Teledyne API - T100 UV Fluorescence SO2 Analyzer Getting Started

59

IMPORTANT

Leak Check:

Run a leak check once the appropriate pneumatic connections have

been made; check all pneumatic fittings for leaks using the

procedures defined in Section 11.3.6.

CAUTION – GENERAL SAFETY HAZARD

Gas flow though the analyzer must be maintained at all time for units with

a permeation tube installed. Insufficient gas flow allows gas to build up

to levels that will contaminate the instrument or present a safety hazard

to personnel.

Section 3.3.2.1 provides external pneumatic connection instructions, and Table 3-9

provides links to the location of various internal pneumatic layout illustrations.

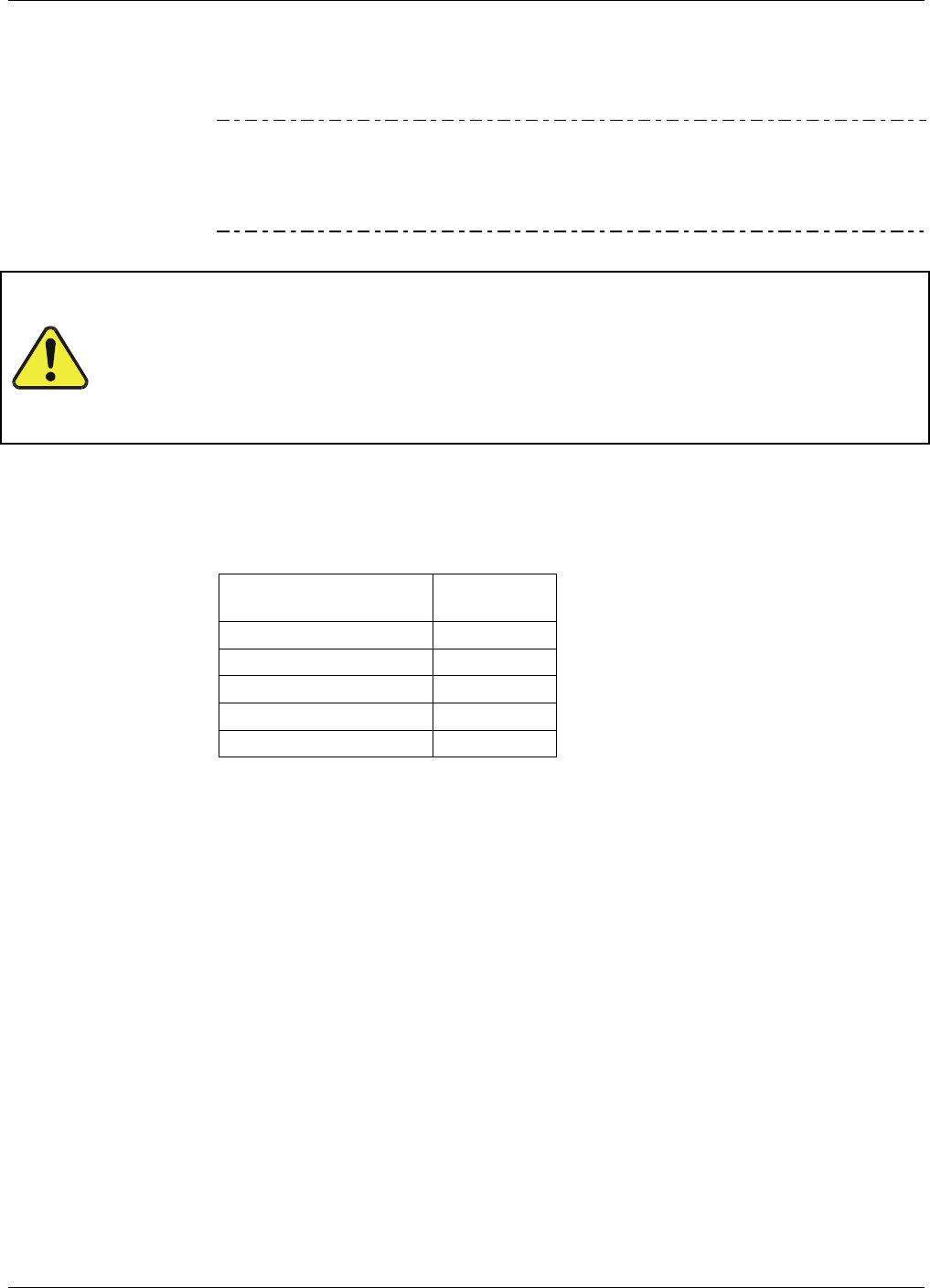

Table 3-9: Pneumatic Layout Reference

Pneumatic Layout Section

Basic 3.3.2.2

Zero/Span Valves 3.3.2.3

Internal Zero/Span (IZS) 3.3.2.4

Basic with O2 Sensor 3.3.2.8

Basic with CO2 Sensor 3.3.2.9

3.3.2.1. BASIC CONNECTIONS INCLUDING W/SPAN GAS AND W/GAS DILUTION CALIBRATOR

Refer to Figure 3-4 and Table 3-3 while making the pneumatic connections as follows:

SAMPLE inlet

Connect ¼” gas line not more than 2 m long, from sample gas

source to this inlet.

When no zero/span/shutoff valve options, also connect line from

calibration gas source to this inlet, but only when a calibration

operation is actually being performed.

EXHAUST outlet Connect exhaust line made of PTEF tubing; minimum O.D ¼”, to

this fitting. The exhaust line should be no longer than 10 meters,

and should lead outside the shelter or immediate area surrounding

the instrument.

Figure 3-16 and Figure 3-17 illustrate pneumatic connections for two of the possible

basic configurations.

06807C DCN6650