15

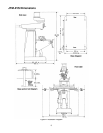

Depth Scale and Stop

Referring to Figure 15:

The Depth Scale and Stop are used in drilling

operations to set the depth of the drilled hole. The

depth scale is located on the front of the mill head.

The scale consists of a Micrometer Adjusting Nut (A),

Lock Nut (B), Quill Stop (C), Quill Stop Screw (D),

and Scale (E).

The Micrometer Adjusting Nut is set to the desired

dimension and locked in place using the Lock Nut.

The quill stop provides a positive stop for quill travel.

The graduations on the micrometer nut are in

0.001-inch increments. Adjustment of quill travel is

made by rotating the micrometer nut.

Figure 15

Power Feed Operation

The Feed Trip Adjustment sets the point at which the

quill will reset during Power Feed.

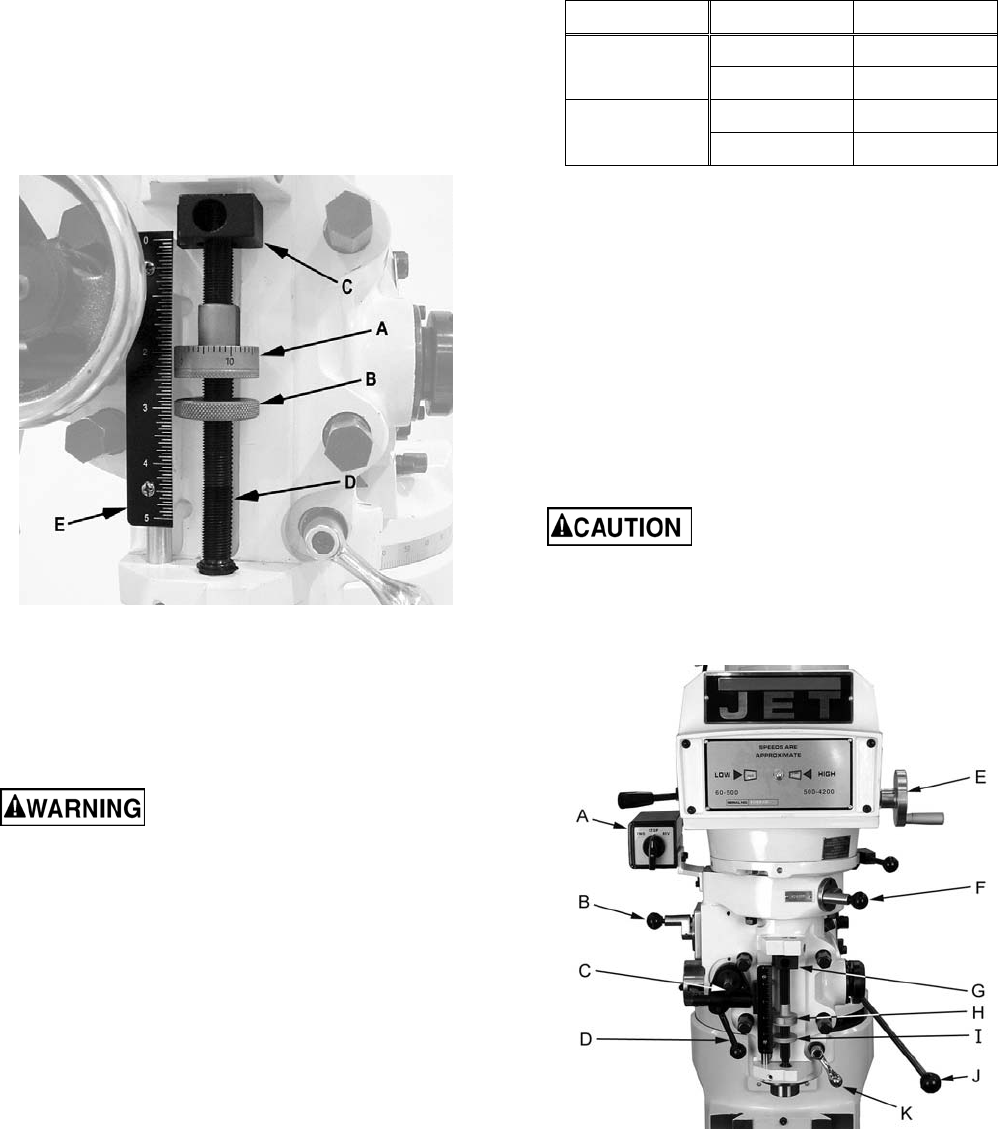

Referring to Figure 17:

Be sure that the Manual Fine

Feed Handwheel is removed.

Failure to comply may cause serious injury.

1. Loosen the Locknut (I).

2. With the Quill Feed Handle (J), advance the quill

to the point where the feed should stop.

3. Engage the Feed Trip Cam Lever (D) by pulling

away from head assembly.

4. Adjust Micrometer Adjusting Nut (H) against

Quill Stop (G).

5. Continue turning the Micrometer Adjusting Nut

(H) until the Feed Trip Cam Lever (D) trips.

6. Tighten the Locknut (I).

7. Ensure Quill Lock (K) is disengaged by rotating

counter-clockwise.

8. Start the spindle (A):

9. Select feed rate with the Variable Speed Control

Handwheel (E).

10. Set the Feed Rate Lever (B) to the feed rate

required for the tooling and material required.

11. Place the Quill Feed Engagement Lever (F) in

the Engaged position.

12. Select feed direction by setting the Feed

Direction Knob (C) position per the table:

Spindle Dir. Feed Dir. Knob Pos.

CW

Down In

Up Out

CCW

Down Out

Up In

Figure 16

13. Engage the Feed Trip Cam Lever (D) by pulling

away from head assembly.

Note: Due to variables in tool diameter, coatings,

coolant, and materials, no specific spindle speed or

feed rate recommendations are provided. Use

general shop manuals that have data applicable to

the milling and drilling operations being performed.

Or, contact the supplier of the tooling, coolant, and

material for specific recommendations.

IMPORTANT: The power feed can be used for drills

up to 3/8” in diameter (mild steel). Use manual feed

for drills larger than 3/8”.

The overload clutch is factory set

to hold up to 200 lbs. downfeed pressure on the

quill (accommodates drills up to 3/8”). Do not

attempt to adjust clutch pressure.

Figure 17