Troubleshooting & Service Teledyne API - T100 UV Fluorescence SO2 Analyzer

244

12.2.3. RELAY BOARD STATUS LEDS

The most important status LED on the relay board is the red I

2

C Bus watch-dog LED,

labeled D1 (or W/D), which indicates the health of the I

2

C communications bus. This

LED is located in the upper left-hand corner of the relay board when looking at the

electronic components. If D1 is blinking, then the other LEDs can be used in

conjunction with the DIAG menu I/O functions to test hardware functionality by

switching devices on and off and watching the corresponding LED turn on or off. The

LED only indicates that the logic signal for an output has been activated. If the output

driver (i.e. the relay or valve driver IC) is defective, then the LED will light up, but the

attached peripheral device will not turn on.

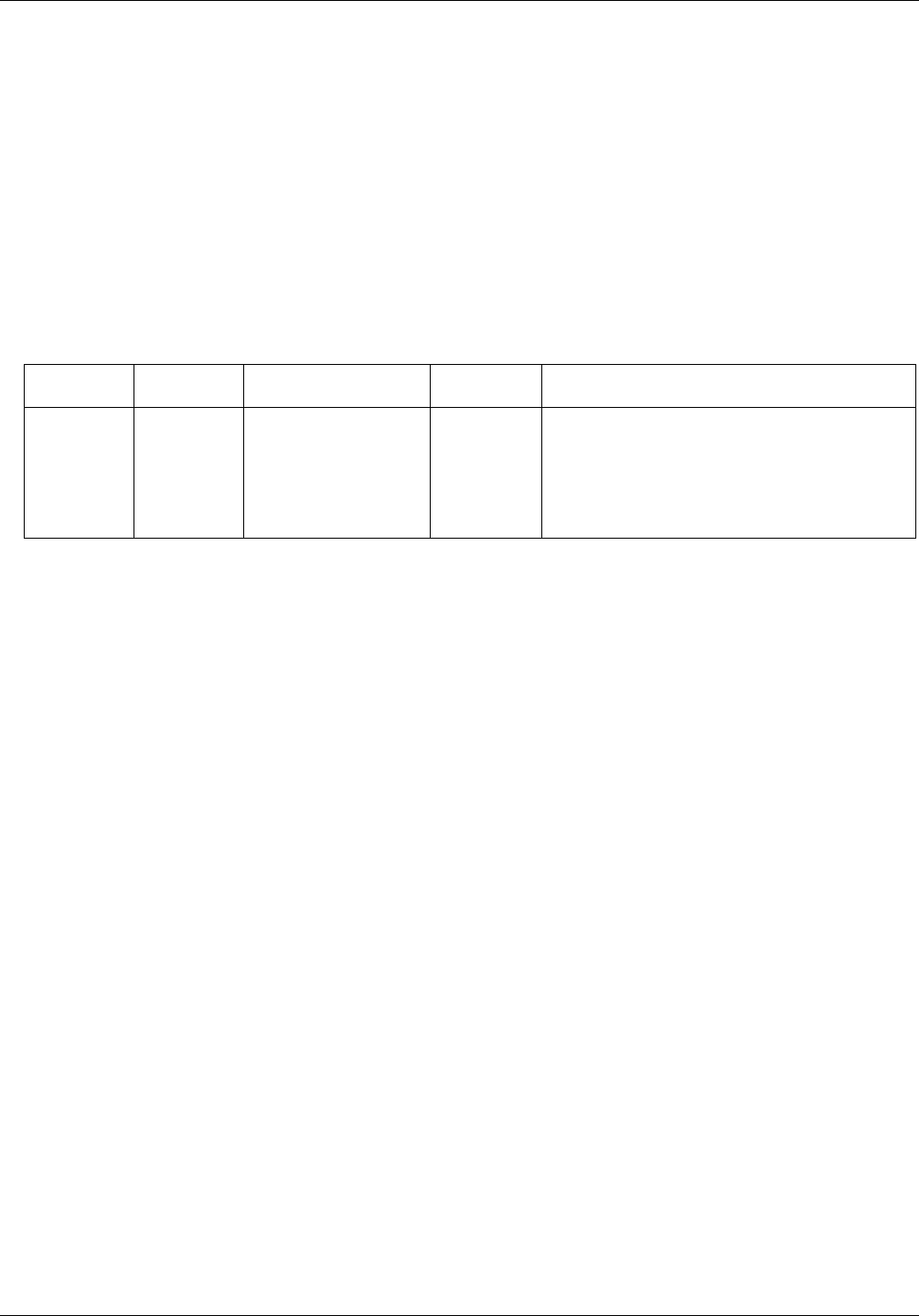

Table 12-3: Relay Board Status LEDs

LED COLOR FUNCTION

FAULT

STATUS

INDICATED FAILURE(S)

D1 red

Watchdog Circuit; I

2

C

bus operation.

Continuously

ON or OFF

Failed/Halted CPU

Faulty Mother Board, Valve Driver board or

Relay PCA

Faulty Connectors/Wiring between Motherboard,

Valve Driver board or Relay PCA

Failed/Faulty +5 VDC Power Supply (PS1)

12.3. GAS FLOW PROBLEMS

The standard analyzer has one main flow path. With the IZS option installed, there is a

second flow path through the IZS oven that runs whenever the IZS is on standby to

purge SO

2

from the oven chamber. The IZS flow is not measured so there is no reading

for it on the front panel display. The full flow diagrams of the standard configuration

(refer to Figure 3-18) and with options installed (refer to Figure 3-19 and Figure 3-20)

help in trou

bleshooting flow problems. In general, flow problems can be divided into

three categories:

Flow is too high

Flow is greater than zero, but is too low, and/or unstable

Flow is zero (no flow)

When troubleshooting flow problems, it is essential to confirm the actual flow rate

without relying on the analyzer’s flow display. The use of an independent, external flow

meter to perform a flow check as described in Section 12.5.2 is essential.

12.3.1. ZERO OR LOW SAMPLE FLOW

If the pump is operating but the unit reports a XXXX gas flow, do the following three

steps:

Check for actual sample flow

Check pressures

Carry out a leak check

To check the actual sample flow, disconnect the sample tube from the sample inlet on

the rear panel of the instrument. Ensure that the unit is in basic SAMPLE mode. Place a

06807C DCN6650