Choosing the Right Chemicals for Your Minilab • J-36 5

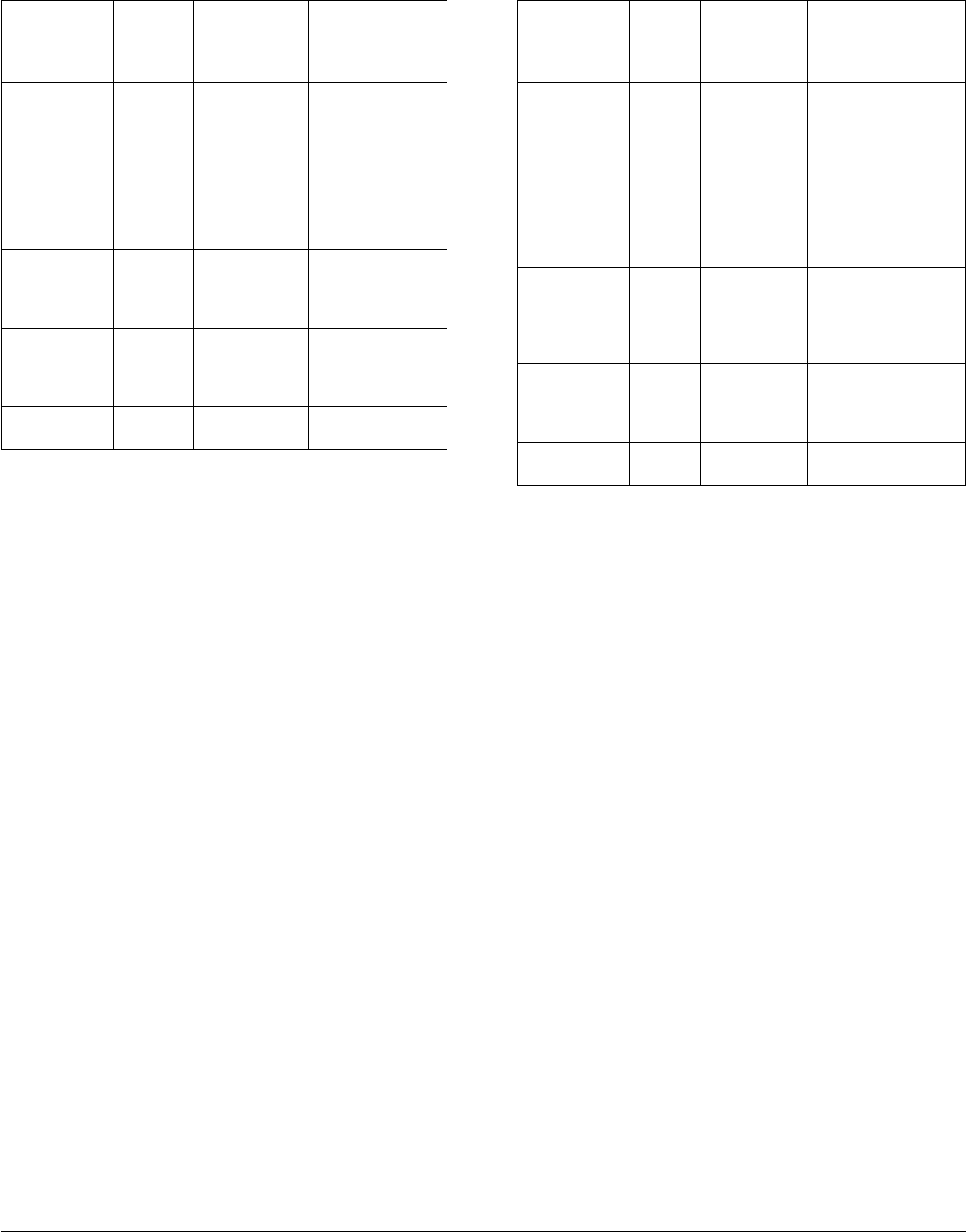

Process RA-4 Cycle—Average Utilization

This cycle is appropriate for processors with average

utilization—i.e., a developer tank turnover occurs at least

once every four weeks.

