12 RT-PRC005-EN

MA'

MA'

SA'

SA'

RA'

RA'

OA

OA

OA

OA

RA'

68°F DB,

67°F WB

75°F DB,

52% RH

MA' 72.2°F DB

65°F WB

SA'

47°F DB

SA

SA

REHEAT

SA

73°F DB

Selection

Procedure

Dehumidification Selection

Typical 10 ton THC120A

2000 cfm Total Supply airflow

800 cfm Outside Air (40%)

1200 cfm Return Air

0.41” External Static Pressure

OA Conditions

Part load day and raining

68°F db

67°F wb

RA’ conditions

75°F db

63°F wb

Step 1: Determine the mixed/

entering air condition (MA’)

MA’ = (% outside air*outside air dry-bulb

temperature) + (% return air*return air

dry-bulb temperature)

MA’ = (0.40*68°F) + (0.60*75°F)

MA’ = 72.20°F db

Note: Repeat for wet-bulb

temperature (wb).

Plot on psychrometric chart.

MA’

72.2°F db

65°F wb

Step 2: Determine leaving

unit

temperature

Leaving Unit Temperature = SA’

Utilize the TOPSS™ program to

determine the leaving unit temperature.

45°F db

44°F wb

43°F dp

Step 3: Determine reheat

temperature rise

Go to PD-78 for reheat temperature rise:

26.7°F db

Note: Reheat temperature rise is based

on supply airflow and leaving evaporator

coil temperature.

Step 4: Determine leaving unit

temperature

Reheat temperature (obtained in step 3)

+ SA’

26.7°F db + 47°F = 73.7°F db

SA=73.7°F

Consider Chart C-1. If the space relative

humidity is equal to or above the space

relative humidity setpoint, the

Dehumidification Option will:

• Energize compressor or both

compressors (2 stage compressor units).

• Hot gas reheat valve is energized and

hot gas is diverted to the reheat coil.

• Dehumidification/reheat is terminated

when space humidity is reduced to 5%

below relative humidity setpoint.

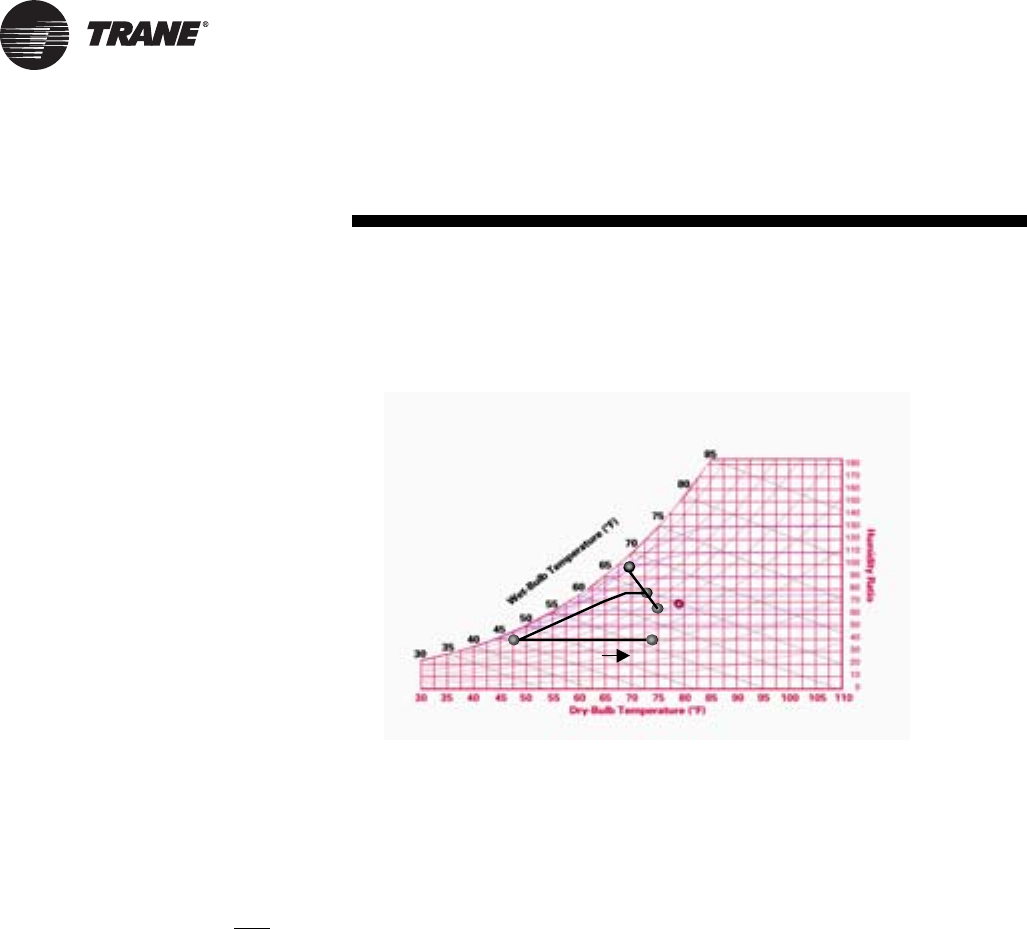

At MA’, air enters the RTU. The RTU filters,

cools, and dehumidifies the air as it

moves through the evaporator coil. Air

leaves the evaporator coil saturated at

the preset dew point condition (SA’) and

is reheated by the hot gas reheat coil to

deliver 73.7°F (SA) supply air to the

space.

Chart C-1

Step 5: Determine static pressure

drop add for reheat

Table PD-73 shows a static pressure drop

of 0.09” wc 0.41”+ 0.09” = 0.5” wc

Table PD-65 indicates that a standard

motor and field installed low static drive

kit is needed for this airflow and static

pressure range.