MIC400 Series Camera | Installation and Operation Manual AAAEN | 13

Bosch Security Systems Issue 1

Earthing of the MIC400 camera

1. The camera module & housing are electrically isolated so the housing

should be safety earthed regardless. The safety earth should be a bonding

connection to the cameras outside case for example one of the securing

bolts.

2. The camera should be earthed at one point only to prevent earth loops &

thus hum bars showing on the control room monitor.

3. If the system is copper throughout & the camera pictures are fed back to

the control room coaxial copper cable, then the camera should be earthed

at the video termination point in the control room & nowhere else. In this

case the PCB “Earth Link” should be broken.

4. If the video is transmitted back to the control room via some non electrical

connecting medium, e.g. fibre optic, radio or microwave link, then the

camera should be earthed at the transmitter point in the psu. The PSU

“Earth Link” may be used for this purpose.

5. If dual earthing is unavoidable then a video isolation transformer should be

fitted between the two earths.

Lightning Protection

If the camera is fitted in a highly exposed place then consideration should be given

to lightning protection. A good earth bonding connection to the case itself will

provide protection against damage from secondary strikes.

Where there is a risk of a primary strike hitting the camera housing directly, it is

recommended that a separate lightning conductor be fitted within 0.5m of the

camera and at least 1.5m higher than the camera.

The construction of the housing itself is very capable of coping with secondary

strikes and no damage to the internal electronics or camera should result if correct

lightning protection is applied.

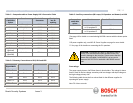

Underwater Installation

The MIC400 series are IP68 rated units, excepting the MIC400PA speakers which

are IP67, this allows complete submersion in water to a depth of 1M. The

MIC400UL and MIC400UT models allow submersion to a maximum depth of 25M

due to the special seals fitted to these models.

Typically the MIC400UL an MIC400UT are mounted inverted on a Deep Conduit

Adaptor fitted to the base, additional sealant or gaskets are applied to the joint of

the camera foot and the Deep Conduit Adaptor to ensure a watertight seal.

A suitable waterproof conduit gland and conduit is then used to carry the

composite cable to the surface for installation in the power supply. Wall Mount

Brackets (MIC-WMB) can also be used to mount the MIC400 underwater following

the same precautions as outlined above.

CAUTION: If the camera is mounted ball down it is

essential that the connector and base area of the

camera are completely sealed from water ingress.

CAUTION: Any water getting into the connector is

liable to cause corrosion to the connector pins leading

to unreliable operation of the camera unit.

CAUTION: To prevent water penetrating the composite

cable connector threads, the 25mm thread should be

sealed at final installation using PTFE tape.

Alternatively a suitable sealant may be liberally applied

to the thread prior to final tightening.

CAUTION: It is the responsibility of the installer to ensure

the correct water proof conduit glands, conduit and

gaskets/sealants are used for the installation to ensure no

water enters the cameras base and reaches the composite

cable connector. Failure to ensure a water free connector

will lead to corrosion of the camera connecter and to

camera failure. Care must also be taken to ensure that any

sealants used are non toxic to marine life.