4 Choosing the Right Chemicals for Your Minilab • J-36

CHOOSING A PAPER PROCESS

KODAK EKTACOLOR PRIME SP Developer Replenisher

is a new paper developer that is replacing the following

products:

KODAK EKTACOLOR PRIME Developer

Replenisher

KODAK EKTACOLOR PRIME Developer

Replenisher LORR

KODAK EKTACOLOR PRIME Developer

Regenerator

Because the new developer will not be available in all

regions at the same time, this publication includes

recommendations for EKTACOLOR PRIME SP Developer

Replenisher and the products it will replace.

Most minilabs have been able to use EKTACOLOR

PRIME Chemicals and realize cost savings and reductions in

processing-solution waste. EKTACOLOR PRIME SP

Developer Replenisher offers even greater advantages:

easier mixing with a single-part concentrate, further

reductions in replenishment rates and effluents for users of

EKTACOLOR PRIME Developer Replenisher, and less

packaging waste. (For information about converting, see

Converting to KODAK EKTACOLOR PRIME SP Developer

Replenisher.)

If your lab operates at low utilization or if your equipment

has a roller-transport design, KODAK EKTACOLOR RA

Developer Replenisher RT will continue to provide the best

process performance.

Before choosing a Process RA-4 cycle, it is important to

understand processor utilization and the level of operation of

your minilab paper processor.

Processor Utilization

Utilization is a way of expressing how much of your

processor’s capacity is used. If your processor utilization is

low, oxidation and evaporation will affect the activity of

your processing solutions.

The simplest way to determine your processor utilization

is to measure “tank turnovers” of your developer tank

solution. One tank turnover is the point at which the volume

of replenisher added to the tank equals the volume of the

processor tank.

EKTACOLOR PRIME SP Developer Replenisher is

designed for minilabs that have average to high utilization,

i.e., a developer tank turnover occurs at least once every four

weeks. If your paper processor operates at low utilization—

i.e., it takes longer than four weeks for a developer tank

turnover to occur—you should use KODAK EKTACOLOR

RA Developer Replenisher RT and EKTACOLOR RA

Bleach-Fix and Replenisher. These chemicals contain more

preservative and are replenished at a higher rate to minimize

the effects of low utilization.

