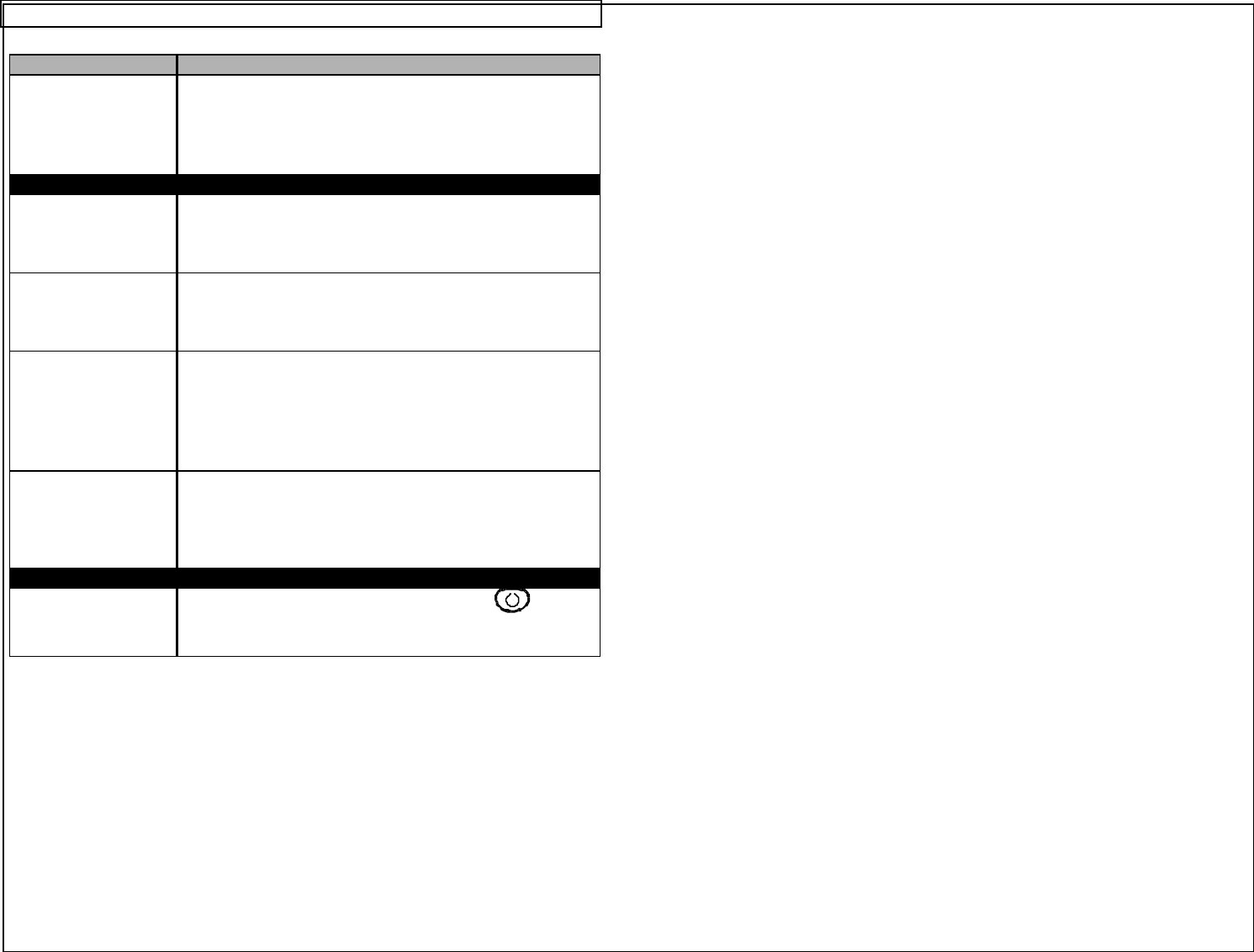

PRINTER TROUBLESHOOTING

59

SYMPTOM ACTION

Die-cut labels

continue to feed

without stopping.

• Label sensor is dirty or obstructed. Clean sensor

with soft-stemmed swab and isopropyl alcohol or

compressed air.

• Width guide is loose. Make sure the width guide

is properly located and fixed in place.

BAR CODES

Poor edge

definition (bar

codes and

alphanumerics).

• Ribbon and media are incompatible. Test

alternative ribbon or media. See compatibility

chart on page 14.

Bar codes

smearing (bar code

edges “bleeding” or

“feathering”.

• Print head heat setting is too high. Reduce heat

setting until bar edges are clean. See procedure

on page 46.

Bars in bar codes

are too wide or too

narrow resulting in

a poor scan grade.

• Print head heat setting it too high/too low. Adjust

to optimize average bar growth (visually or with

verifier). See procedure on page 46.

• Overburn (too much ribbon transfer). Reduce

print head heat setting. See procedure on page

46.

Insufficient print

contrast: Bars are

not dark enough,

spaces are not light

enough.

• Print head heat setting is too low. Increase print

head heat setting. See procedure on page 46.

OTHER

Printer Locked Up

With printer OFF, Press and hold [R] and to

RESET the printer.

Note: Saved Label files will NOT be lost during reset.