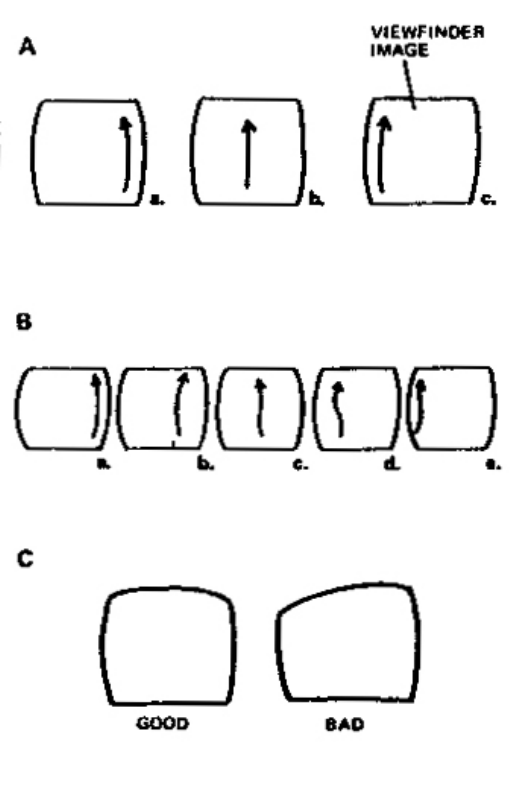

Figure 3-15 Identifying distorted mirrors

3. Concave Mirror Distortion Check

a. Focus on a target which presents a clear

vertical line (for example a door frame).

b. Scan the camera horizontally.

c. If the mirror is not distorted, the vertical line

seen in the eyepiece will vary at the camera is

scanned. At either side of the eld, the line will

be bent while in the center of the eld, the line

will be straight (see Figure 3-15 A).

d. If the mirror is distorted, the vertical lines

change more graphically as the image si

scanned and one or several reversals of direction

of bending may occur (Figure 3-15 B).

e. A telephone directory page at a distance of

2 feet may be used to check distortion. The

white pages have high contrast, ne detail and

uniform printing.

f. The frame around the viewnder may appear

non-sysmmetrical about the vertical axis. A

normal mirror will appear to be sysmmetrical

about the axis (Figure 3-15 C).

4. Fresnel Quality Check

The Fresnel screen must be examined for

blemishes, shadows, dirt, scratches, etc. A

standards chart (Figure 3-16) is available for

determining whether the Fresnel being examined

is acceptable. Focus the camera to 10.4’’for

viewing the chart.

a. First, view the Fresnel against the background

presented in Section I of the chart. Note whether

the defects (dirt, scratches, digs, etc.) are in the

A or B aera of the Fresnel.

b. Nest, compare any boot or mirror marks on

the Fresnel with the marks shown in Section II

of the chart. If the mark exceeds that shown on

the chart, the Fresnel is not acceptable.

c. View the Frenel screen against the background

of Section III on the chart. The conditions shown

on the chart are the maximum acceptable

limits for Fresnel defects. If the Fresnel being

examined has defects which go beyond those

shown on the chart, reject the Fresnel. (Note

that an illustrated listing on the chart is available

for comparison to Fresnel which have only one

or two blemishes.

d. Examine any shading on the Fresnel against

the limits shown in Section IV of the chart. If

the shading extends beyond the aera (top or

bottom of the Fresnel) shown on the chart, the

Fresnel si not acceptable.

e. Examine teh split image circle by comparong

it against teh examples shown on the chart. If

the shading on the split is greater than shown or

if there is more than one dig, pit, stain, or scratch

on the split, the Fresnel is not acceptable. the

Fresnel must also be rejected if the blemish on

the split is larger than any shown on the chart.

5. Collimation

For the collimation procedure, refer to paragraph

D «Test Equipment Operation».

The following charts should be used to identify

and correct faulty camera operation. It will

seldom be necessary to consult every chart. Only

those related to a particular malfunction should

be consulted. In some cases, the customer’s

complaint will be sufciently specic to lead you to

a particular chart. In other cases, the preliminary

inspection procedure at the beginning of this

section will provide usefull information to lead

E. USE OF ANALYSIS CHARTS