Solution/

Step

Time

*

min:sec

* Immersion time plus crossover time to the next tank. For best results,

use the recommended times with crossover times of 6 seconds or less.

Temperature

°C (°F)

Starting-Point

Replenishment

Rate

mL/m

2

(mL/ft

2

)

EKTACOLOR

PRIME SP

Developer

Replenisher

†

or

EKTACOLOR

PRIME

Developer

Replenisher

† This developer may not yet be available in your country. If not, use

EKTACOLOR PRIME Developer Replenisher in a processor with

average utilization.

0:45

37.8 ± 0.3

(100.0 ± 0.5)

108 (10)

161 (15)

EKTACOLOR

PRIME

Bleach-Fix

Replenisher

0:45

30 to 36

(86 to 97)

108 (10)

EKTACOLOR

PRIME

Stabilizer and

Replenisher

‡

‡ Use four countercurrent-flow stabilizer tanks with equal times in all

tanks (0:23 in each tank). With three countercurrent-flow tanks, use a

replenishment rate of 495 mL/m

2

(46 mL/ft

2

); with two

countercurrent-flow tanks, use 970 mL/m

2

(90 mL/ft

2

).

If your minilab uses a countercurrent-flow wash instead of a

stabilizer, use a wash-water temperature of 30 to 40°C (86 to 104°F).

For wash times of 1:30 or longer, the wash-flow rate should be

between 2160 and 10,800 mL/m

2

(200 and 1000 mL/ft

2

). The actual

rate depends on the number of tanks and the wash time (see KODAK

Publication No. Z-100, Using KODAK Chemicals in Minilabs, or Z-130,

Using KODAK EKTACOLOR RA Chemicals).

1:30

30 to 37

(86 to 99)

248 (23)

Dry

As

needed

Not over

96 (205)

Process RA-4 Cycle—High Utilization

This cycle is appropriate for processors with high

utilization—i.e., a developer tank turnover occurs at least

once every two weeks.

Solution/

Step

Time

*

min:sec

* Immersion time plus crossover time to the next tank. For best results,

use the recommended times with crossover times of 6 seconds or less.

Temperature

°C (°F)

Starting-Point

Replenishment

Rate

mL/m

2

(mL/ft

2

)

EKTACOLOR

PRIME SP

Developer

Replenisher

†

or

EKTACOLOR

PRIME

Developer

Replenisher

LORR

† This developer may not yet be available in your country. If not, use

EKTACOLOR PRIME Developer Replenisher LORR in a processor

with high utilization.

0:45

37.0 ± 0.3

(100.0 ± 0.5)

108 (10)

EKTACOLOR

RA 100

Bleach-Fix

and

Replenisher

‡

‡ This product will be renamed KODAK EKTACOLOR PRIME

Bleach-Fix Replenisher LORR.

0:45

30 to 36

(86 to 97)

54 (5)

EKTACOLOR

PRIME

Stabilizer and

Replenisher

§

§ Use four countercurrent-flow stabilizer tanks with equal times in all

tanks (0:23 in each tank). With three countercurrent-flow tanks, use a

replenishment rate of 495 mL/m

2

(46 mL/ft

2

); with two

countercurrent-flow tanks, use 970 mL/m

2

(90 mL/ft

2

).

If your minilab uses a countercurrent-flow wash instead of a

stabilizer, use a wash-water temperature of 30 to 40°C (86 to 104°F).

For wash times of 1:30 or longer, the wash-flow rate should be between

2160 and 10,800 mL/m

2

(200 and 1000 mL/ft

2

). The actual rate

depends on the number of tanks and the wash time (see KODAK

Publication No. Z-100, Using KODAK Chemicals in Minilabs, or Z-130,

Using KODAK EKTACOLOR RA Chemicals).

1:30

30 to 37

(86 to 99)

248 (23)

Dry

As

needed

Not over

96 (205)