Maintenance

4-4

DPO4000 Series Service M anual

To access the inside of the oscilloscope for inspection and cleaning, refer to the

Removal Procedures in this section.

Inspect the internal portions of the oscilloscope for damage and wear, using

Table 4--2 as a guide. Repair any defects immediately.

If any circuit board is repaired or replaced, check Table 4--2 to see if it is

necessary to adjust the oscilloscope.

CAUTION. To prevent damage from electrical arcing, ensur e that circuit boards

and components are dry before applying power to the oscilloscope.

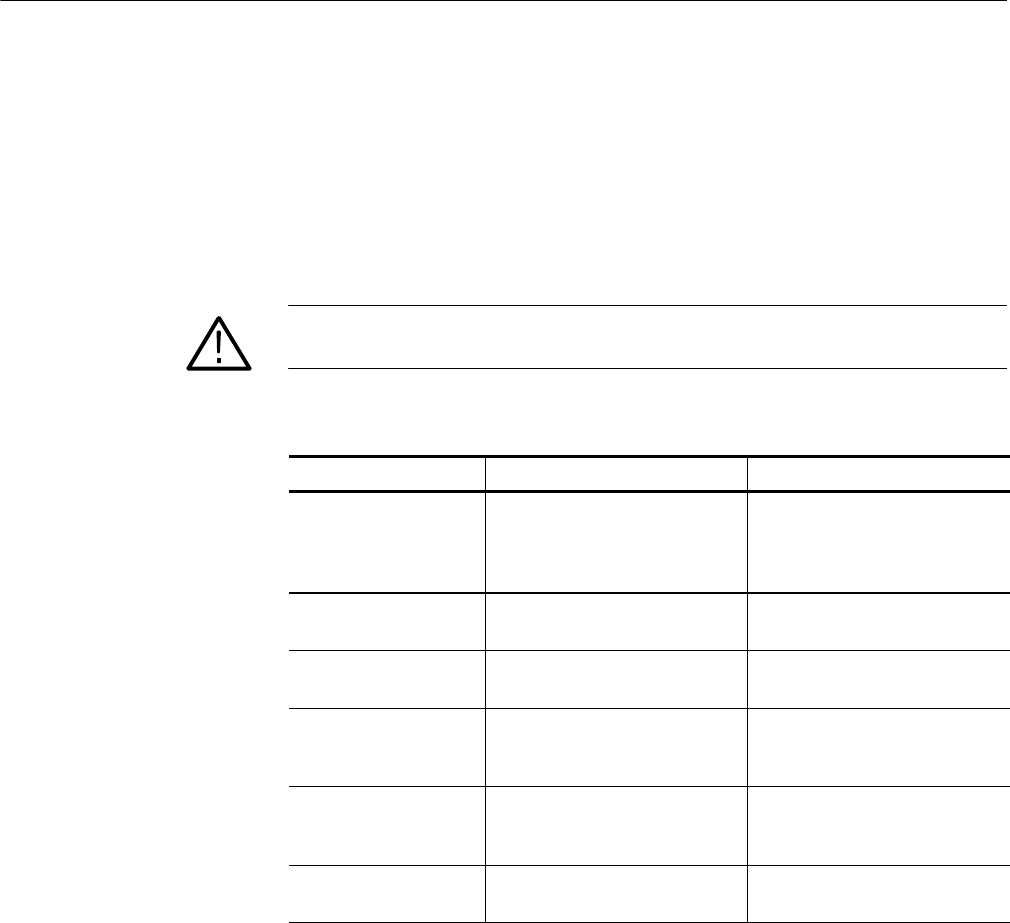

Table 4- 2: Internal inspection check list

Item Inspect for Repair action

Circuit boards Loose, broken, or corroded

solder connect ions. Burned

circuit boards. Burned, broken, or

cracked circuit -run pl ating.

Remove and replace damaged

circuit board.

Resistors Burned, cracked, broken, blis-

tered condition.

Remove and replace damaged

circuit board.

Solder connect ions Cold solder or rosin joints. Resolder joint and clean with

isopropyl alcohol.

Capacitors Damaged or leaking cases.

Corroded solder on leads or

terminals.

Remove and replace damaged

circuit board.

Wiring and cables Loose plugs or connectors.

Burned, broken, or frayed wiring.

Firmly seat connectors. Repair or

replace m odules with def ective

wires or cables.

Chassis Dents, deformations, and dam-

aged hardware.

Straight en, repair, or replace

defective hardware.

Interior Inspection