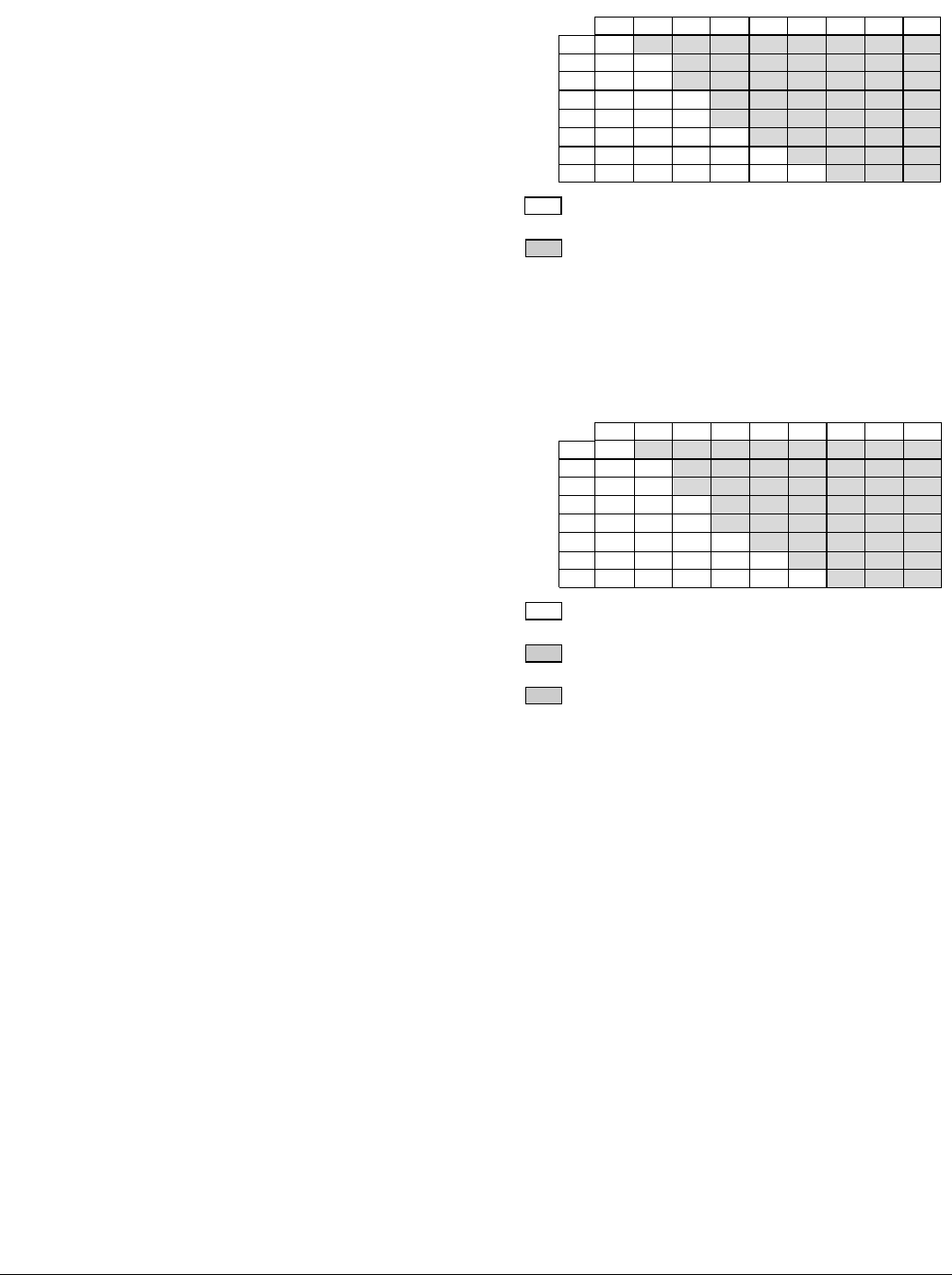

To determine the option that is suitable for your minilab,

use the information in the following charts. To use these

charts, you need to know the number of prints you process

each week. Utilization is based on a 10-percent makeover

rate and a six-day work week.

Developer Options for Process RA-4 Based on

Processor Utilization

If EKTACOLOR PRIME SP Developer Replenisher is

not yet available in your country, use the table and products

below:

Note: If you use EKTACOLOR PRIME Developer

Replenisher, use EKTACOLOR PRIME Bleach-Fix

Replenisher. If your processor operates at low utilization,

use EKTACOLOR RA Developer Replenisher RT and

EKTACOLOR RA Bleach-Fix and Replenisher.

F002_0994AC

EKTACOLOR PRIME SP Developer Replenisher (New)

40

50

EKTACOLOR RA Developer Replenisher RT

10

15

25

30

20

(102 x 152 cm)

prints per day:

Tank

(Litres)

olume

250

125

375

5

500

750

1250

1000

2500

1875

4 x 6 - inch

SP SP

SP

SP

SP

SP

SP

SP

SP

SP

SP

SP

SP

SP

SP

SP

SP

SP

SP

SP

SP

SP SP

SP

SP

SP

SP

SP

SP

SP SP

SP

SP

SP

SP

SP

SP

SP SP

SP

SP

SP

SP

SP

SP

SP

SP

F002_0938AC

EKTACOLOR PRIME Developer Replenisher

EKTACOLOR PRIME Developer Replenisher

40

50

EKTACOLOR RA Developer Replenisher RT

10

15

25

30

20

(102 x 152 cm)

prints per day:

Tank

(Litres)

Volume

250

125

375

5

**

*

500

750

1250

1000

**

*

**

2500

1875

*

*

*

*

*

*

**

*****

******

or

4 x 6 - inch

EKTACOLOR PRIME Developer Replenisher LORR

*