Instruction Manual

748467-A

January 2002

2-14 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Model MicroCEM

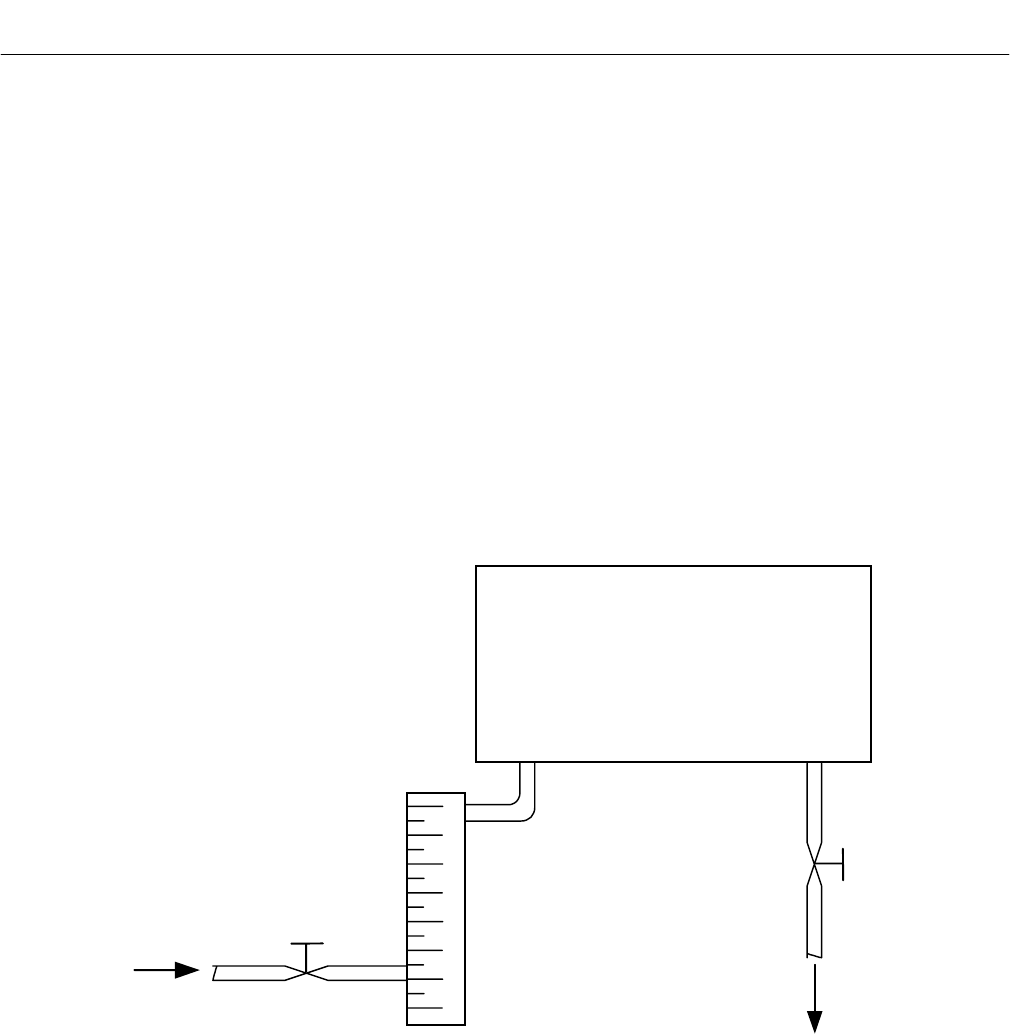

2-5 ANALYTICAL LEAK CHECK

If explosive or hazardous gas samples are

being measured with the MicroCEM, it is rec-

ommended that gas line fittings and compo-

nents be thoroughly leak-checked prior to

initial application of electrical power, bimonthly

intervals thereafter, and after any mainte-

nance which involves breaking the integrity of

the sample containment system.

a. Flow Indicator Method

Supply air or inert gas such as nitrogen,

at 10 psig (689 hPa), to the analyzer

through a flow indicator with a range of 0

to 250 cc/min. Install a shut-off valve at

the sample gas outlet. Set the flow rate to

125 cc/min.

Close the outlet shut-off valve and notice

that the flow reading drops to zero. If the

flow reading does not drop to zero, the

system is leaking and must be corrected

before the introduction of any flammable

sample gas or application of power.

Figure 2-7. Leak Test Flow Method

Flow Meter

N

2

10 psig

(69 kPa)

Gas Outlet

MicroCEM Analyzer

Inlet Outlet