EPSON Stylus Pro 7000 Revision B

Operating Principles Description of Components 65

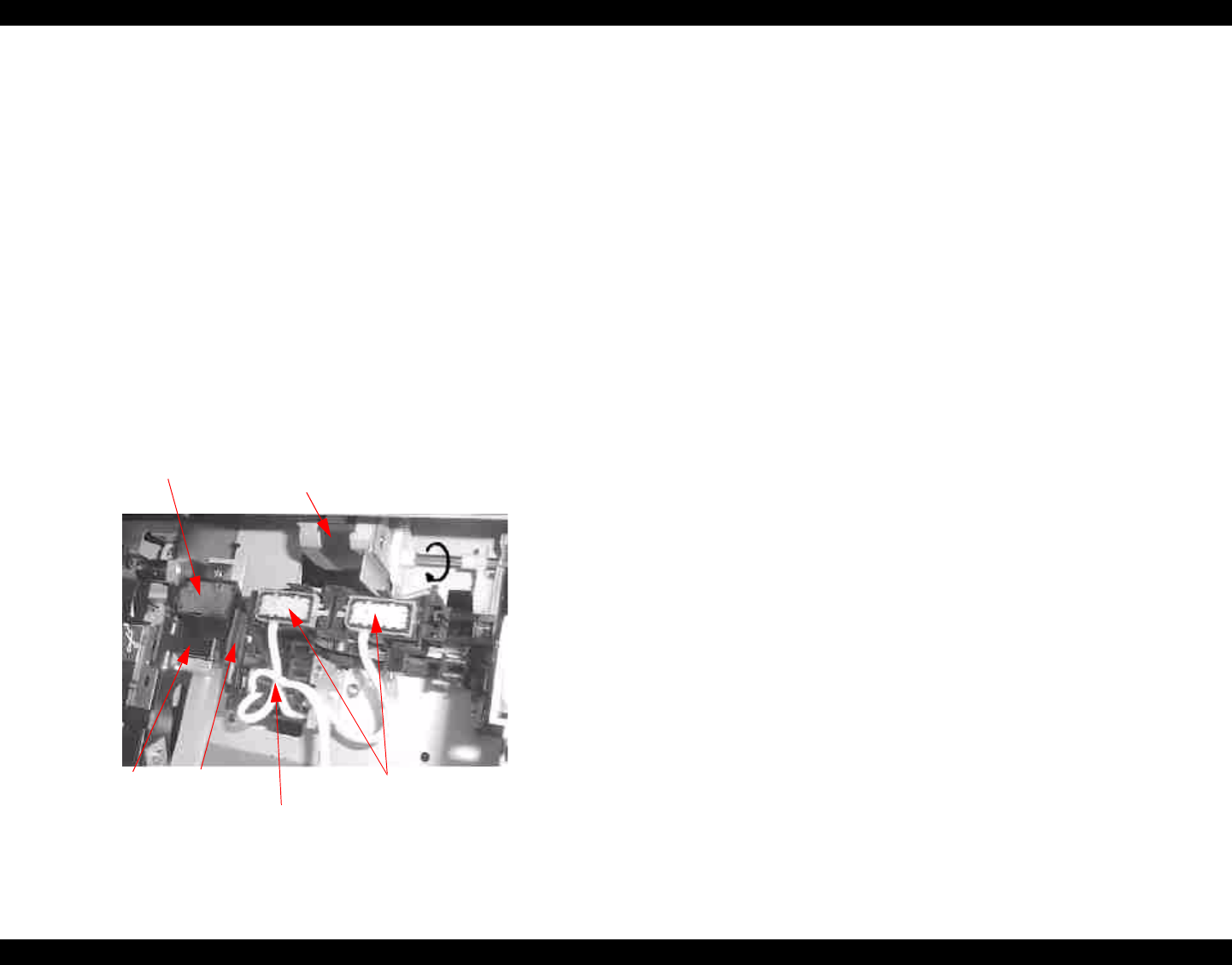

2.2.3 Maintenance Assembly

The maintenance assembly for the SP 7000 is similar to the maintenance

assembly in the EPSON Stylus Pro 9000. If you are not familiar with the SP

9000, see the following for a detailed description.

See Figure 2-5 on page 59 for an illustration of the cleaning. The main

components are:

Pump Assembly (head cleaner)

Pump Motor (stepping motor)

Cap Assembly (B head/C head independent)

Flushing Box

Waste Ink pads

The cleaning mechanism components are installed above the subframe and

some are fixed on the main frame as shown below.

Figure 2-13. Cleaning Mechanism Components

Pump assembly (head cleaner)

When the head is in the capped position (valve closed), the pump motor

creates a vacuum that sucks ink from the nozzles. This is used for

removing ink from the nozzles and nozzle plate, initial ink charge, as well

as cleaning. The waste ink flows through two small tubes to the waste ink

pads.

Head cleaner

The head cleaner has felt on one side and rubber on the other, and is used

to wipe or rub off ink and foreign materials from the nozzle surface.

Pump motor

Clockwise rotation = pump assembly drive for cleaning and so on

Counter clockwise rotation = platen gap adjustment

Cap assembly (one pad for each printhead)

When not printing, the printheads (should) rest on the cap assembly to

make sure the nozzles don’t clog. Also, the printheads are in the capped

position during ink charging, cleaning, and so on.

Flushing box

Flushing (dummy printing) is performed over the flushing box, and the

flushed ink flows through the large diameter tube to the waste ink pads.

Flushing fires a little ink to remove ink that may be drying on the nozzle

surface; performed in between print jobs and sometimes during long

print jobs.

Waste ink pads

The waste ink pads absorb ejected ink through the pump assembly ink

tubes and the flushing box tubes.

When the pads near full, the LCD displays Maintenance Call 0100. When

the pads are completely full, the LCD displays Service Call 00000100. The

pads must be replaced at this time.

Pump

Motor

Pump

rotation = CW

Flushing box

Cap Assembly

Pump Assembly

Head

Cleaner

CR Lock