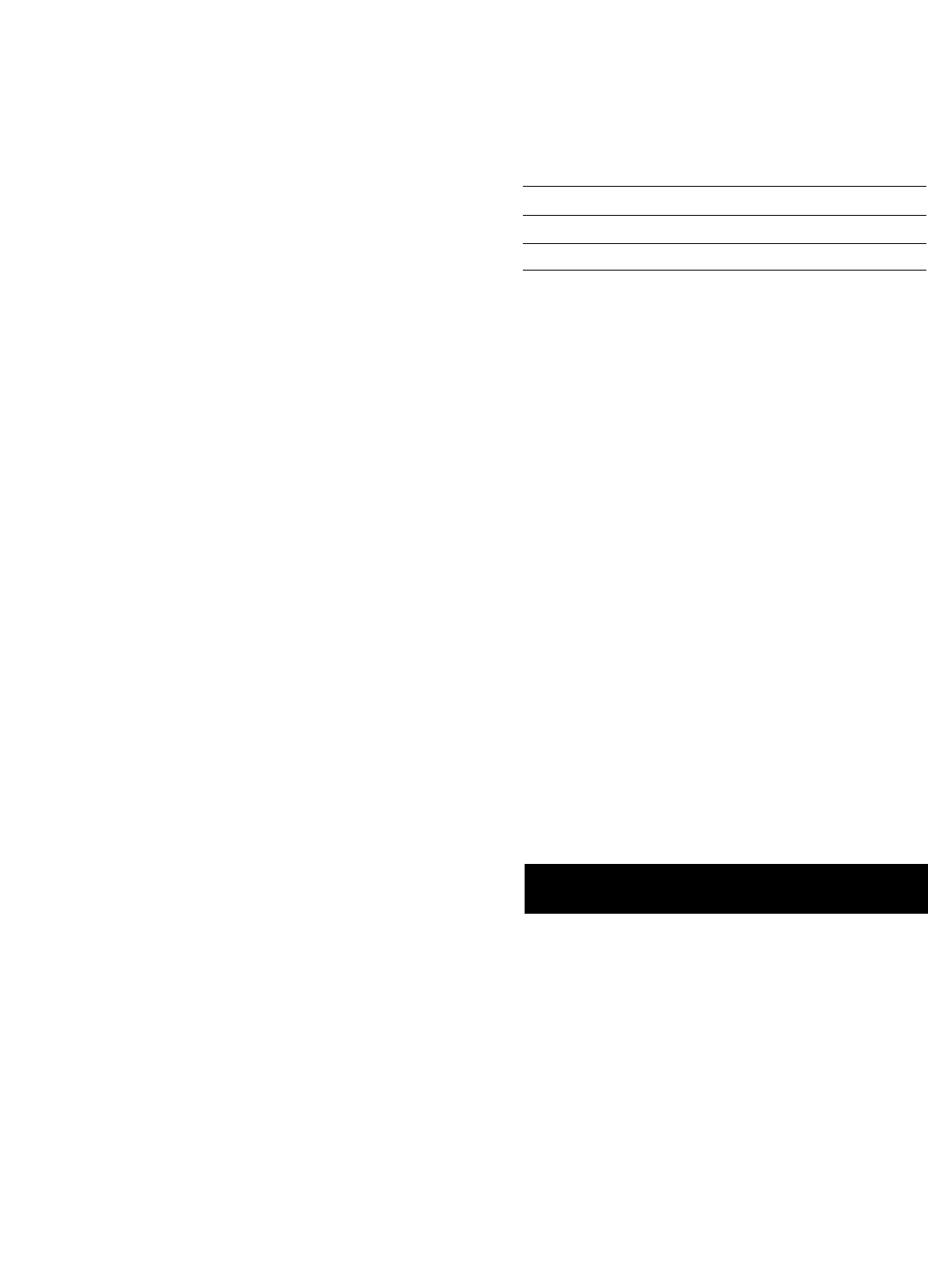

B Section

small

pulley

diameter

range in

inches

Belt

Manufacturer &

Type Belt

Pounds

Force for

Normal

Tension

Pounds

Force for

11/2 times

Normal

Tension

3.4-4.2 Gates Hi-Power 4.4 6.6

Gates Hi-Power

Gates Hi-Power

4.9 7.4

5.8 8.7

4.4-4.6

5.8-8.6

WARNING: Do not enlarge burner ports or

performance may be drastically affected.

Note: For recommendation of other types of belts, consult

respective manufacturers.