SKU 95591/95592/95593 For technical questions, please call 1-800-444-3353 PAGE 11

To clean the Impeller Cover and Impeller: 2. A clogged or dirty Impeller Cover

or Impeller (28) will greatly reduce performance of the Pump. To clean the Impel-

ler Cover (31), spray the Cover with clean water. To clean the Impeller, remove

the nine Screws (32) at the bottom of the Base (25). Then, remove the Base to

expose the Impeller Cover and Impeller. Use a stream of clean water to clean the

Impeller and Impeller area inside the Pump. Then, replace the Base. (See Assy.

Diagram.)

When nished,3. store the Pump in a clean, dry and safe location out of reach of

children. In cold weather, when the Pump is not in use, protect the interior of the

Pump from freezing by draining the water and pumping a permanent type automo-

bile anti-freeze containing a rust inhibitor through the system. A 50% mixture with

water is recommended. Be sure to ush the system with a neutralizing liquid prior

to re-use of the Pump. Note: Always properly dispose of all used anti-freeze.

CAUTION! All maintenance, service, or repairs not mentioned in this manual

must only be performed by a qualied service technician.

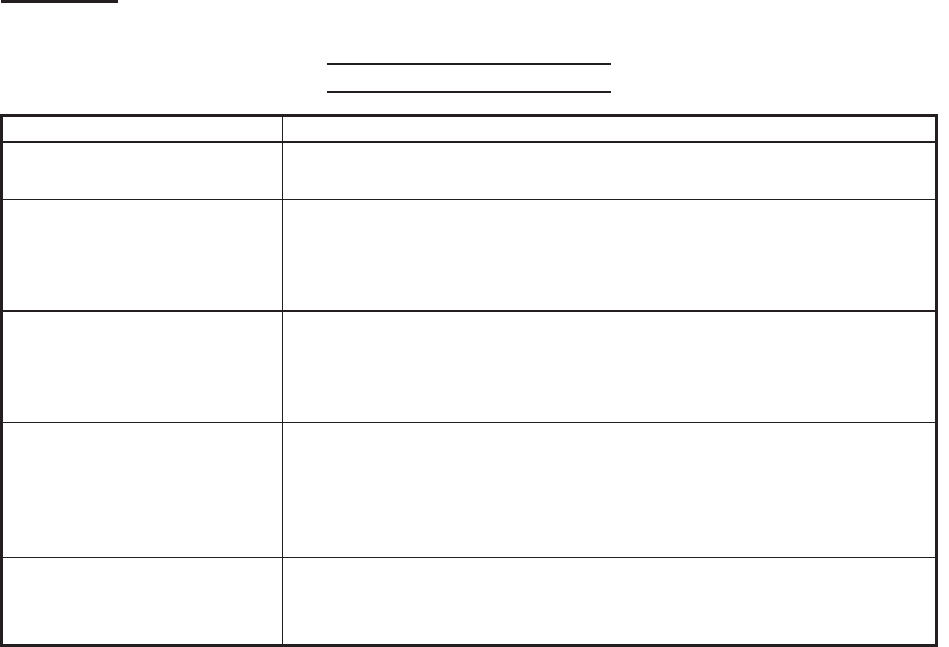

TROUBLESHOOTING

Problem Possible Solution

Pump does not start. Plug the Pump into a working, 115 volt, GFCI electrical outlet.1.

Adjust the Float Switch to a higher position.2.

No ow from the Pump. Clean Impeller and Impeller Cover.1.

Check Discharge Pipe for freezing or blockage. If necessary, thaw 2.

Pipe and/or remove excess debris.

Discharge Pipe excessively bent. Straighten Pipe.3.

Pump does not automatically

switch off.

Float Switch cannot sink down. Lower Float Switch.1.

Check for excessive debris beneath Float Switch.2.

Unplug Pump from its electrical outlet. Discontinue using Pump until 3.

a qualied service technician checks Pump for damage.

Insufcient ow. Clean Impeller and Impeller Cover.1.

Check Discharge Pipe for freezing or blockage. If necessary, thaw 2.

Pipe and/or remove excess debris. Be careful of excessive lift height.

Have a qualied service technician clean interior of Pump and, if 3.

necessary, replace worn parts.

Pump switches off too soon. Adjust the Float Switch to a higher position.1.

Clean Impeller and Impeller Cover.2.

Make sure the water temperature does not exceed 95° Fahrenheit.3.