2-2

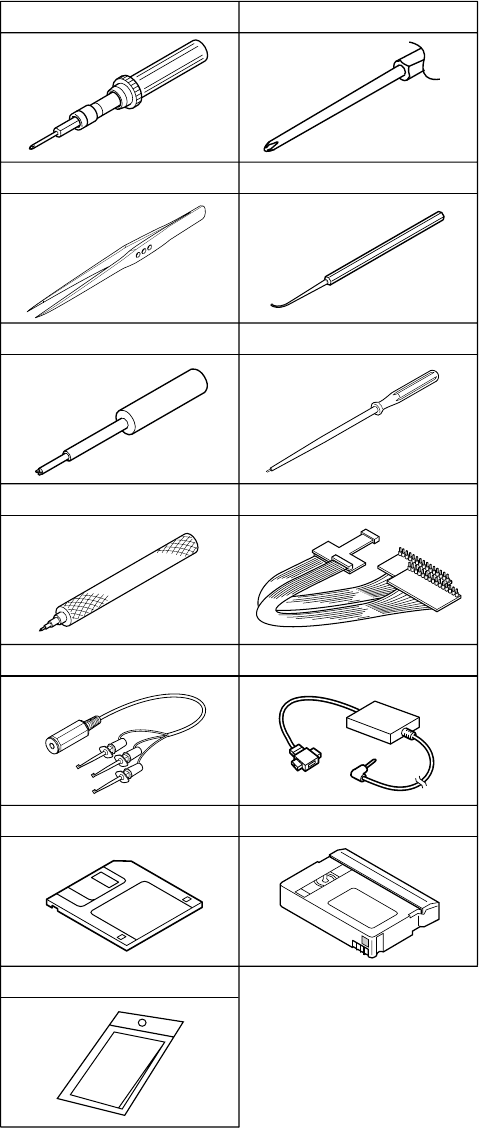

2.2 JIGS AND TOOLS REQUIRED FOR DISASSEMBLY,

ASSEMBLY AND ADJUSTMENT

2.2.1 Tools required for adjustments

1. Torque Driver

Be sure to use to fastening the mechanism and exterior

parts because those parts must strictly be controlled for

tightening torque.

2. Bit

This bit is slightly longer than those set in conventional

torque drivers.

3. Tweezers

To be used for removing and installing parts and wires.

4. Chip IC replacement Jig

To be used for adjustment of the camera system.

5. Guide Driver

To be used to turn the guide roller to adjustment of the

linarity of playback envelope.

6. Adjustment Driver

To be used for adjustment.

7. Slit washer Installation Jig

To be used to install slit washers.

8. Jig Connector cable

Connected to CN105 of the main board and used for

electrical adjustment, etc.

9. Communication cable

Connect the Communication cable between the PC ca-

ble and Jig connector cable when performing a PC ad-

justment.

10. PC cable

To be used to connect the VideoMovie and a personal

computer with each other when a personal computer is

used for adjustment.

11. Service Support System

To be used for adjustment with a personal computer.

12. Alignment Tape

To be used for check and adjustment of interchange-

ability of the mechanism.

13. Cleaning Cloth

Recommended cleaning cloth to wipe down the video

heads, mechanism (tape transport system), optical lens

surface.

Torque Driver

YTU94088

1

Bit

YTU94088-003

2

3

Chip IC Replacement Jig

PTS40844-2

4

Guide Driver

YTU94148A

5

Adjustment Driver

YTU94028

6

Slit Washer Installation Jig

YTU94121A

7 8

Jig Connector cable

YTU93082C

9 10

Communication cable

YTU93107A

11

PC cable

QAM0099-002

12

Alignment Tape

MC-1

13

Service Support System

YTU94057-57

Cleaning Cloth

KSMM-01

Tweezers

P-895

Table 2-2-1