RFID Applicator Signals

Timing Diagrams for RFID

152

58978L-008 Rev. A RFID Programming Guide 11/14/2008

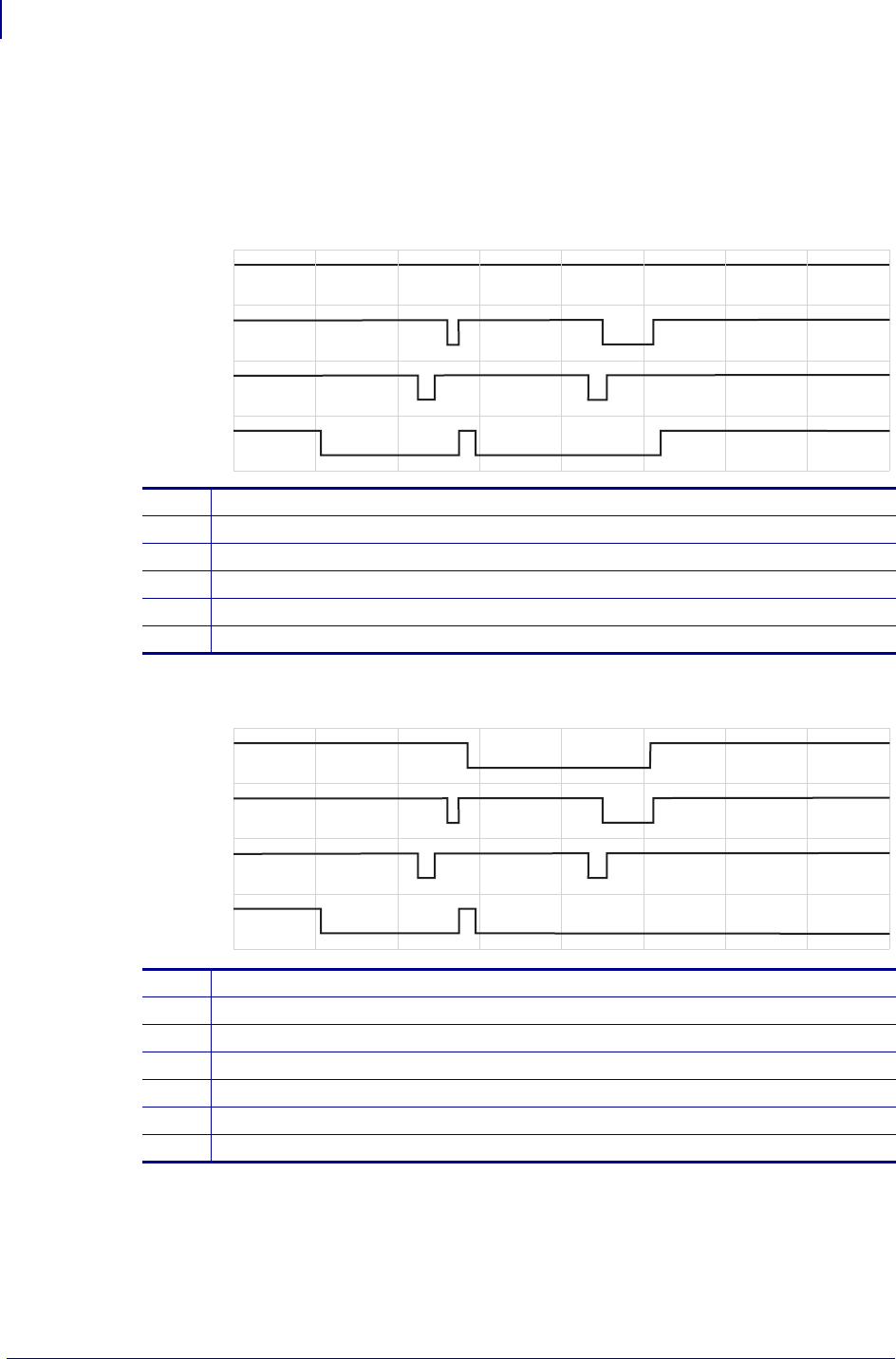

Double Signal Mode

Figure 13 and Figure 14 show the applicator signals for good and bad tags using double signal

mode.

Figure 13 • Double Signal Mode, Good RFID Tag

Figure 14 • Double Signal Mode, Bad RFID Tag

Start Print

(pin 3)

Data Ready

(pin 14)

End Print

(pin 11)

Void

(pin 15)

1

2

3

45 6

1

Label ready for printing.

2

After receiving start print signal, print first part of label.

3

When program position is reached, stop and encode RFID tag.

4

Check void signal (high means good tag).

5

Wait for second start signal.

6

Print second part of label.

Start Print

(pin 3)

Data Ready

(pin 14)

End Print

(pin 11)

Void

(pin 15)

1

2

3

45 7

6

1

Label ready for printing.

2

After receiving start print signal, print first part of label.

3

When program position is reached, stop and encode RFID tag.

4

Check void signal (low means bad tag).

5

Wait for second start signal.

6

Void remainder of label (if applicable).

7

Discard bad label. Data Ready stays low if format to be retried on next label.