9

MODEL 54e pH/ORP SECTION 3.0

WIRING

pH SENSOR COMPATIBILITY

The following sensors contain solution grounds:

Models 381+, 385+, 396P, 396R

The use of these sensors will allow both glass and ref-

erence diagnostics.

Figure 3-3 shows how these sensors should be wired.

Note that wiring connections depend on whether the

sensor (or junction box) has a preamp or not. If the

sensor (or j-box) has a preamp, then the preamp loca-

tion jumper is moved accordingly and wiring connected

as on the left of Figure 3-3. Otherwise, the jumper is

moved to the "analyzer" position and wiring for TB1 is

connected as on the right hand side.

Junction box (P/N 23550-00) wiring for sensors that

contain a preamp is strictly point to point. All sensor

leads are run to the junction box and carried through by

the extension cable (P/N 9200273). Only use this rec-

ommended extension cable and be careful to connect

all cable leads in the junction box. Sensors without pre-

amps that require cable extension should be wired up

to the junction box (P/N 23555-00) as per the appropri-

ate sensor instruction manual.

The following sensors do not contain solution grounds

but are compatible with the Model 54e pH/ORP:

Models 389-02-54, 396-54, 397-54, 399-09

Sensors without solution grounds must be wired differ-

ently (see Figure 3-6). Diagnostics will only be possible

on the glass electrode side of the sensor.

When extending cable, the junction box with preamp

(P/N 23555-00) must be used. See Figure 3-7 for

wiring details.

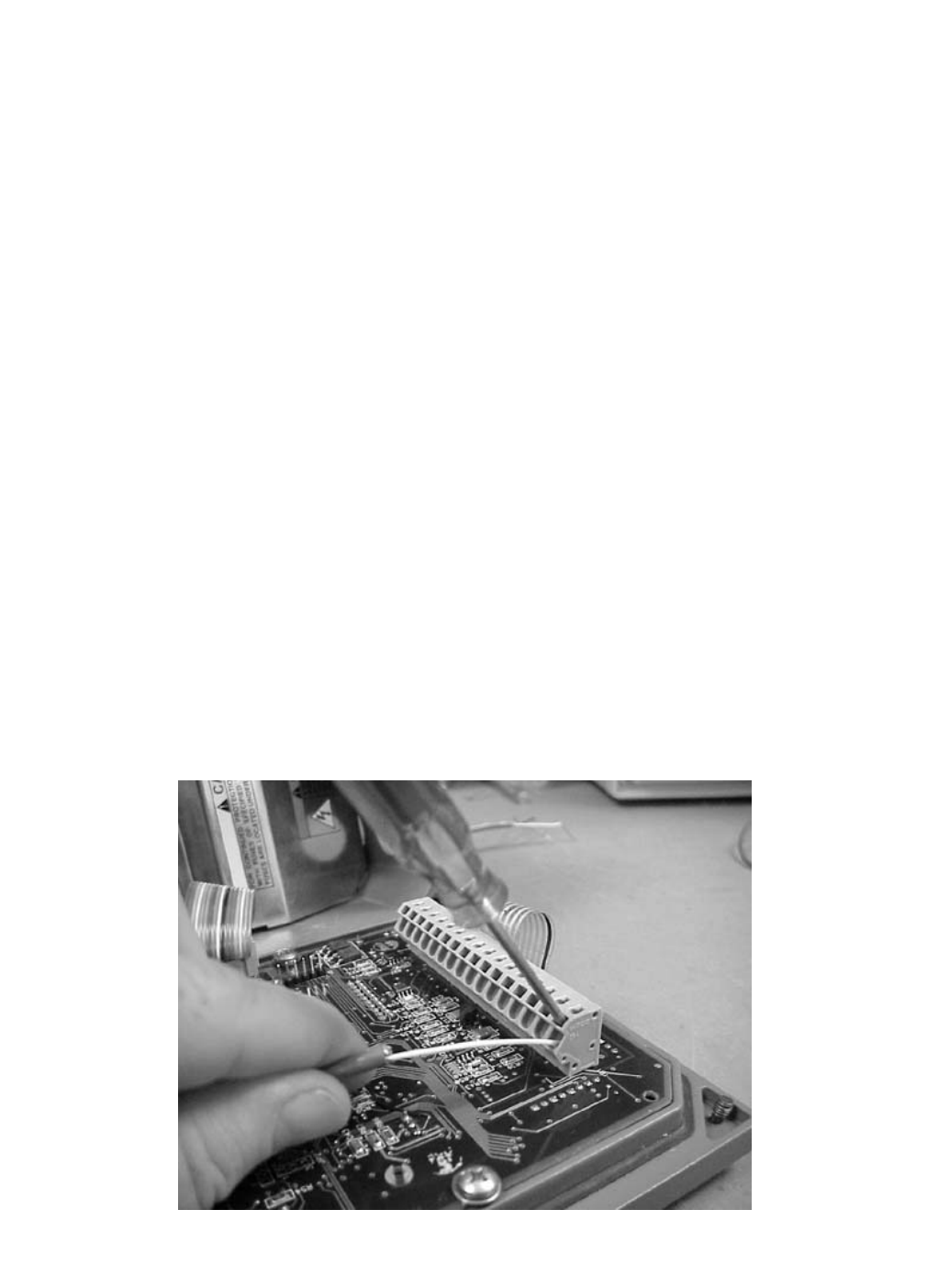

3.5 pH SENSOR WIRING

Be sure that the pH sensor has been properly installed

and mounted. Wire the sensor to the junction box (if so

equipped) and/or Model 54e pH/ORP according to

Figures 3-5 through 3-7, or use the wiring diagram

drawing included inside the controller. Use a narrow-

bladed screwdriver to facilitate sensor wiring (see

Figure 3-2).

The wiring diagrams show connections between

the Model 54e pH/ORP and the junction box used

where distance from the sensor to the controller

exceeds the integral sensor cable length and inter-

connecting wire is required. The interconnecting

sensor wire recommended is P/N 9200273. Use of

this cable provides EMI/RFI protection and com-

plete sensor diagnostics (for sensors so

equipped). The maximum interconnecting wire

length is 500 ft.

IMPORTANT

All interconnecting sensor cable ends must be

properly dressed, as shown in Figure 3-4, to pre-

vent the individual sensor and shield wires from

shorting. All shields must be kept electrically sep-

arate all the way back to the terminals on the Model

54e pH/ORP. Check that there is no continuity

between the shield wires and any other sensor

conductors or shields prior to connecting the sen-

sor wiring to the terminals on the Model 54e

pH/ORP. FAILING TO FOLLOW THESE INSTRUC-

TIONS WILL RESULT IN CONTROLLER MALFUNC-

TION.

FIGURE 3-2. Sensor Wiring Photo