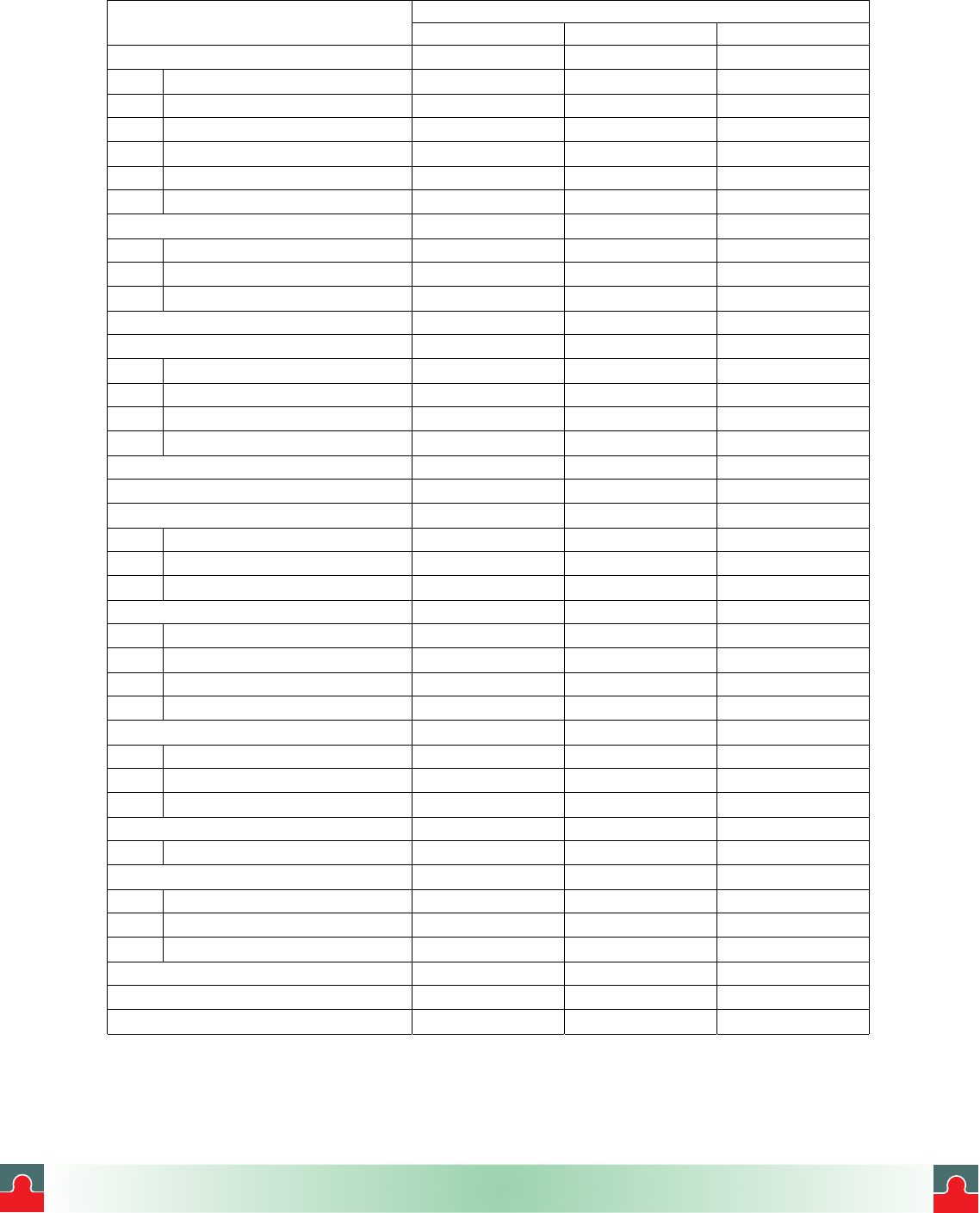

Table 1. Emissivity Values for Metals

Material Emissivity

1.0µm 1.6µm 8-14µm

Aluminum

Unoxidized 0.1-0.2 0.02-0.2 n.r.

Oxidized 0.4 0.4 0.2-0.4

Alloy A3003,

Oxidized n.r. 0.4 0.3

Roughened 0.2-0.8 0.2-0.6 0.1-0.3

Polished 0.1-0.2 0.02-0.1 n.r.

Brass

Polished 0.8-0.95 0.01-0.05 n.r.

Burnished n.r. n.r. 0.3

Oxidized 0.6 0.6 0.5

Chromium 0.4 0.4 n.r.

Copper

Polished n.r. 0.03 n.r.

Roughened n.r. 0.05-0.2 n.r

Oxidized 0.2-0.8 .2-0.9 0.4-0.8

Electrical Terminal Blocks n.r. n.r. 0.6

Gold 0.3 0.01-0.1 n.r.

Haynes Alloy 0.5-0.9 0.6-0.9 0.3-0.8

Inconel

Oxidized 0.4-0.9 0.6-0.9 0.7-0.95

Sandblasted 0.3-0.4 0.3-0.6 0.3-0.6

Electropolished 0.2-0.5 0.25 0.15

Iron

Oxidized 0.4-0.8 0.5-0.9 0.5-0.9

Unoxidized 0.35 0.1-0.3 n.r.

Rusted n.r. 0.6-0.9 0.5-0.7

Molten 0.35 0.4-0.6 n.r.

Iron, Cast

Oxidized 0.7-0.9 0.7-0.9 0.6-0.95

Unoxidized 0.35 0.3 0.2

Molten 0.35 0.3-0.4 0.2-0.3

Iron, Wrought

Dull 0.9 0.9 0.9

Lead

Polished 0.35 0.05-0.2 n.r.

Rough 0.65 0.6 0.4

Oxidized n.r. 0.3-0.7 0.2-0.6

Magnesium 0.3-0.8 0.05-0.3 n.r.

Mercury n.r. 0.05-0.15 n.r.

Molybdenum

July 1, 2003 - 68 - Version 1.0

i

i

Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796