EPSON Stylus Pro 7000 Revision B

Maintenance General Maintenance Issues 207

6.1.3 Important Maintenance Items During Service

Operations

Check the following items during printer maintenance/service and perform

any necessary operations.

6.1.4 Lubrication and Glue

Unlike the EPSON Stylus Pro 9000, this printer requires some grease and glue

as described below.

Table 6-3. Items to be Checked During Maintenance/Service

Items Check Points Remedy

Lower Paper Guide

and the surface of the

Subplaten

Make sure no paper,

dust, or foreign objects

are attached or have

accumulated.

Cleaning (If there is an

ink stain, wipe with

dry, clean cloth after

cleaning the ink stain

with damp cloth.)

Capping position

Make sure there is no

gap between the caps

and printheads when

the carriage is in the

capped position (look

from above)

Loosen the

maintenance bracket

screws, push up the

bracket, and secure the

screws.

T-Fence

(Step ruler)

Make sure no dust or

foreign objects are

attached or have

accumulated, and

make sure it is not

ripped, bent, or

stained.

1) Cleaning

2) Replace if there are

any rips or stains

Rail on the CR guide

frame

Make sure there are no

foreign objects

attached.

Cleaning

P_REAR sensor and

P_FRONT sensor

surface

Make sure no paper,

dust, or foreign objects

are attached or have

accumulated.

Cleaning

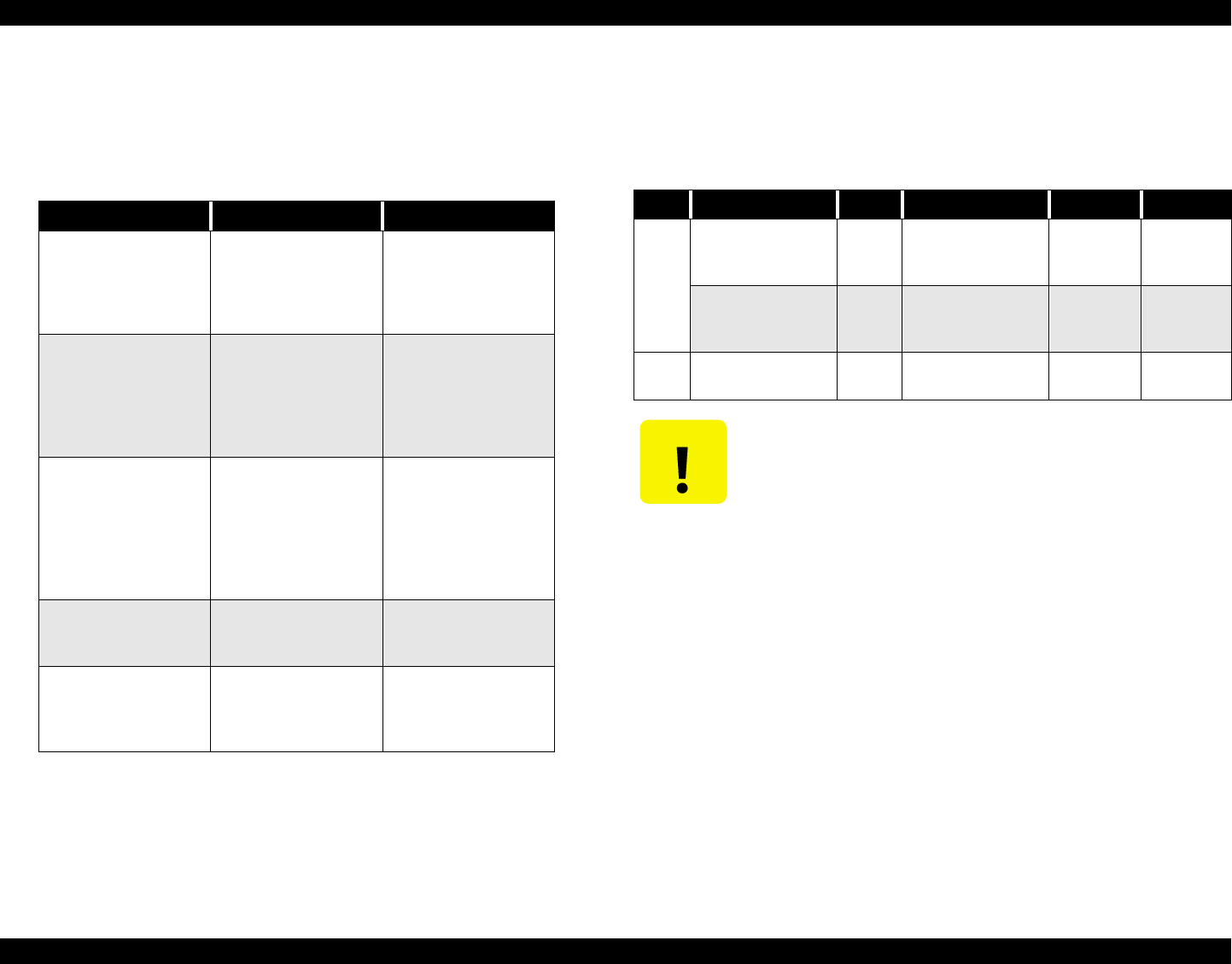

Table 6-4. Grease and Glue Application

Type Name Amount Company Part # Location

Grease

Super-Multi Oil #32 n/a n/a

Carriage

rail

bearings

G-26

(Molicoat EM-60L)

40g

(n/a)

EPSON

(Dow Corning Asia)

B702600001

Other parts

on

mechanism

Glue Screw lock 1,000g EPSON B730200200

Screw lock

(blue)

CAUTION

Do not apply any other oils, lubricants, or glues than those

described in this manual; otherwise printer parts may be

damaged or their useful life may be shortened.