21

Maintenance

Before any intervention on the machine, disconnect it from the electrical supply by

pulling out the plug or switching off the main switch! Failure to comply may cause serious injury.

Lubrication

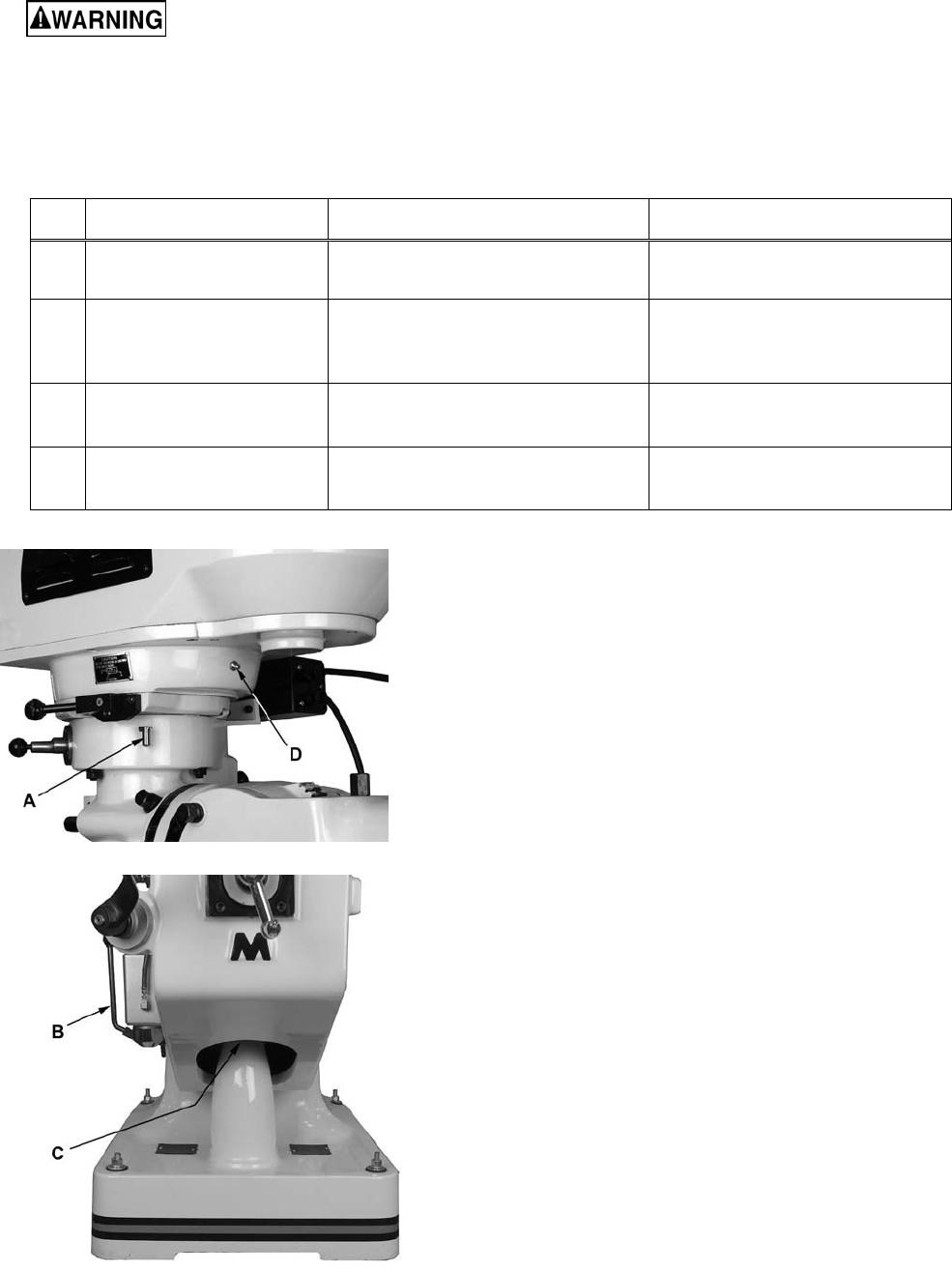

The milling machine is equipped with a “one-shot” lubrication system. The system lubricates the lead screws

and ways. An oil cup and grease nipple on the mill head provide lubrication for the spindle bearings and back

gear mechanism. Refer to Figures 28 and 29 for lubrication requirements and access points.

Key Description Recommended Lubricant Action

A Spindle bearing oil cup Mobil DTE Oil Light, or equivalent Service daily.

B One-shot lube system Mobil Vactra Oil #2, or equivalent

Check oil daily – add if required.

Pull lube handle every hour

during operations.

C

Knee leadscrew grease

nipple

Mobilith AW2, or equivalent Service once each week.

D Back gear grease nipple Mobilith AW1, or equivalent

Service weekly when operating

in back gear mode.

Figure 27: Lubrication Points

Figure 28

Figure 29

Periodic Maintenance Requirements

During operation, periodically vacuum and brush

chips and debris from machine.

Periodically operate knee and table lead screws

through full range of movement to evenly distribute

lubricant (particularly when applied using the “one-

shot” system).

Periodically apply light machine oil to work table and

other exposed metal surfaces to prevent rust or

corrosion.

Periodically remove vent panels to check pulleys

and belts for unusual wear or grooving. NOTE:

Operators should vary speed occasionally to prevent

formation of grooves on the pulley surfaces.