Instruction Manual

748467-A

January 2002

1-4 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Model MicroCEM

Opto-Pneumatic Method

In the opto-pneumatic method, a thermal

radiator generates the infrared radiation

which passes through the chopper wheel.

This radiation alternately passes through

the filter cell and reaches the measuring

and reference side of the analysis cell

with equal intensity. After passing another

filter cell, the radiation reaches the pneu-

matic detector.

The pneumatic detector compares and

evaluates the radiation from the measur-

ing and reference sides of the analysis

cell and converts them into voltage sig-

nals proportional to their respective inten-

sity.

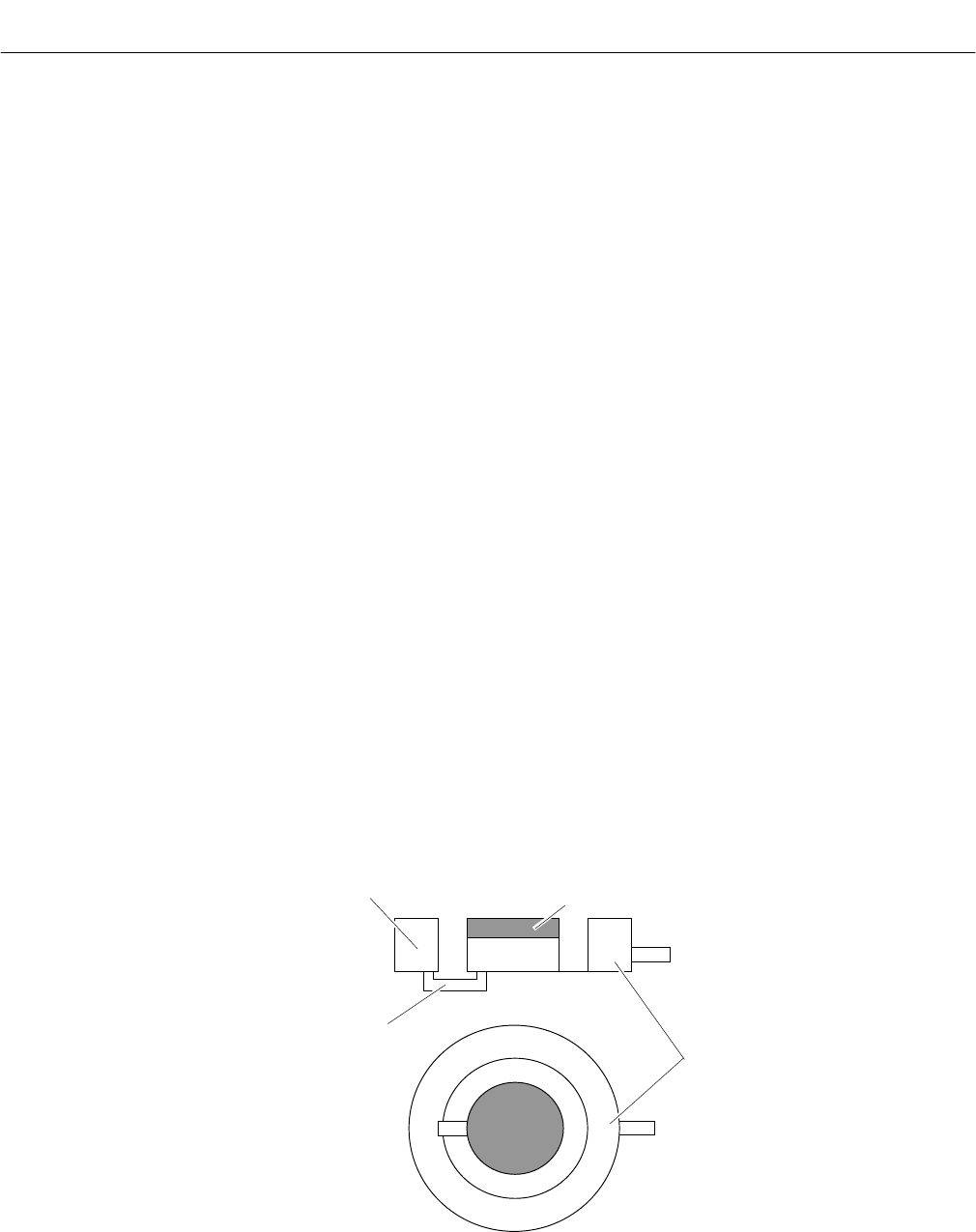

The pneumatic detector consists of a gas-

filled absorption chamber and a compen-

sation chamber which are connected by a

flow channel in which a Microflow filament

sensor is mounted. This is shown in Fig-

ure 1-2.

In principle the detector is filled with the

infrared active gas to be measured and is

only sensitive to this distinct gas with its

characteristic absorption spectrum. The

absorption chamber is sealed with a win-

dow which is transparent for infrared ra-

diation. The window is usually Calcium

Fluoride (CaF

2

).

When the infrared radiation passes

through the reference side of the analysis

cell into the detector, no pre-absorption

occurs. Thus, the gas inside the absorp-

tion chamber is heated, expands and

some of it passes through the flow chan-

nel into the compensation chamber.

When the infrared radiation passes

through the open measurement side of

the analysis cell into the detector, a part

of it is absorbed depending on the gas

concentration. The gas in the absorption

chamber is, therefore, heated less than in

the case of radiation coming from the ref-

erence side. Absorption chamber gas be-

comes cooler, gas pressure in the

absorption chamber is reduced and some

gas from the compensation chamber

passes through the flow channel into the

absorption chamber.

The flow channel geometry is designed in

such a way that it hardly impedes the gas

flow by restriction. Due to the radiation of

the chopper wheel, the different radiation

intensities lead to periodically repeated

flow pulses within the detector.

The Microflow sensor evaluates these

flow pulses and converts them into elec-

trical pulses which are processed into the

corresponding analyzer output.

Figure 1-2. Opto-Pneumatic Gas Detector

Flow channel with

Microflow sensor

Absorption chamber

CaF

2

Window

Compensation chamber