6 Choosing the Right Chemicals for Your Minilab • J-36

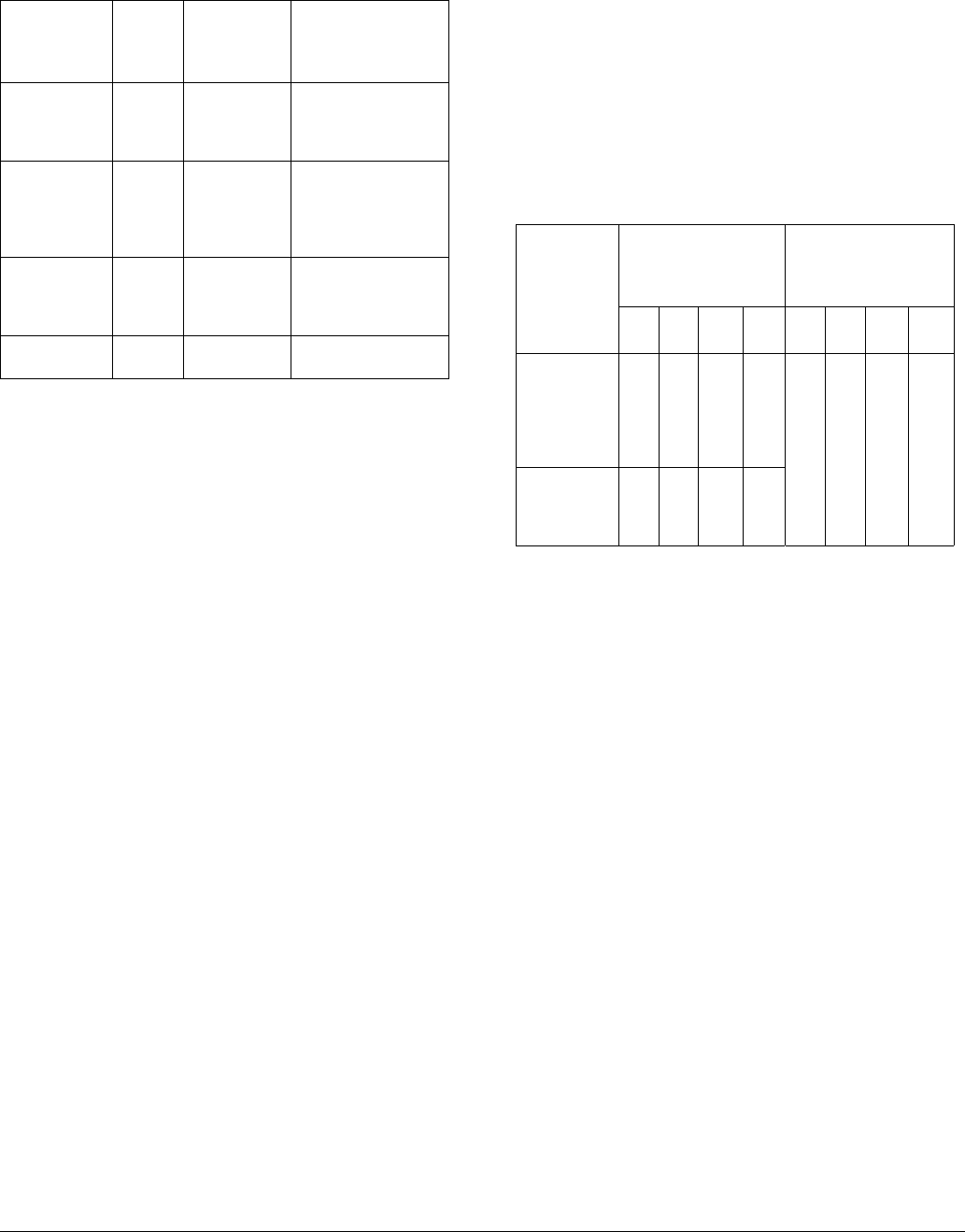

Process RA-4 Cycle—Low Utilization

This cycle is appropriate for processors with low

utilization—i.e., a developer tank turnover requires longer

than four weeks.

Solution/

Step

Time

*

min:sec

* Immersion time plus crossover time to the next tank. For best results,

use the recommended times with crossover times of 6 seconds or less.

Temperature

°C (°F)

Starting-Point

Replenishment

Rate

mL/m

2

(mL/ft

2

)

EKTACOLOR

RA Developer

Replenisher

RT

0:45

35 ± 0.3

(95 ± 0.5)

215 (20)

EKTACOLOR

RA

Bleach-Fix

and

Replenisher

0:45

30 to 36

(86 to 97)

215 (20)

EKTACOLOR

PRIME

Stabilizer and

Replenisher

†

† Use four countercurrent-flow stabilizer tanks with equal times in all

tanks (0:23 in each tank). With three countercurrent-flow tanks, use a

replenishment rate of 495 mL/m

2

(46 mL/ft

2

); with two

countercurrent-flow tanks, use 970 mL/m

2

(90 mL/ft

2

).

If your minilab uses a countercurrent-flow wash instead of a

stabilizer, use a wash-water temperature of 30 to 40°C (86 to 104°F).

For wash times of 1:30 or longer, the wash-flow rate should be between

2160 and 10,800 mL/m

2

(200 and 1000 mL/ft

2

). The actual rate

depends on the number of tanks and the wash time (see KODAK

Publication No. Z-100, Using KODAK Chemicals in Minilabs, or Z-130,

Using KODAK EKTACOLOR RA Chemicals).

1:30

30 to 37

(86 to 99)

248 (23)

Dry

As

needed

Not over

96 (205)

Converting to KODAK EKTACOLOR PRIME SP

Developer Replenisher

Before converting to EKTACOLOR PRIME SP Developer

Replenisher, use all of your current stock of EKTACOLOR

PRIME Developer Replenisher (and EKTACOLOR PRIME

Developer Regenerator) or EKTACOLOR PRIME

Developer Replenisher LORR. You do not need to dump

your current working tank solution.

When you begin to use EKTACOLOR PRIME SP

Developer Replenisher to replenish your existing developer

tank solution, adjust your replenishment rate to the

appropriate setting in the following table. If you currently

use EKTACOLOR PRIME Developer Replenisher LORR,

you do not need to adjust your replenishment rate.

Note: If your process is in control with EKTACOLOR

PRIME Developer Replenisher, you can also calculate the

replenishment rate for EKTCOLOR PRIME SP Developer

Replenisher by multiplying your current rate by 0.67. Then,

reset the rate (or pump setting) to the new rate. If you need

help adjusting the replenishment rate, contact your minilab

manufacturer.

Monitoring Your Paper Process

Use KODAK Control Strips, Process RA-4, to monitor your

paper process. Follow the procedures described in KODAK

Publication No. Z-100, Using KODAK Chemicals

in Minilabs, or Z-130, Using KODAK EKTACOLOR RA

Chemicals.

Current

Developer

Solution

Current

Replenishment Rate

Replenishment Rate

with PRIME SP

Developer

Replenisher

mL/

m

2

mL/

ft

2

mL/

m

*

* Normally, mL per linear metre of paper 127 mm (5 in.) wide.

mL/

ft

†

† Normally, mL per linear foot of paper 127 mm (5 in.) wide.

mL/

m

2

mL/

ft

2

mL/

m

*

mL/

ft

†

PRIME

Developer

Replenisher

and

Developer

Regenerator

161 15 20.5 6.3

108 10 13.7 4.17

PRIME

Developer

Replenisher

LORR

108 10 13.7 4.17