17

4. Before applying final torque, check to make sure

the mill head is perpendicular to the worktable.

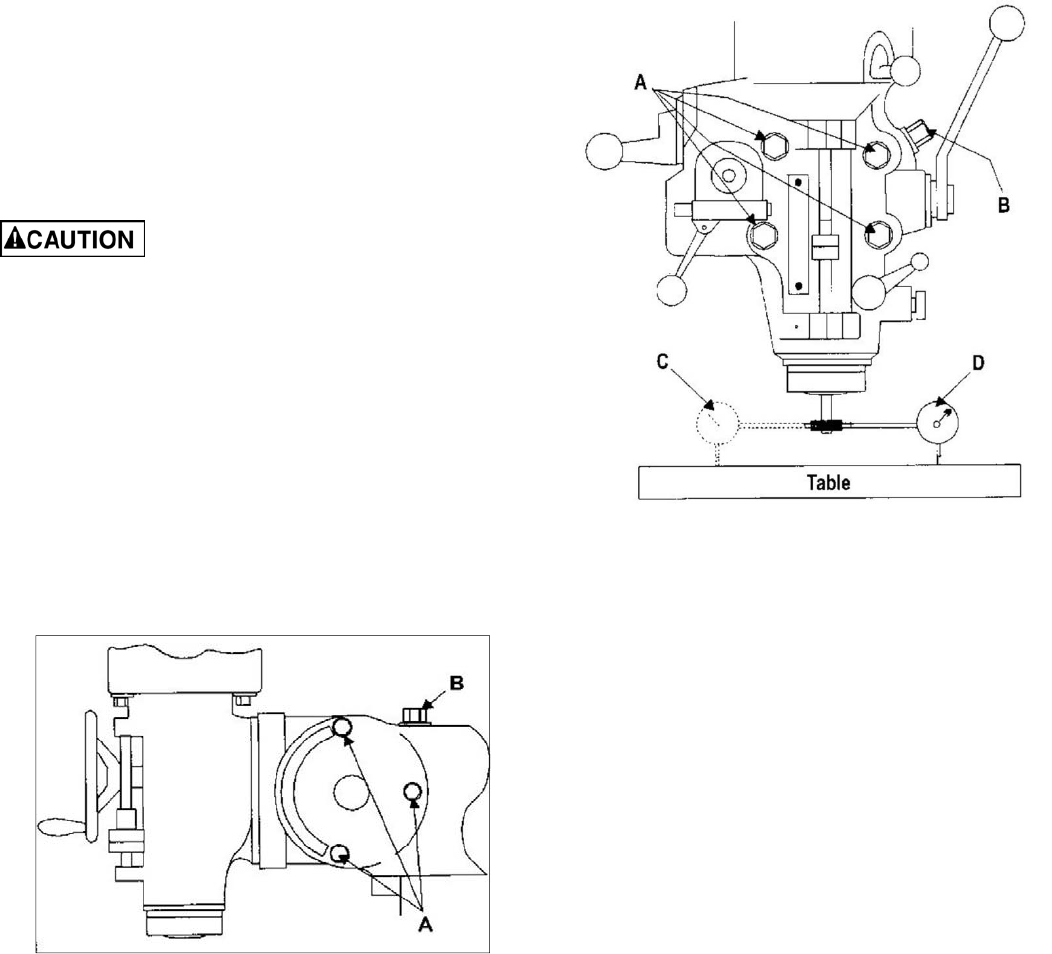

5. Set up a dial indicator in a collet and secure

using the draw bar (refer to Figure 22).

6. Put the spindle drive in neutral.

7. Set the dial indicator plunger on the worktable.

Zero the indicator.

8. Rotate the spindle 180 degrees (when rotating,

raise the dial indicator plunger by hand to prevent

it from dropping into the table T-slots).

9. Read the dial indicator. The indicator should read

zero. If not, loosen the four hex nuts and

reposition the mill head.

10. Recheck perpendicularity using the dial indicator.

Repeat the procedure above until the dial

indicator reads zero in both positions.

Be sure to apply torque in two

steps using a crossing pattern. Failure to do so

could distort the face of the ram adapter.

11. Tighten the four hex nuts. Tighten in two steps

using a calibrated torque wrench. Use a crossing

pattern to tighten the nuts. Tighten initially to 25

foot-pounds, then tighten to a final torque of 50

foot-pounds.

Mill Head – Fore/Aft Adjustment

1. Setting the angle:

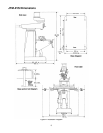

a. Loosen the three ram adapter clamp bolts on

the ram (A, Figure 21). There is no need to

loosen the bolts more than 1/2 turn to allow

tilting.

Figure 21

b. Support the mill head with your free hand.

Press upward on the spindle when changing the

angle.

c. Turn the ram adapter worm nut (B, Figure 21)

to tilt the head forward and backward. Use the

scale on the ram adapter to locate the desired

angle.

2. Returning to upright position:

a. When returning the mill head to its full upright

position, be sure to support the head by upward

pressure on the spindle as you turn the worm nut.

b. Check to make sure the mill head is perpen-

dicular to the worktable.

c. Set up a dial indicator in a collet and secure

using the draw bar (refer to Figure 22).

Figure 22

d. Put the spindle drive in neutral.

e. Set the dial indicator plunger on the worktable.

Zero the indicator.

f. Rotate the spindle 180 degrees (when rotating,

raise the dial indicator plunger by hand to prevent

it from dropping into the table T-slots).

g. Read the dial indicator. The indicator should

read zero. If not, loosen the four hex nuts and

reposition the mill head.

h. Recheck perpendicularity using the dial

indicator. Repeat the procedure above until the

dial indicator reads zero in both positions.

i. When the indicator reads zero, tighten the ram

adapter clamp bolts.