Teledyne API – T100 UV Fluorescence SO2 Analyzer Instrument Maintenance

225

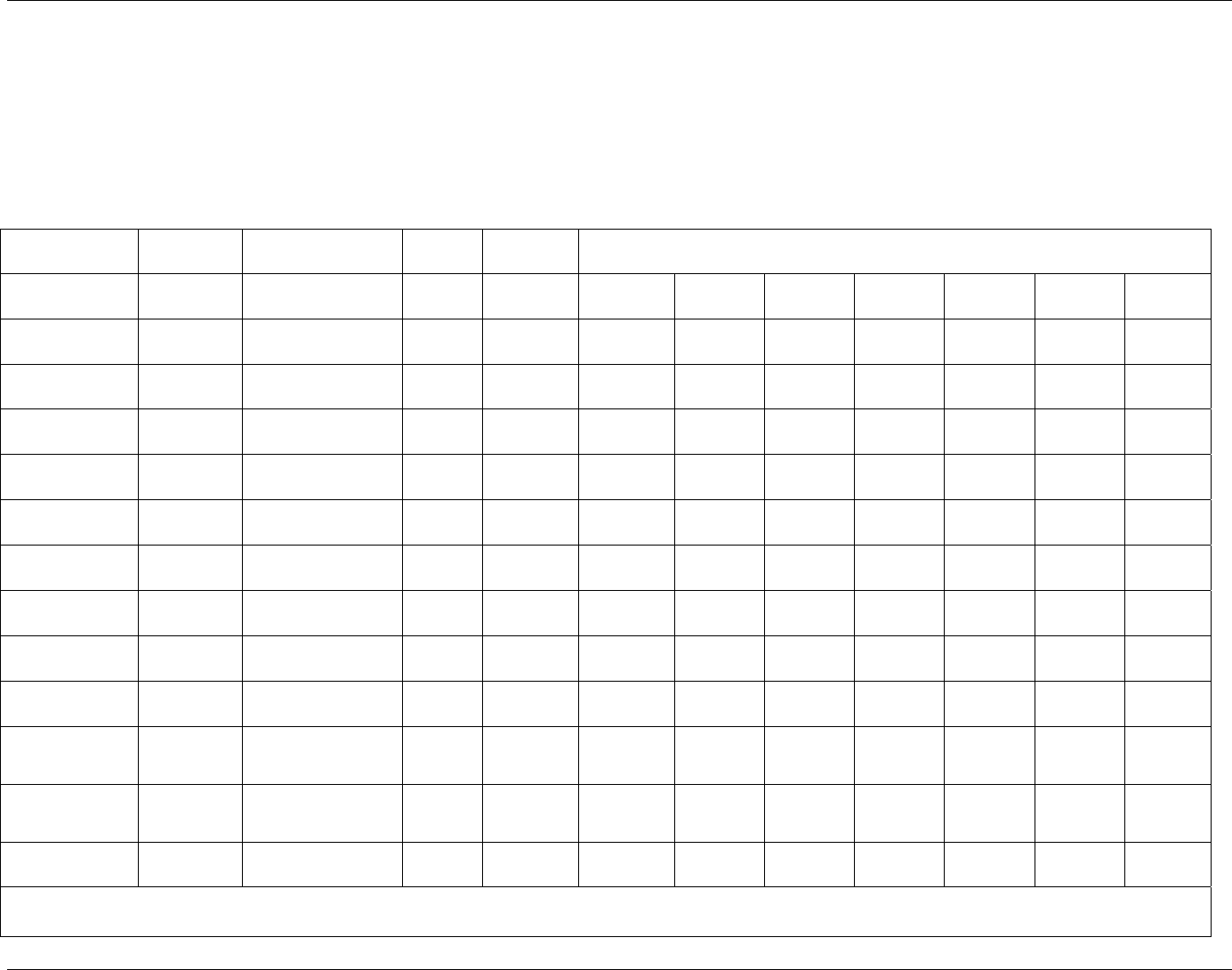

11.1. MAINTENANCE SCHEDULE

Table 11-1 is the recommended maintenance schedule for the T100. Please note that in certain environments with high levels of

dust, humidity or pollutant levels some maintenance procedures may need to be performed more often than shown.

Table 11-1: T100 Preventive Maintenance Schedule

ITEM ACTION FREQUENCY

CAL

CHECK

MANUAL

SECTION

DATE PERFORMED

1

Particulate filter

Change particle

filter

Weekly

No 11.3.1

Verify test functions

Review and

evaluate

Weekly No

11.2;

Appendix

C

Zero/span check

Evaluate offset

and slope

Weekly -- 9.3, 9.6, 9.9

1

Zero/span calibration

Zero and span

calibration

Every 3 months

--

9.2, 9.4, 9.5,

9.7, 9.8

1

External zero air

scrubber (optional)

Exchange

chemical

Every 3 months

No 11.3.3

1

Perform flow check Check Flow Every 6 Months No 11.3.7

Internal IZS

Permeation Tube

Replace Annually YES 11.3.2

Perform pneumatic

leak check

Verify Leak

Tight

Annually or after repairs

involving pneumatics

Yes 11.3.6

2

Pump diaphragm Replace Annually Yes

Refer to

diaphragm kit

instructions

Calibrate UV Lamp

Output

Perform LAMP

CAL

Prior to zero/span

calibration or PMT

hardware calibration

--

5.9.6 &

12.7.2.5

3

PMT sensor

hardware calibration

Low-level

hardware

calibration

On PMT/ preamp

changes if

0.7 < SLOPE or

SLOPE >1.3

Yes 12.7.2.8

1

Sample chamber

optics

Clean

chamber,

windows and

filters

As necessary

Yes

12.7.2.2 &

12.7.2.3

1

Critical flow orifice &

sintered filters

Replace As necessary

Yes 11.3.4

1

These Items are required to maintain full warranty; all other items are strongly recommended.

2

A pump rebuild kit is available from Teledyne API’s Technical Support including all instructions and required parts (refer to Appendix B for part numbers).

3

Replace desiccant bags each time the inspection plate for the sensor assembly is removed.

06807C DCN6650