13

Spindle Brake

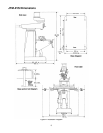

The spindle brake lever is located on the upper left

side of the mill head (Figure 8). Pull lever downward

to apply the brake. The spindle brake lever is used

only after the motor switch has been set to OFF. The

spindle will not stop with the motor running.

Figure 8

High-Neutral-Low Shift Lever

The mill head can be driven directly (High Speed) or

through the back gear (Low Speed) in the mill head.

The selection is made by changing the position of the

shift lever.

The shift lever is located at the lower right side of the

mill head (Figure 9). The lever position closest to the

operator is the High setting. The lever position away

from the operator is the Low setting. The middle

position is the Neutral setting.

Do not shift the High-Low Gear

Lever while the motor is

running. Rotate the spindle by hand to facilitate

changing lever positions.

Figure 9

Quill Power Feed Lever

Do not use power feed at speeds

above 3000 R.P.M.

It is recommended to disengage

the power feed worm gear

whenever the power feed is not required. This

avoids unnecessary wear on the worm gear.

Do not move the Quill Power

Feed Lever unless the motor is

at a complete stop. When changing the lever

position, do it gently. If the gear does not engage,

jog the motor and allow it to stop before

attempting to change.

The quill power feed lever is located on the right side

of the mill head (Figure 10). It is used to engage and

disengage the quill power feed mechanism.

The power feed is engaged by pulling out the knob

and rotating the handle to a new locked position.

When engaged, the power feed mechanism will drive

the spindle upward or downward. The power feed

mechanism will not drive the spindle when the handle

is in the disengage position.

Figure 10

Feed Rate Lever

The Feed Rate Lever (Figure 11) is used to set the

per-revolution rate of the power feed mechanism.

Three feed rates are available: 0.0015-inch, 0.003-

inch, and 0.006-inch per revolution. The positions are

shown on an indicator plate under the feed rate lever.

The rate is selected by pulling out the knob on the

feed rate lever and moving the handle to the detent of

the desired feed rate.

Note: The knob is spring loaded – pull out to rotate to

new position.

Unlike other controls on the machine, the lever shifts

into engagement more easily with the motor running,

and the quill feed lever engaged.

Figure 11